Low-cost plasticizer for PVC (polyvinyl chloride) and preparation method thereof

A plasticizer, low-cost technology, applied in the field of plasticizers for PVC, can solve the problem of difficult utilization of trimellitic anhydride heavy component by-products, achieve low cost, good performance, and solve the effects of difficult utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

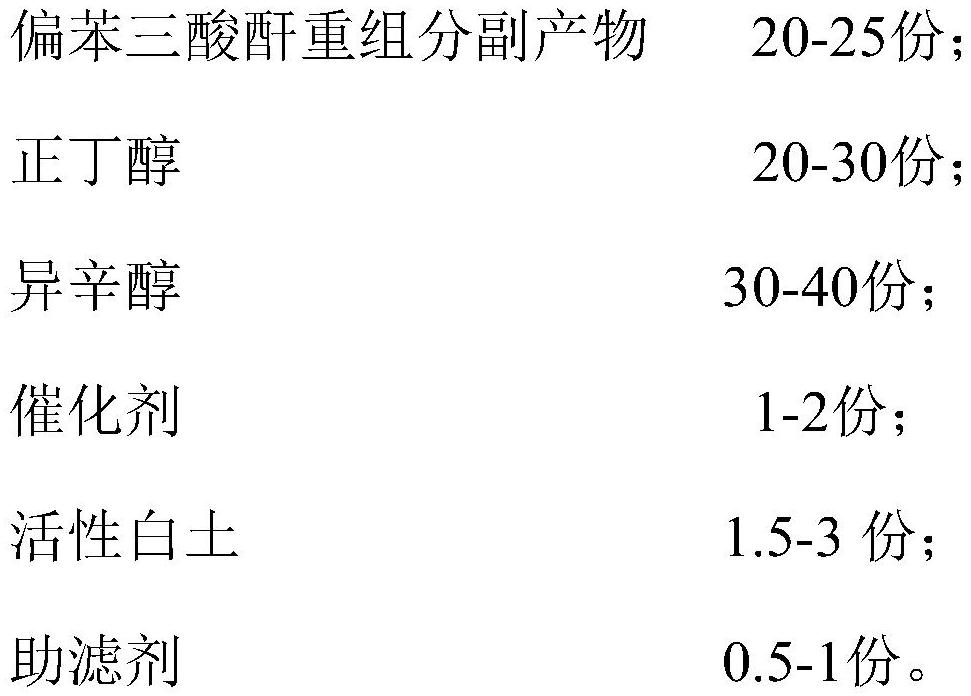

[0028] A low-cost plasticizer for PVC, the mass parts of the raw materials are as follows:

[0029]

[0030] The activated clay model is qzh-01, which was purchased from Henan Qingzhihong Environmental Protection Technology Co., Ltd.;

[0031] The catalyst can be tetrabutyl titanate;

[0032] The filter aid is white diatomaceous earth with a particle size of 100 mesh, purchased from Shuolong Mineral Products Processing Plant in Lingshou County.

[0033] The preparation method of the low-cost PVC plasticizer comprises the following steps:

[0034] A. Add n-butanol, trimellitic anhydride heavy component by-product and catalyst according to the formula, stir evenly, then heat up to 120°C to carry out the esterification reaction with water;

[0035] B. Sampling to detect the acid value of the esterified product, when the acid value of the esterified product is reduced to 110 mgKOH / g, add the isooctanol of the formula amount, heat up to 190 °C and carry out high temperature se...

