Human body implant material and preparation method thereof

An implant material and human body technology, applied in the field of medical devices, can solve the problems of inability to form bony fusion, poor osteogenic performance, loose PEEK implants, etc., and achieve good osteoinductive ability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

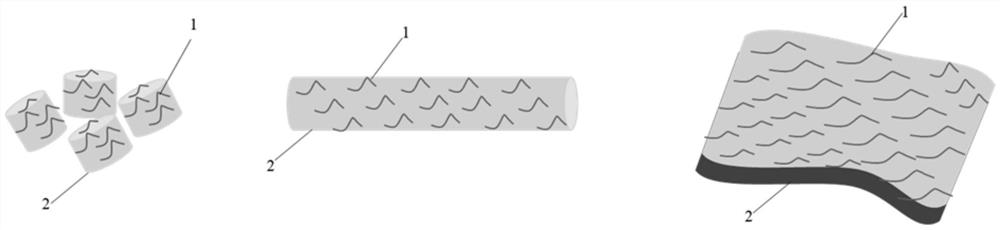

[0037] In this embodiment, the human implant material in the present invention needs to be prepared into a PEEK bone plate. In this embodiment, magnesium alloy is used as the material of the additive 1, and PEEK (450PF) is used as the material of the main body 2. The preparation method of this embodiment is as follows:

[0038] A) Raw material pretreatment: The PEEK (450PF) particles are dried in a vacuum drying oven at a temperature of 160° C. for 24 hours to obtain dried PEEK (450PF) particles; the magnesium alloy material is processed into magnesium fibers with a length of 2 mm and a diameter of 100 μm , and then put the magnesium fiber into a beaker filled with acetone solution for ultrasonic cleaning, the cleaning time is 10min, the surface impurities are washed away, and then washed with distilled water three times and dried.

[0039] B) Weigh 200 g of dried PEEK (450PF) particles and 40 g of dried magnesium fibers, put them into the extruder of SJZS-10B, and connect the...

Embodiment 2

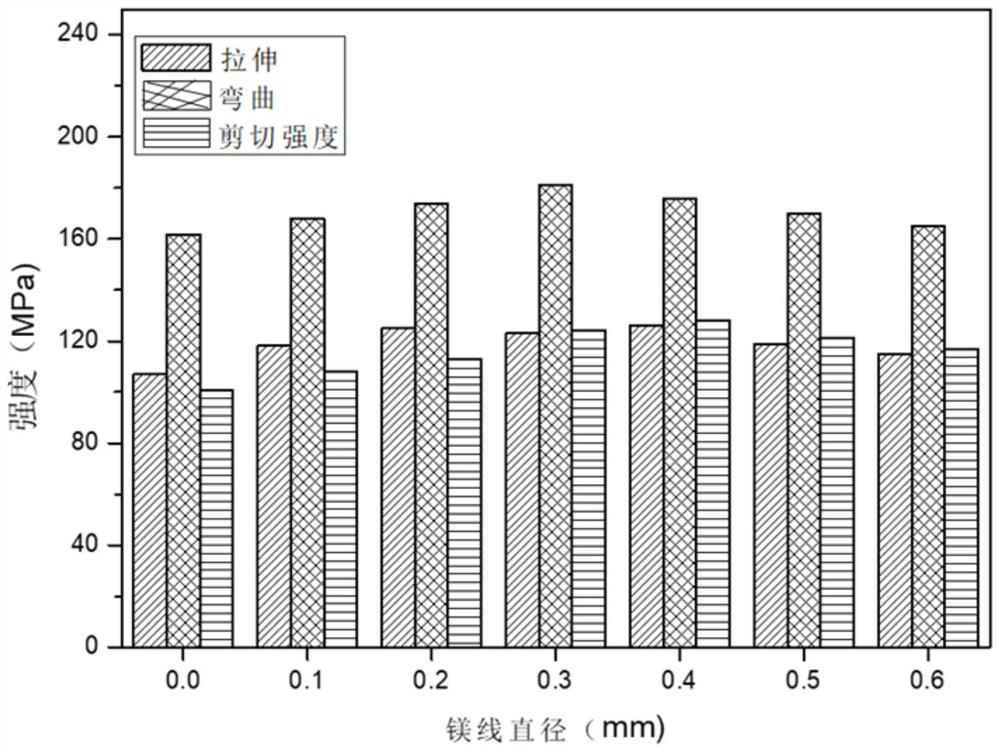

[0043] In this embodiment, the raw material of additive 1 is magnesium fiber with a length of 5 mm, a diameter of 100 μm and a mass of 50 g, and other operation steps are the same as those in the first embodiment.

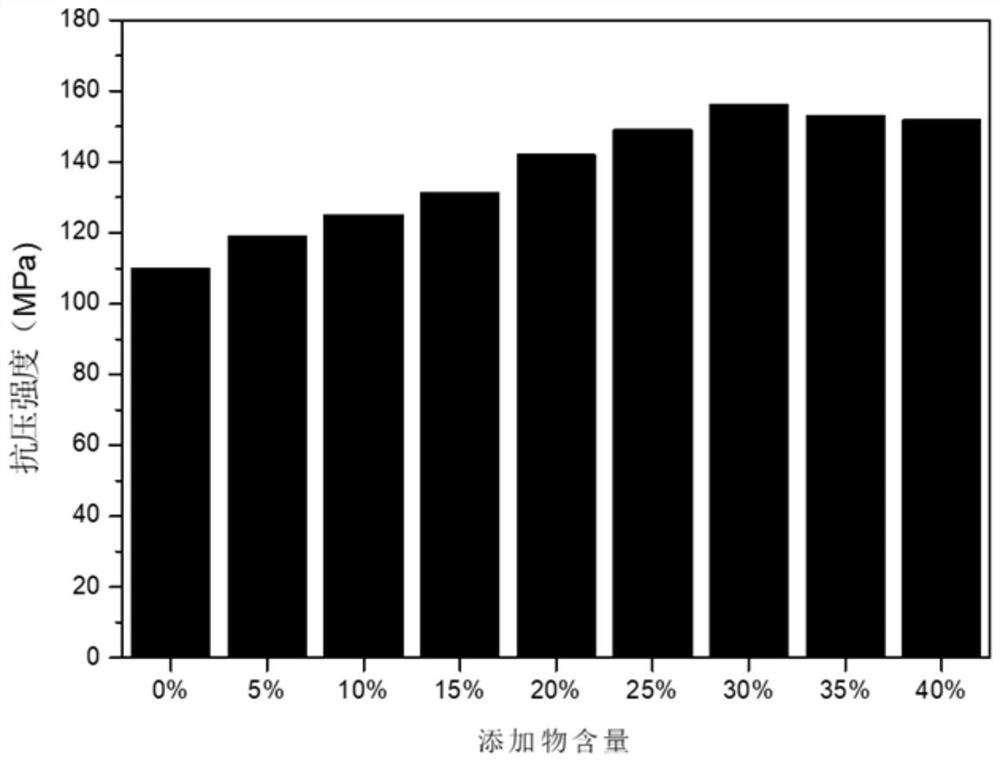

[0044] In the human implant material in this embodiment, the mass percentage of Additive 1 is 20%. like figure 2 As shown, the mechanical properties of this embodiment are better than those of pure PEEK material, and also better than the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com