Wafer drying method, wafer drying device and chemical mechanical grinding machine

A drying method and wafer drying technology, which is applied in the fields of wafer drying, wafer drying equipment, and chemical mechanical grinding machines. Effects on emissions, superior economic value and environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to solve the problems in the prior art, in the embodiment of the present invention, by selecting a drying liquid with the characteristics of low surface tension, low boiling point, and immiscibility with water, the cleaning liquid that adheres to the surface of the wafer is made of the difference in surface tension. The drops are completely replaced.

[0038] In order to make the objectives, features and beneficial effects of the embodiments of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

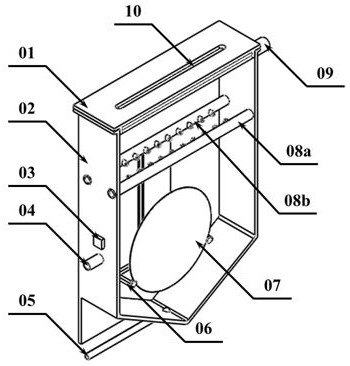

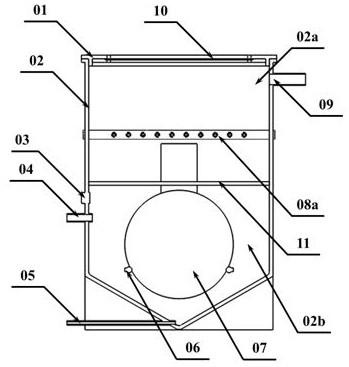

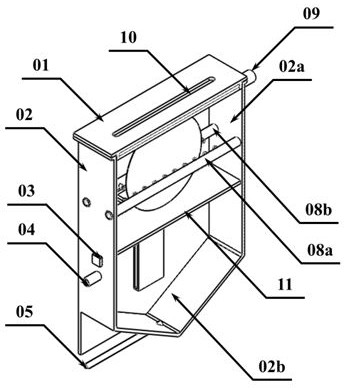

[0039] like figure 1 , figure 2 and image 3 As shown, the wafer drying device includes: a drying box 02, a megasonic wave generating device (not shown in the figure), a first liquid inlet and outlet 05, a second liquid inlet and outlet 04, a liquid level sensor 03, and a thermal insulation sealing plate 11. , the first jet pipe 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com