Soybean oil skin production equipment and technology

A production equipment and a technology for soybean oil skins, applied in the field of soybean product production equipment, can solve the problems of small oil skin formation area, multiple manpower, single form, etc., and achieve the effects of solving harsh installation conditions, reducing adhesion waste, and saving occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

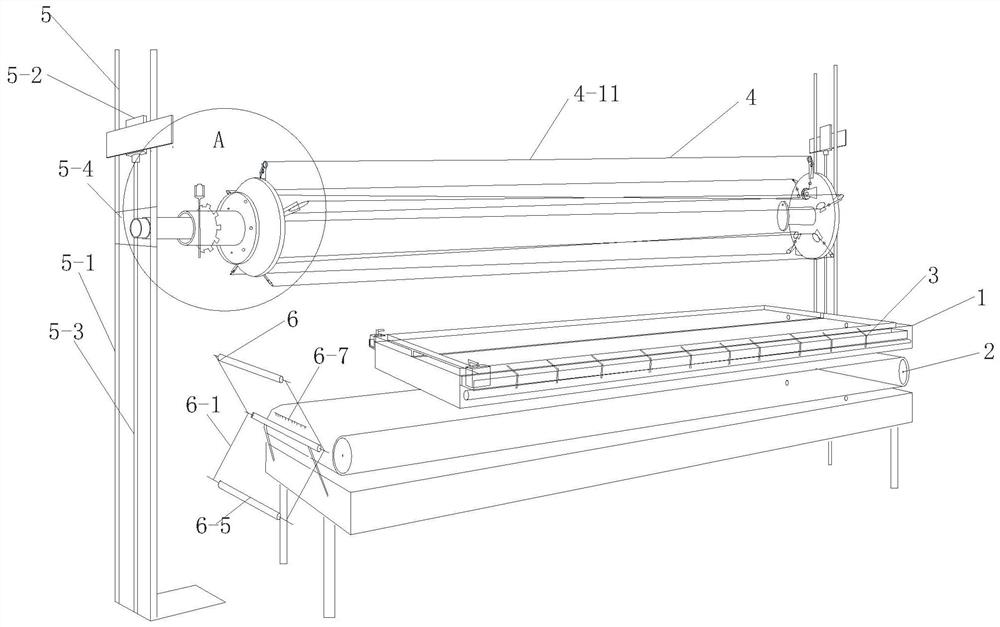

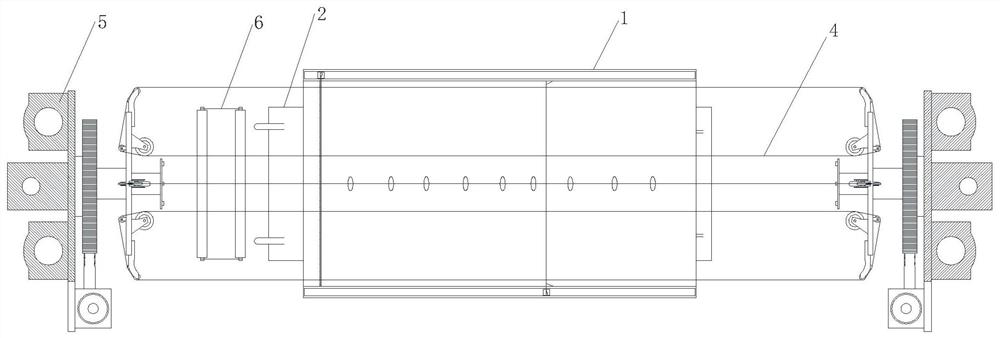

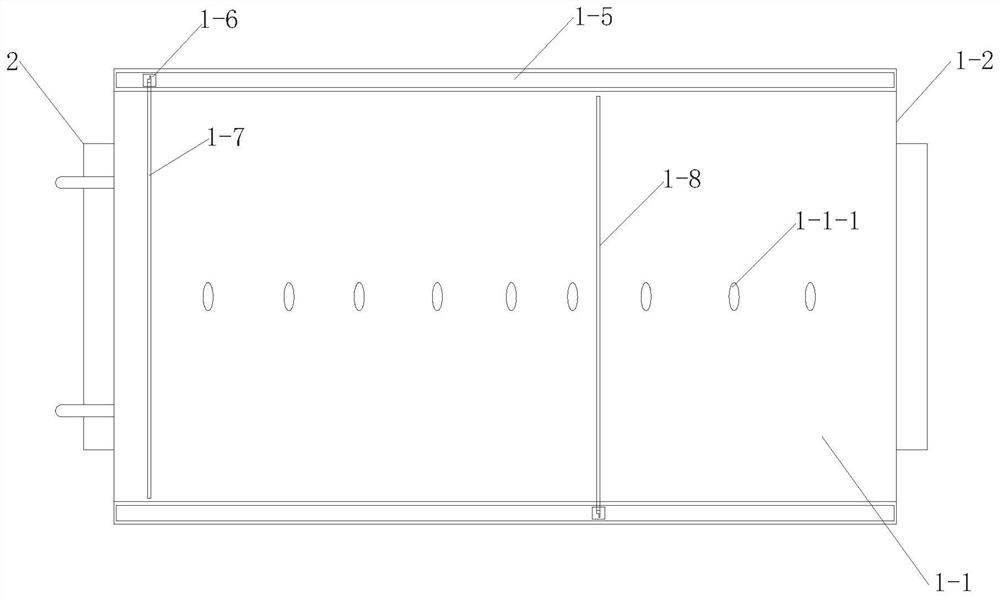

[0059] A soybean oil husk production equipment, comprising a controller, a pulp holding tank, a drying transmission mechanism is arranged below the pulp holding tank, a pulp distribution mechanism is arranged on one side of the pulp holding tank; A lifting mechanism is provided on both sides of the pulp holding tank; the lifting mechanism is connected with the lifting mechanism; the rear end of the drying transmission mechanism is provided with a winding mechanism; the controller is respectively connected with the pulp holding tank and the drying transmission mechanism , The pulping mechanism, the lifting mechanism, the lifting mechanism and the winding mechanism are controlled and connected.

[0060] The slurry tank includes a bottom plate and a detachable enclosure plate arranged on the bottom plate; the left side enclosure plate and the right side enclosure plate of the slurry tank are provided with slide rails, and the slide rails are slidably connected with a downward pres...

Embodiment 2

[0068] A process for producing soybean oil husks, using a kind of soybean oil hull production equipment described in Embodiment 1, comprises the following steps:

[0069] (1) The lifting motor works, the receiving plate moves from top to bottom to the bottom along the screw rod, and at the same time the rotating receiving plate rotates, the bow-shaped wire lifting bracket and the corresponding lifting wire enter the pulp tank, and are embedded in the lobe shape of the wire planting gap. Inside the line jam;

[0070] (2) The controller controls the opening of the steam valve, and at the same time, the pulp distribution quantitative bucket distributes pulp to the pulp holding tank; after the pulp distribution is completed, the homogenizer performs homogenization; after the homogenization is completed, let it stand for a set time;

[0071] (3) When the time is up, the edge patrol machine moves back and forth while the steam valve is closed, the air valve is opened, the rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com