A kind of liquefied natural gas bog recovery device and recovery method

A technology of liquefied natural gas and a recovery method, which is applied in the field of recovery devices for liquefied natural gas evaporated gas, can solve the problems of high energy consumption, narrow application range, and difficult secondary flash operation of the recovery process, and achieve types and quantities reduction, responsiveness Effects with a wide range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

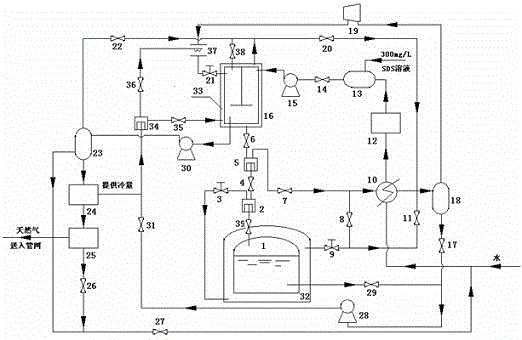

[0022] like figure 1 As shown, according to the accompanying drawings, this recovery method is: the device of the present invention consists of LNG storage tank 1, flow distributor 2,5,34; control valve 3,9,21; one-way valve 4,6,7 , 11, 14, 20, 22; two-way valve 8; heat exchange ice making device 10; grinder 12; liquid storage tank 13; water pump 15; hydrate reactor 16; one-way stop valve 17, 26, 27, 29 , 31, 35, 36; separation tank 18; BOG compressor 19; vertical three-phase separator 23; hydrate storage unit 24; hydrate decomposition unit 25; high-pressure pump 28; slurry pump 30; LNG storage tank insulation chamber 32; hydration reactor cooling chamber 33; mixing cooling unit 37; safety valve 38; pressure regulating valve 39; its recovery process mainly includes the following aspects:

[0023] 1: After the BOG in the LNG storage tank 1 exceeds a certain pressure, the gas passes through the pressure regulating valve 39 and then enters the first flow distributor 2 to be divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com