Fat-reducing fried fresh cheese and preparation method thereof

A frying and fresh technology, applied in the field of cheese processing, can solve the problems of not being suitable for consumers, single type of cheese, weakening the flavor of cheese, etc., and achieve the effect of increasing cheese production, smooth and delicate appearance, and enriching eating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

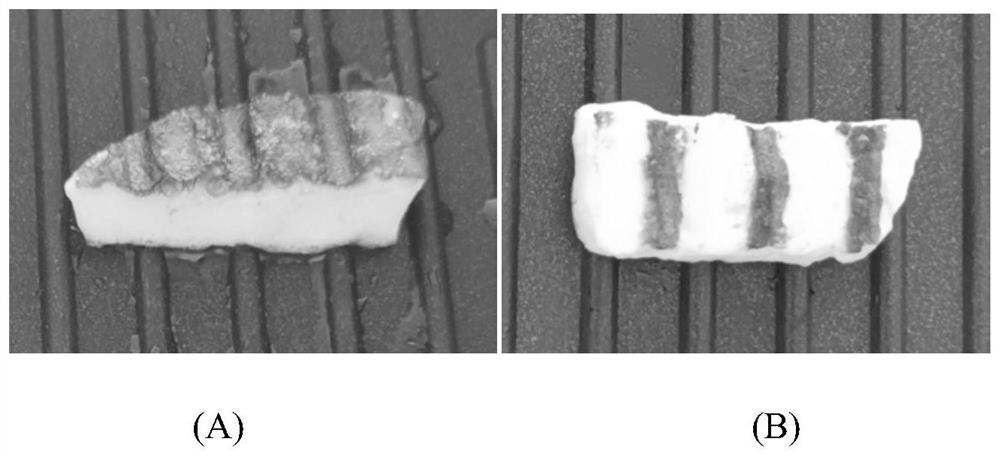

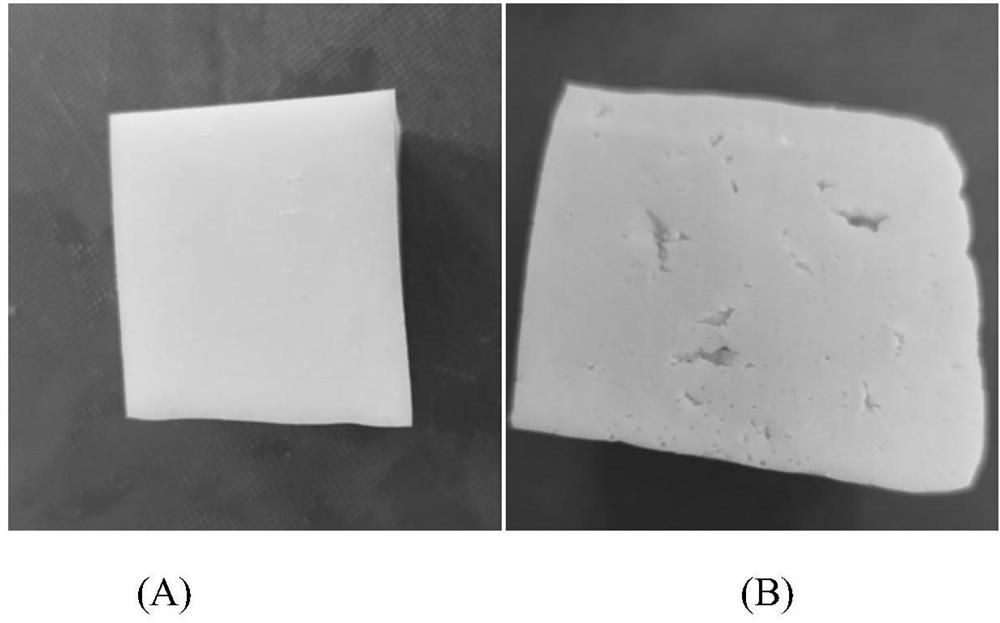

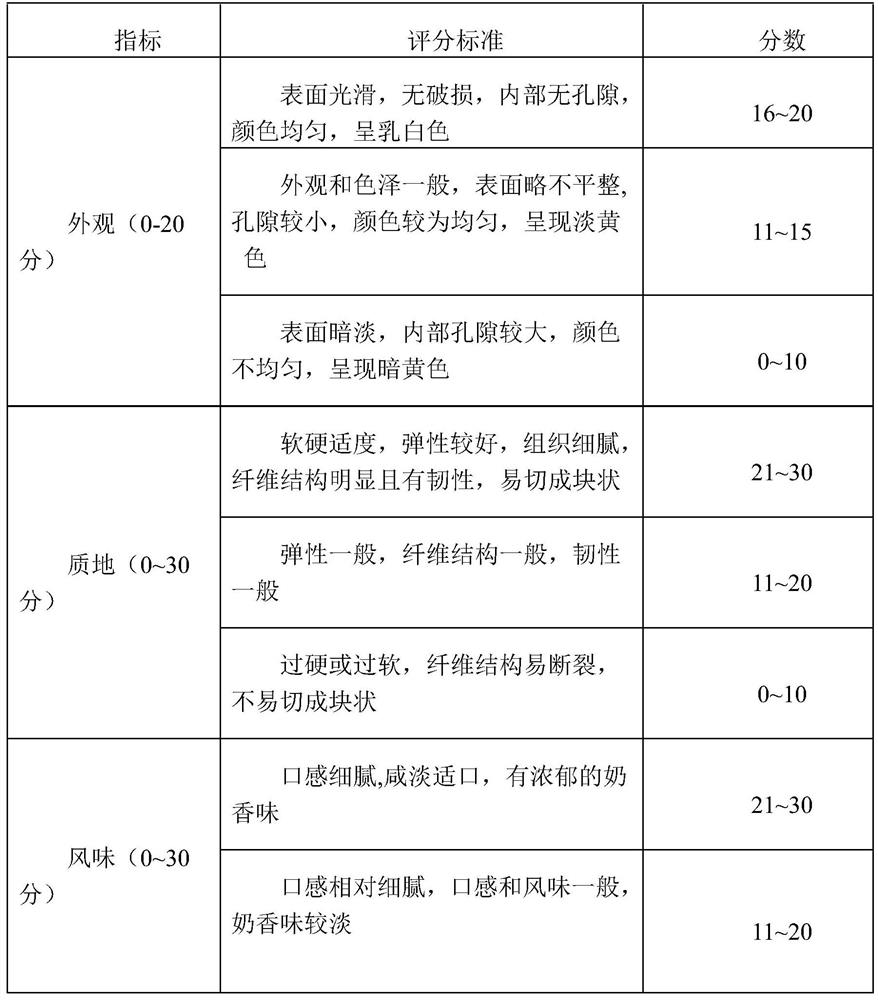

Image

Examples

Embodiment 1

[0050] A preparation method of fat-reduced grilled fresh cheese, comprising the following steps:

[0051] (1) After homogenizing the fresh cream, add it to the skim milk, and the homogenizing pressure is 4Mpa to prepare the reduced-fat milk.

[0052] (2) Blend the reduced-fat milk with a blender for 30 minutes. The fat content of reduced-fat milk is 2.4%.

[0053] (3) Pasteurizing the fat-reduced milk prepared in step 1 and cooling to 33° C. to obtain sterilized fat-reduced milk.

[0054] (4) Add citric acid to the sterilized fat-reduced milk obtained in step 2, adjust the pH to 6.5, then add 0.006% rennet, let the milk stand for 47 minutes, cut, let stand, and heat the whey for continuous discharge. Stir to collect the drained whey.

[0055] (5) Put the curd particles obtained in step 3 into a mold, press for 1.5 hours, and turn over 2 to 3 times during the period to obtain a molded cheese block.

[0056] (6) add 5% of heavy cream to the whey collected in step 4, and stir...

Embodiment 2

[0060] A preparation method of fat-reduced grilled fresh cheese, comprising the following steps:

[0061] (1) After homogenizing the fresh cream, add it to the skim milk, and the homogenizing pressure is 6Mpa to prepare the reduced-fat milk.

