Treatment method and treatment device for water-based waste solvent

A treatment method and waste solvent technology, which is applied in the field of water-based waste solvent treatment method and its treatment device, can solve the problems of affecting membrane separation performance and service life, frequent membrane replacement, and increasing operating costs, so as to achieve environmental reduction and resource efficiency, reduce membrane fouling, and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

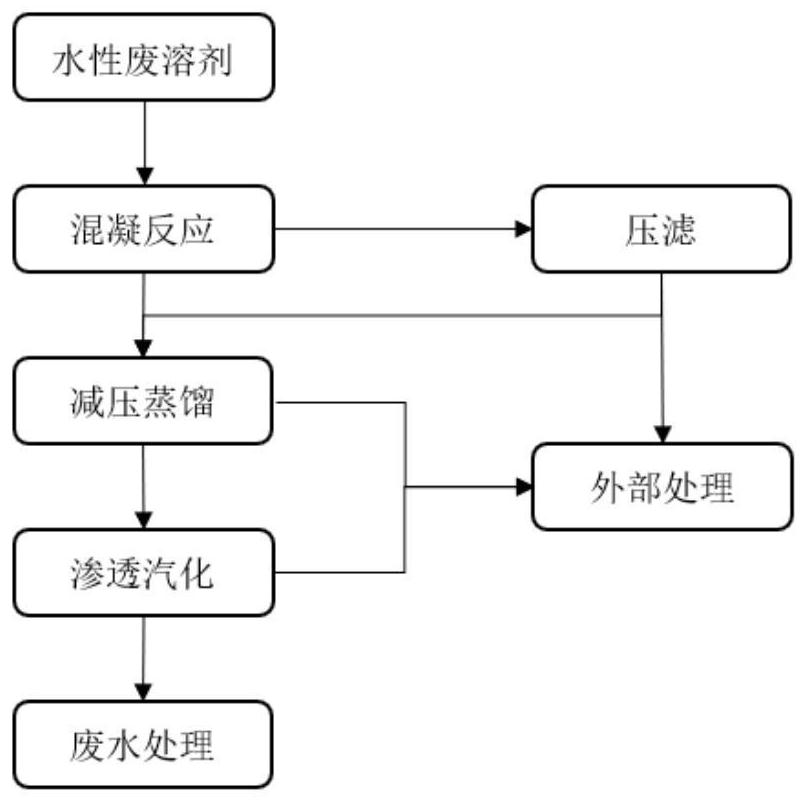

[0036] like figure 1 As shown, the present embodiment provides a method for treating aqueous waste solvent, the steps comprising:

[0037] S1. The aqueous waste solvent is transported to the coagulation reaction device 1, and an appropriate amount of coagulant is transported to the coagulation reaction device 1. After the aqueous waste solvent is stirred and reacted completely, the supernatant is It is transported to the vacuum distillation device 2, and the sedimented sludge is transported to the filter press device 4;

[0038] Wherein, in the coagulation reaction device 1, the stirring speed is 200r / min~400r / min, the pH of the reaction is 6~8, the reaction time is 15min~45min, and the standing time is 15min~45min;

[0039] S2, after the precipitation sludge is completed by pressure filtration, the filtrate is transported to the vacuum distillation device 2, and the mud cake is transported to the external treatment section;

[0040] Wherein, in the vacuum distillation devic...

Embodiment 2

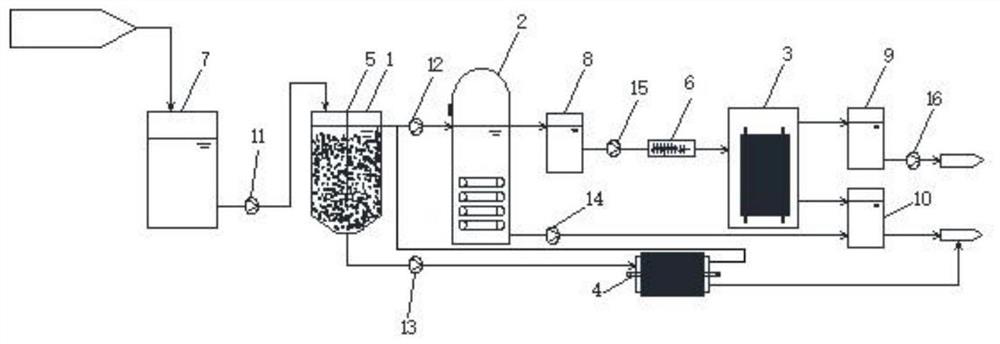

[0045] like figure 2 As shown, this embodiment provides an aqueous waste solvent treatment system, which is suitable for the treatment method described in Embodiment 1, including: a coagulation reaction device 1, a vacuum distillation device 2, a pervaporation device 3, and a filter press device 4. Stirring device 5, heating device 6, first liquid storage device 7, second liquid storage device 8, third liquid storage device 9, fourth liquid storage device 10, first liquid pump 11, second liquid pump 12, The third liquid pump 13, the fourth liquid pump 14, the fifth liquid pump 15 and the sixth liquid pump 16;

[0046] Wherein, the first liquid storage device 7 is connected to the coagulation reaction device 1 , the liquid outlet of the coagulation reaction device 1 is connected to the vacuum distillation device 2 , and the second liquid outlet of the vacuum distillation device 2 is connected to the vacuum distillation device 2 . A liquid outlet is connected to the second liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com