Shaft end hole machining method for motor shaft of balance car

A hole processing and motor shaft technology, which is applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of low processing efficiency, high production cost, and large difference in coaxiality, etc., so as to improve processing efficiency and universal The effect of improving the performance and improving the coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

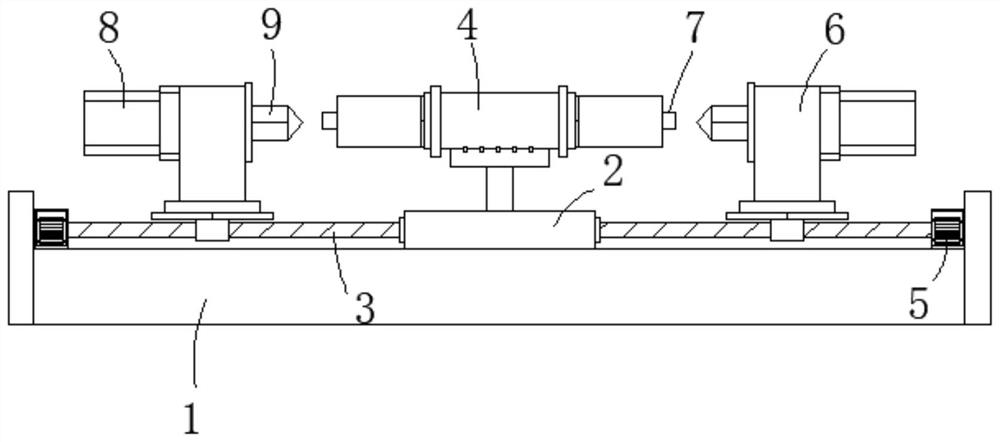

[0030] like Figure 1-5 As shown, a motor shaft end hole processing device of a balance car includes a base 1, a mounting seat 2, a driving mechanism, and a sliding seat 6. The mounting seat 2 is located in the middle position on the base 1, and both ends of the mounting seat 2 in the horizontal direction are provided with There is a sliding seat 6 , a shaft fixing mechanism 4 is horizontally arranged on the mounting seat 2 , and a processing electrical device is fixed on the sliding seat 6 .

[0031] In the present application, a shaft fixing mechanism 4 is provided on the mounting seat 2 to fix the shaft 7 to be processed, and two sliding seats 6 are provided on the mounting seat 2, so that the two shaft members or both ends of the same shaft member can be fixed at the same time. processing to improve processing efficiency.

[0032] It should be noted that, in the present application, the machining electrical devices can be various tools for shaft end holes, such as chamfer...

Embodiment 2

[0048] like Figure 1-5 As shown, a motor shaft end hole processing device of a balance car includes a base 1, a mounting seat 2, a driving mechanism, and a sliding seat 6. The mounting seat 2 is located in the middle position on the base 1, and both ends of the mounting seat 2 in the horizontal direction are provided with There is a sliding seat 6 , a shaft fixing mechanism 4 is horizontally arranged on the mounting seat 2 , and a processing electrical device is fixed on the sliding seat 6 .