Embodiment 2

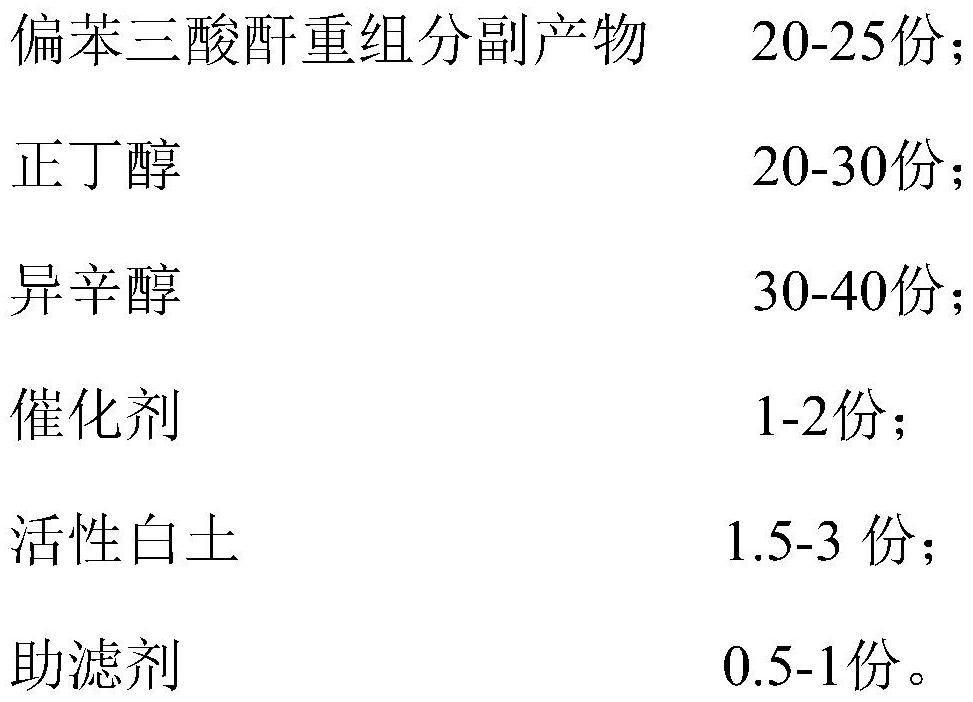

[0040] A low-cost plasticizer for PVC, the mass parts of the raw materials are as follows:

[0041]

[0042]

[0043] Described low-cost PVC plasticizer, wherein the activated clay model can be qzh-01, purchased from Henan Qingzhihong Environmental Protection Technology Co., Ltd.;

[0044] The catalyst can be tetrabutyl titanate;

[0045] The filter aid can be white diatomite with a particle size of 100 mesh (for example, purchased from Lingshou County Shuolong Mineral Products Processing Plant).

[0046] The preparation method of the low-cost PVC plasticizer comprises the following steps:

[0047] A. Add n-butanol, trimellitic anhydride heavy component by-product and catalyst according to the formula, and after stirring evenly, heat up to 122°C to carry out the esterification reaction with water;

[0048] B. Sampling to detect the acid value of the esterified product, when the acid value of the esterified product is reduced to 120 mgKOH / g, add the isooctanol of the fo...

Embodiment 3

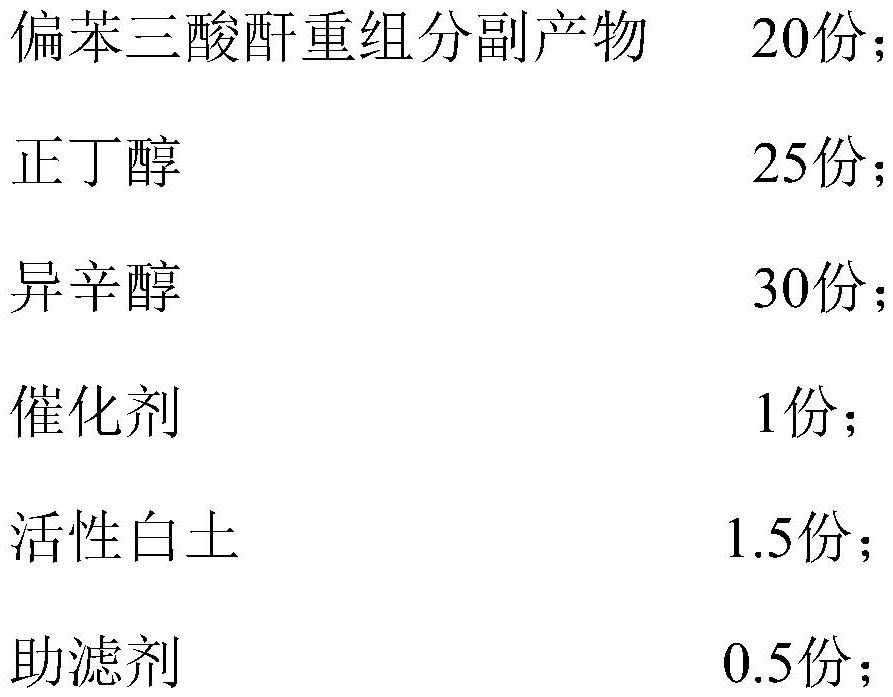

[0053] A low-cost plasticizer for PVC, the mass parts of the raw materials are as follows:

[0054]

[0055] Described low-cost PVC plasticizer, wherein the activated clay model can be qzh-01, purchased from Henan Qingzhihong Environmental Protection Technology Co., Ltd.;

[0056] The catalyst can be tetrabutyl titanate;

[0057] The filter aid can be white diatomite with a particle size of 100 mesh (for example, purchased from Lingshou County Shuolong Mineral Products Processing Plant).

[0058] The preparation method of the low-cost PVC plasticizer comprises the following steps:

[0059] A. Add n-butanol, trimellitic anhydride heavy component by-product and catalyst according to the formula, and after stirring evenly, heat up to 120 ° C to carry out the esterification reaction with water;

[0060] B. Sampling to detect the acid value of the esterified product, when the acid value of the esterified product is reduced to 115 mgKOH / g, add the isooctanol of the formula amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com