Planar capacitive high-pressure-resistant miniature pressure sensor and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the direction of fluid pressure measurement, instrument, and measurement force using capacitance change, can solve the problems of insufficient reliability, difficulty in meeting the application requirements of high pressure detection scenarios, and small pressure detection range, and achieves High sensitivity and high pressure resistance, improved sensor performance, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are combined with the specific Figure 1 to Figure 5 The present invention will be further described, but the present invention is not limited to the following examples.

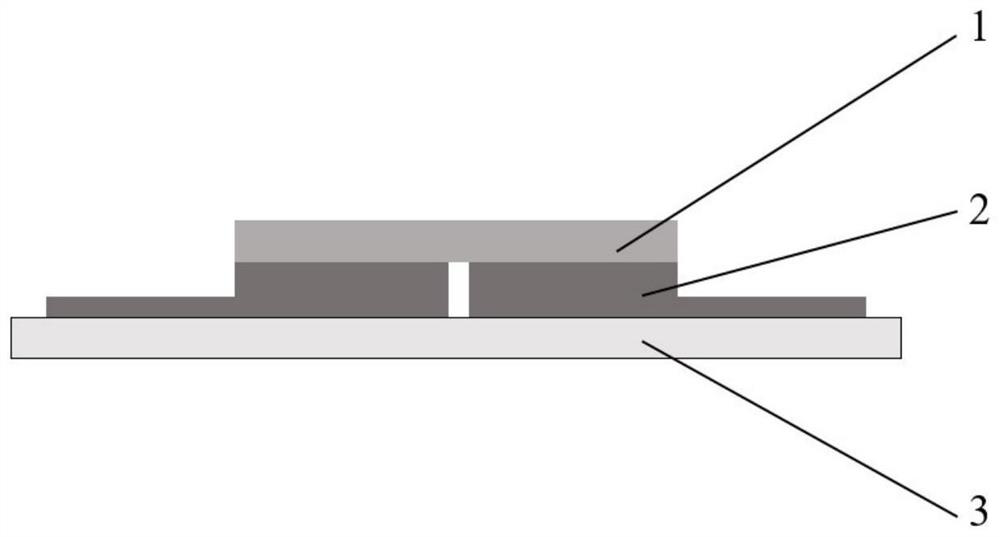

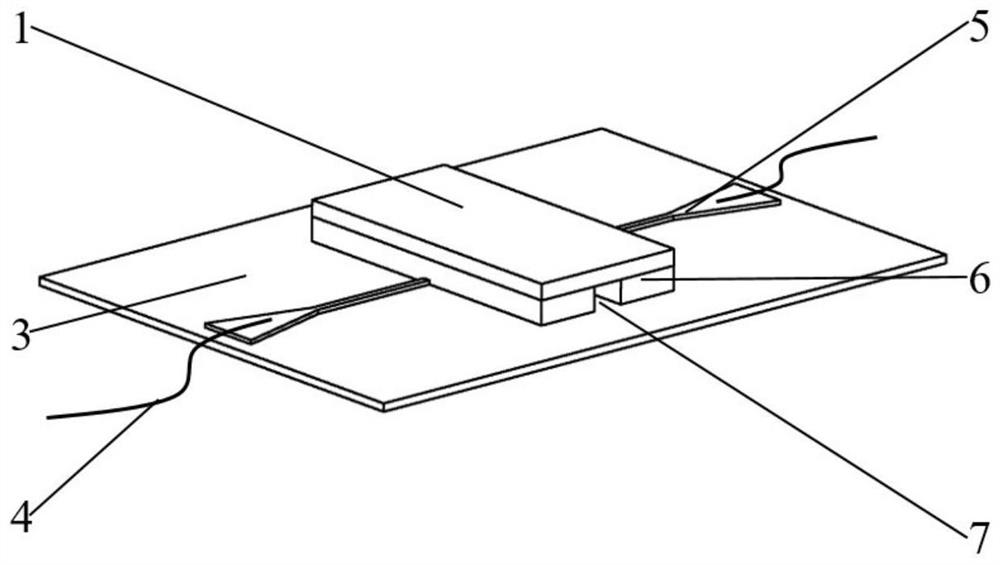

[0048] see figure 1 , figure 2 , in one embodiment, the present disclosure discloses a planar capacitive micro pressure sensor, characterized in that:

[0049] The sensor comprises: a medium layer (1), an electrode layer (2) and an insulating substrate (3);

[0050] The electrode layer (2) comprises a sensing electrode (6) with two parallel planes, and an air gap (7) between the two planes;

[0051] in,

[0052] When the sensing electrode (6) is formed, it is initially a whole body, and then an air gap (7) is formed through processing and a first sensing electrode and a second sensing electrode are formed;

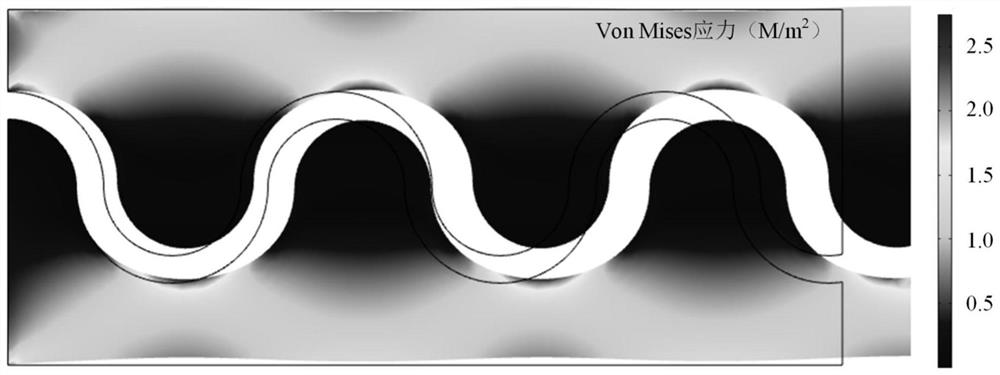

[0053] The air gap includes an S-shaped structure.

[0054] For the described embodiment, the working principle of the planar capacitive pressure sensor is based on the establ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com