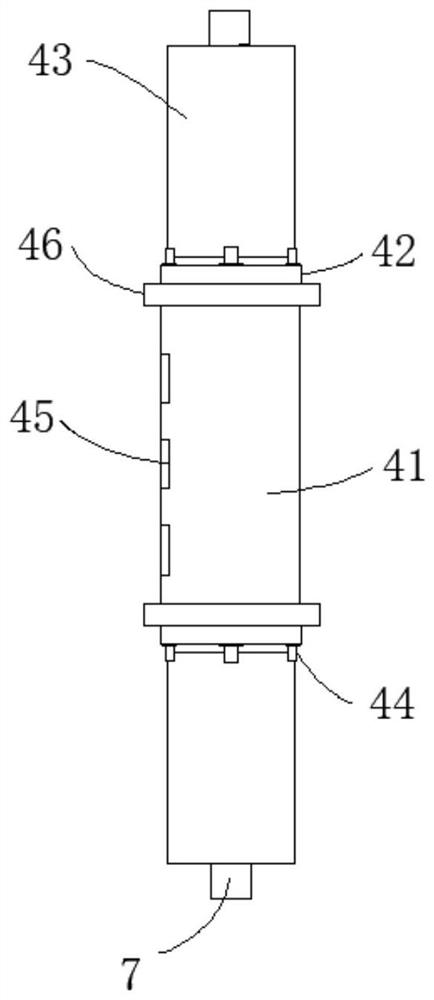

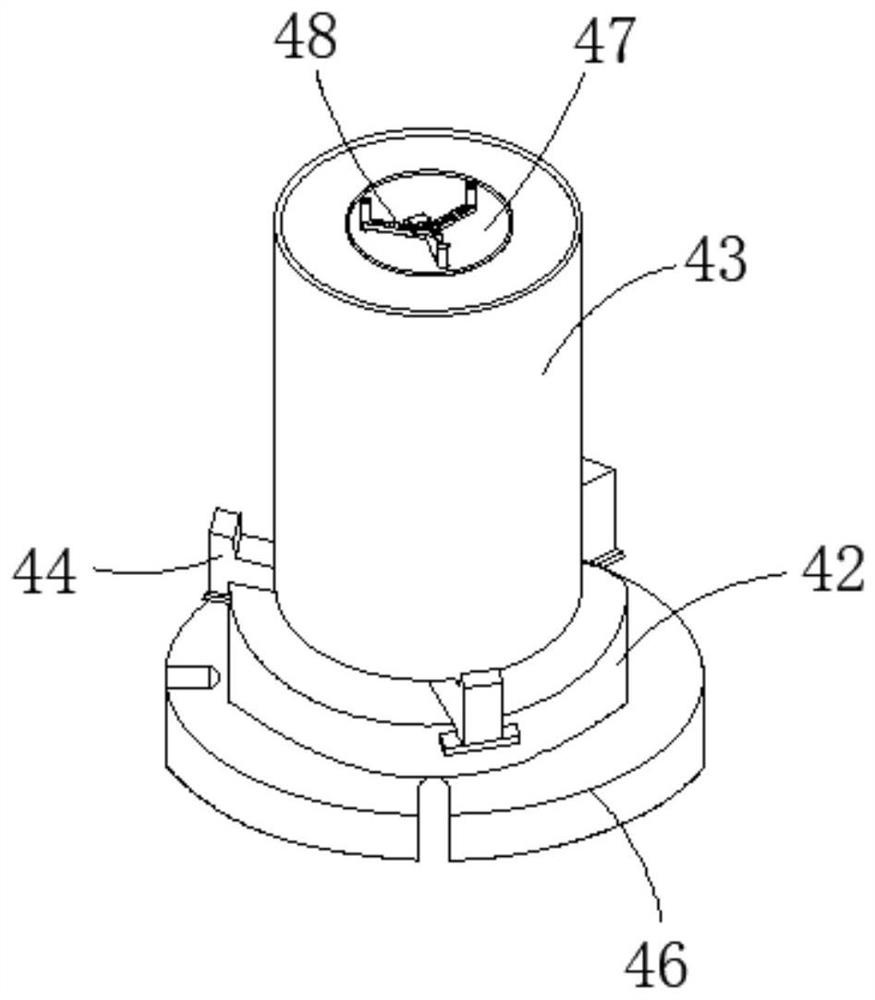

[0049] The shaft fixing mechanism 4 includes an installation cylinder 41 , side cylinders 43 symmetrically arranged at both ends of the installation cylinder 41 , and detachable limit components arranged inside the installation cylinder 41 and the side cylinder 43 , wherein the side cylinder 43 and the installation cylinder 41 are movable between By engaging, it is convenient to disassemble and assemble the side cylinder 43 , and it is also convenient to install the shaft 7 to be proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com