[0062] (2) Blend the reduced-fat milk with a blender for 60 minutes. The fat content of reduced-fat milk was 2.37%.

[0063] (3) Pasteurizing the fat-reduced milk prepared in step 1 and cooling to 33° C. to obtain sterilized fat-reduced milk.

[0064] (4) Add citric acid to the sterilized fat-reduced milk obtained in step 2, adjust pH to 6.3, then add 0.006% rennet, curd time 45min, cut, let stand, heat to drain whey, and stir continuously during the period, The drained whey was collected.

[0065] (5) Put the curd particles obtained in step 3 into a mold, press for 1.5 hours, and turn over 2 to 3 times during the period to obtain a molded cheese block.

[0066] (6) adding 4% of the heavy cream to the whey collected in step 4, and st...

Embodiment 3

[0070] A preparation method of fat-reduced grilled fresh cheese, comprising the following steps:

[0071] (1) After homogenizing the fresh cream, add it to the skim milk, and the homogenizing pressure is 8Mpa to prepare the reduced-fat milk.

[0072] (2) Blend the reduced-fat milk with a blender for 45 minutes. The fat content of reduced-fat milk is 2.45%.

[0073] (3) Pasteurizing the fat-reduced milk prepared in step 1 and cooling to 33° C. to obtain sterilized fat-reduced milk.

[0074] (4) Add citric acid to the sterilized fat-reduced milk obtained in step 2, adjust the pH to 6.3, then add 0.004% rennet, the curdling time is 48min, cut, let stand, heat the whey, and stir continuously during the period, The drained whey was collected.

[0075] (5) Put the curd particles obtained in step 3 into a mold, press for 1.5 hours, and turn over 2 to 3 times during the period to obtain a molded cheese block.

[0076] (6) add 5% of heavy cream to the whey collected in step 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com