Elastic folding stirring paddle for strengthening phosphorite acidolysis

A stirring paddle, acid hydrolysis technology, applied in mixers with rotating stirring devices, dissolution, chemical instruments and methods, etc., can solve the problems of large centrifugal force, radial solid concentration difference, high solid content, and achieve strong cutting effect, The effect of increasing the degree of turbulence and increasing the degree of chaotic mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

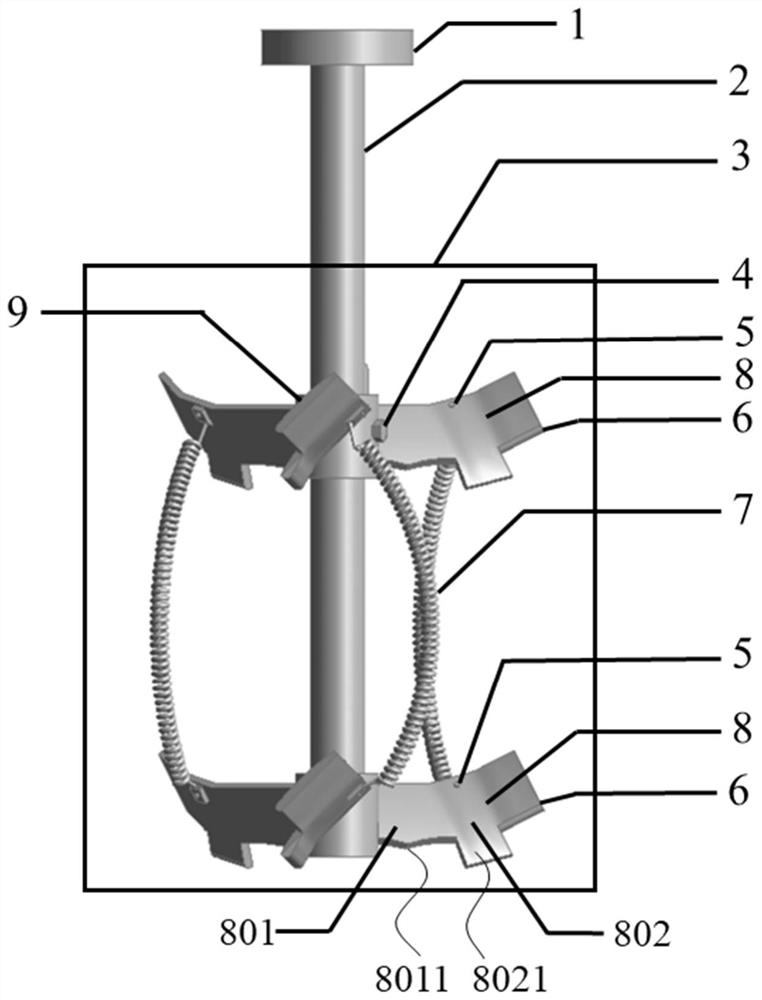

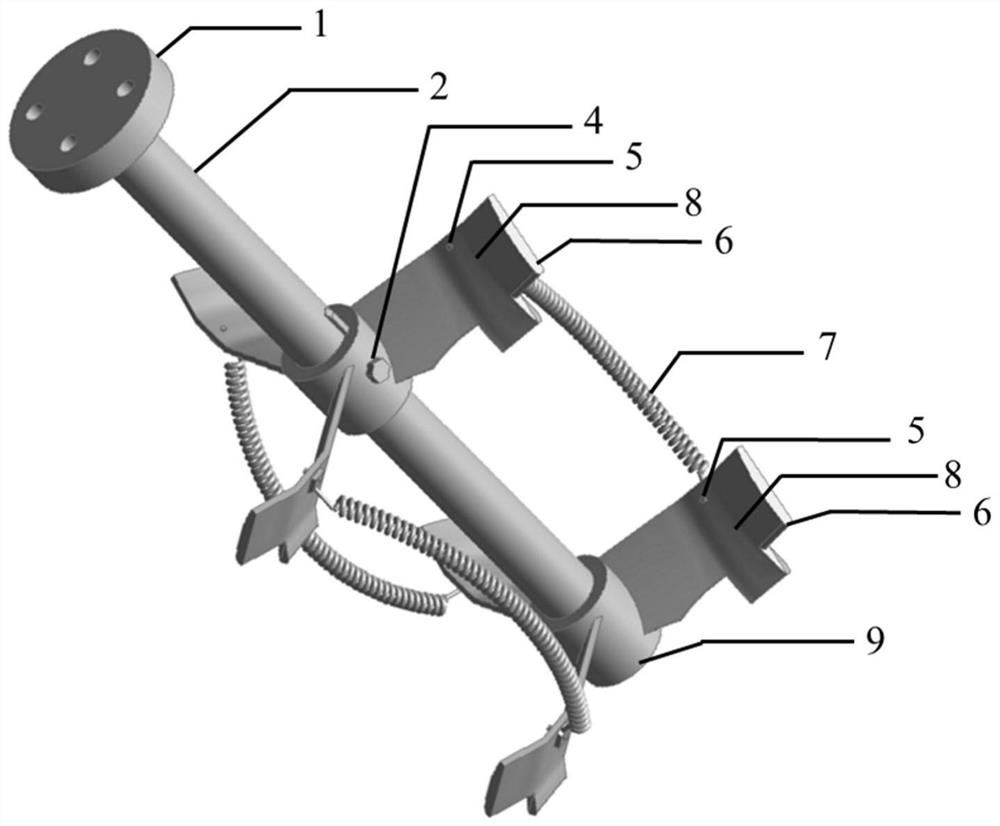

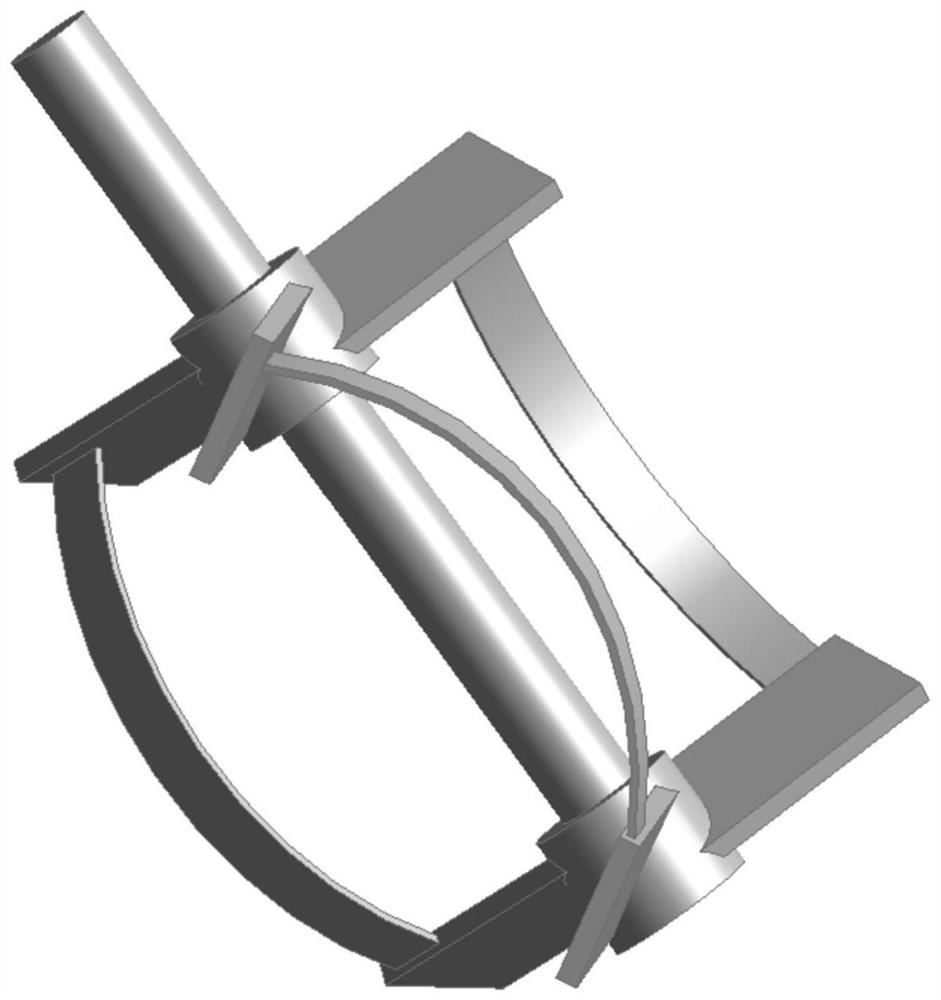

[0044] An elastic folding stirring paddle for strengthening the acid hydrolysis of phosphate rock, is characterized in that: comprising a holder 1, a stirring shaft 2, two groups of rigid stirring paddles 6 and a group of coil springs 7;

[0045] The fixing base 1 is connected with the stirring shaft 2 as a whole; the fixing base 1 is connected with an external motor to drive the stirring shaft 2 to rotate; in the embodiment, the fixing base 1 is a cylindrical structure with four circular holes inside ; The fixing base 1 is connected with the stirring shaft 2 as a whole; the fixing base 1 can be connected with an external motor through screws;

[0046]Two groups of rigid stirring paddles 6 are connected around the stirring shaft 2; a group of rigid stirring paddles 6 includes several rigid blades 8 that are radially connected around the stirring shaft 2; each rigid blade 8 includes three parts, denoted as connecting parts 801 , a first bending part 802 and a second bending par...

Embodiment 2

[0052] The main structure of this embodiment is the same as that of Embodiment 1, and further, the length ratio of the connecting portion 801 , the first bending portion 802 and the second bending portion 803 is 18:7:7. The height to length ratio of the connecting portion 801 is 1.2:14. The height to length ratio of the connecting portion 802 is 1.2:7. The height and length ratio of the connecting portion 803 is 1.1:7. The above "length" is measured from the end close to the stirring shaft 2 and ends at the end far from the stirring shaft 2 . The above "height" is measured from the end close to the fixing base 1 and ends at the end far from the fixing base 1 .

Embodiment 3

[0054] The main structure of this embodiment is the same as that of Embodiment 1 or 2, and further, a set of rigid stirring paddles 6 includes a shaft sleeve 9; the rigid blade 8 is connected to the stirring shaft 2 through the shaft sleeve 9;

[0055] The shaft sleeve 9 is sleeved on the stirring shaft 2, and each rigid blade 8 is connected to the shaft sleeve 9 obliquely; during stirring, the water-facing surface of the connecting portion 801 of the rigid The downstream surface is inclined downward; the angle between the lower end of the upstream surface of the connection portion 801 of the rigid blade 8 and the horizontal plane is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com