Variable-temperature fermentation method of cigar tobacco leaves

A technology for cigar tobacco leaves and variable temperature fermentation, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of chemical composition coordination, evaluation of smoking quality changes, and reduce the quality of tobacco leaves, so as to reduce irritation and miscellaneous gas, and reduce alkaloids. content, the effect of improving irritation and miscellaneous air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for fermenting cigar tobacco leaves at variable temperature, comprising the following steps:

[0025] First, add water to the tobacco leaves to re-moisturize the initial moisture to 30%, and set aside.

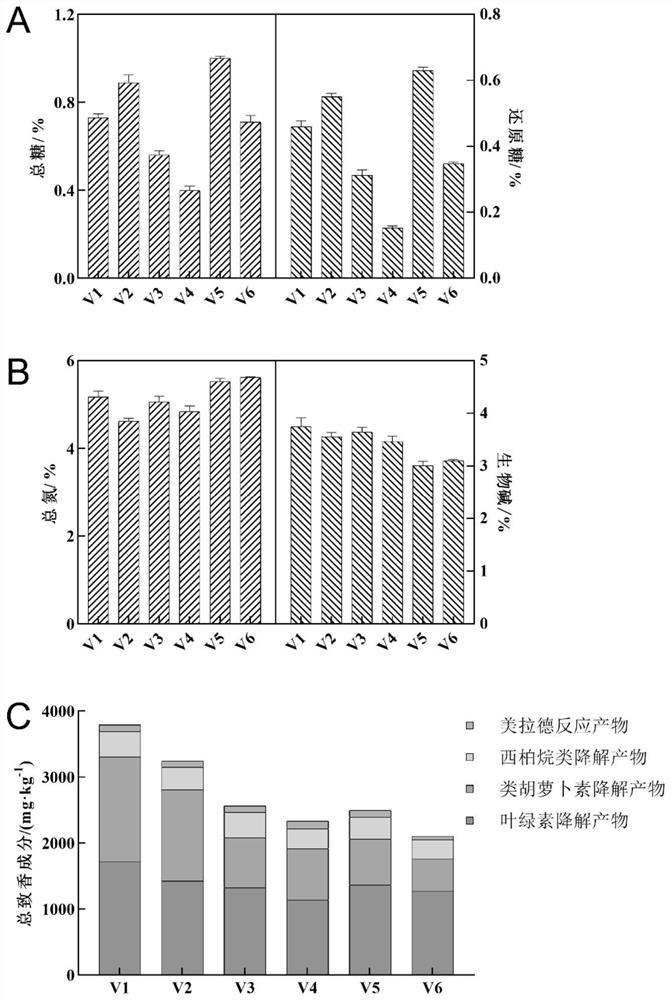

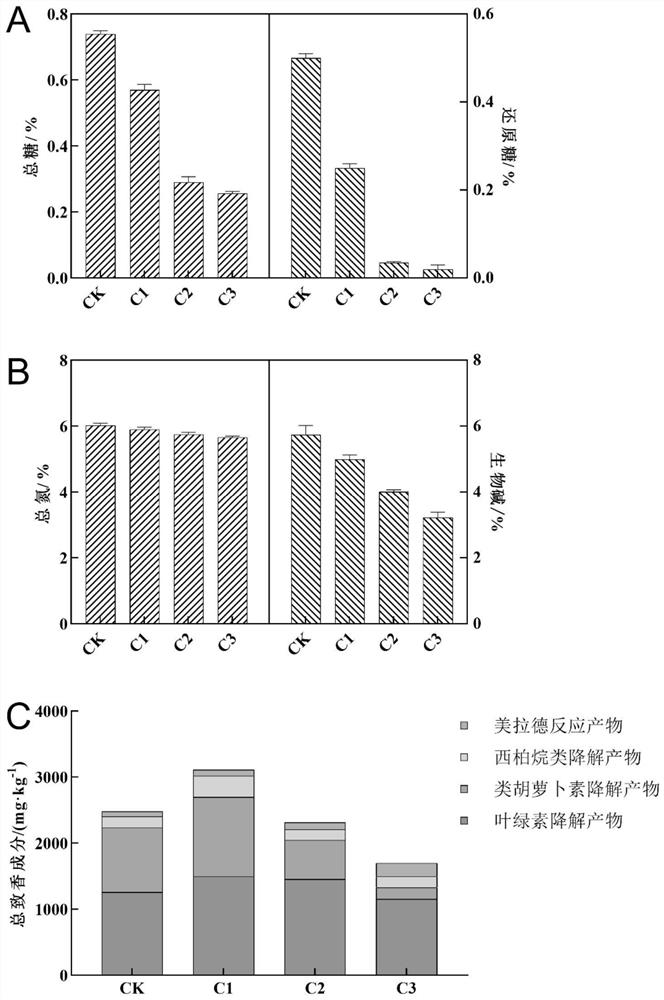

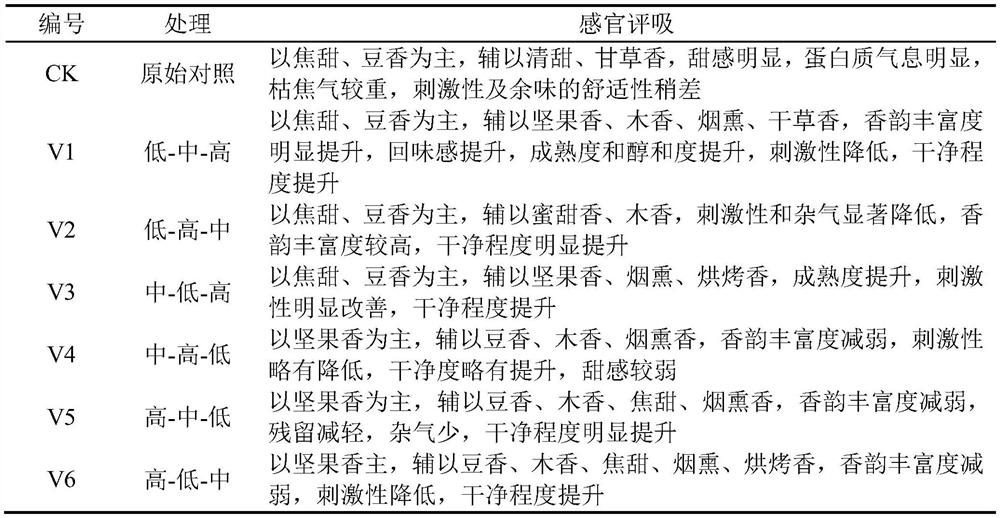

[0026] Secondly, the rejuvenated tobacco leaves were subjected to variable temperature combined fermentation. The combined temperature was 35 °C, 40 °C, and 45 °C. The fermentation was divided into three stages, each stage was fermented for 10 days, and the fermentation time was 30 days in total. The temperature gradient settings are shown in Table 1. .

[0027] Thirdly, the cigar tobacco leaf samples after fermentation were dried and pulverized at 45°C, passed through a sieve with an aperture of 0.25 mm, and the content of total sugar, reducing sugar, total alkaloid and total nitrogen was determined by continuous flow method.

[0028] In the fourth step, the cigar tobacco leaf samples after the fermentation were dried and pulverized at 45° C., passed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com