Composite armor plate with ceramic rod as interlayer and preparation method of composite armor plate

A technology of ceramic rods and armor plates, which is applied to the structure of armor plates and other directions, can solve the problems of low elastic resistance of composite armor plates, easy separation of plate structures, low bonding strength, etc. The effect of good performance and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

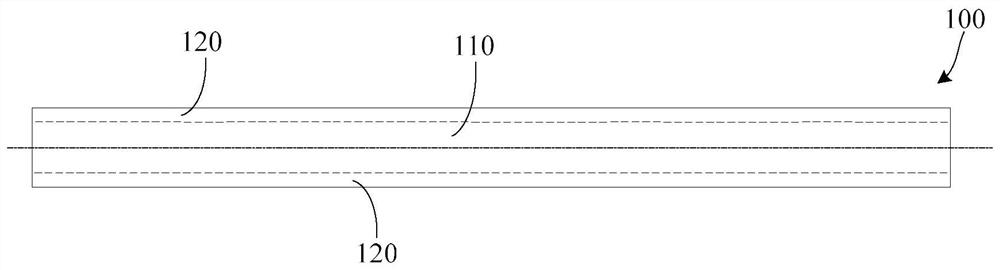

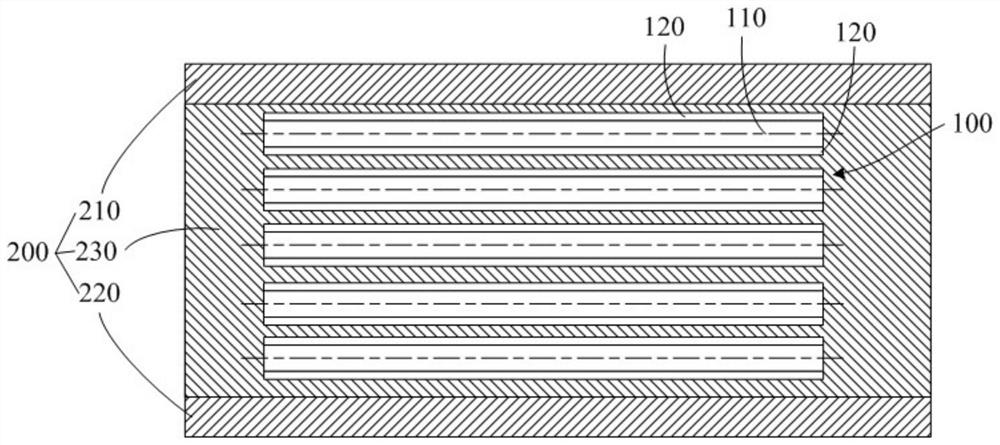

[0018] Please refer to the attached Figure 1-2 , this embodiment provides a composite armor plate with a ceramic rod 100 as a sandwich, including:

[0019] The armor plate layer 200 and the ceramic rod 100, the armor plate layer 200 wraps the ceramic rod 100, and the ceramic rod 100 itself includes the ceramic rod core 110 and the outer composite layer 120, which are formed by integral hot pressing and sintering.

[0020] The composite layer structure is a multi-layer superposed composite structure of titanium carbide and aluminum oxide.

[0021] Wherein, in the direction away from the ceramic core, the content of titanium carbide in the multi-layer composite ceramic layer increases, and the content of alumina decreases.

[0022] Among them, the ceramic rod 100 is in the shape of a round rod.

[0023] The number of ceramic rods 100 is several layers, each layer is several, and several ceramic rods are arranged at intervals along the thickness direction of the armor plate la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com