Deacidification circulation system and deacidification process

A circulation system and deacidification technology, applied in the field of deacidification, can solve the problems of low efficiency, poor deacidification effect, uneven deacidification reaction, etc., and achieve high deacidification efficiency and good deacidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

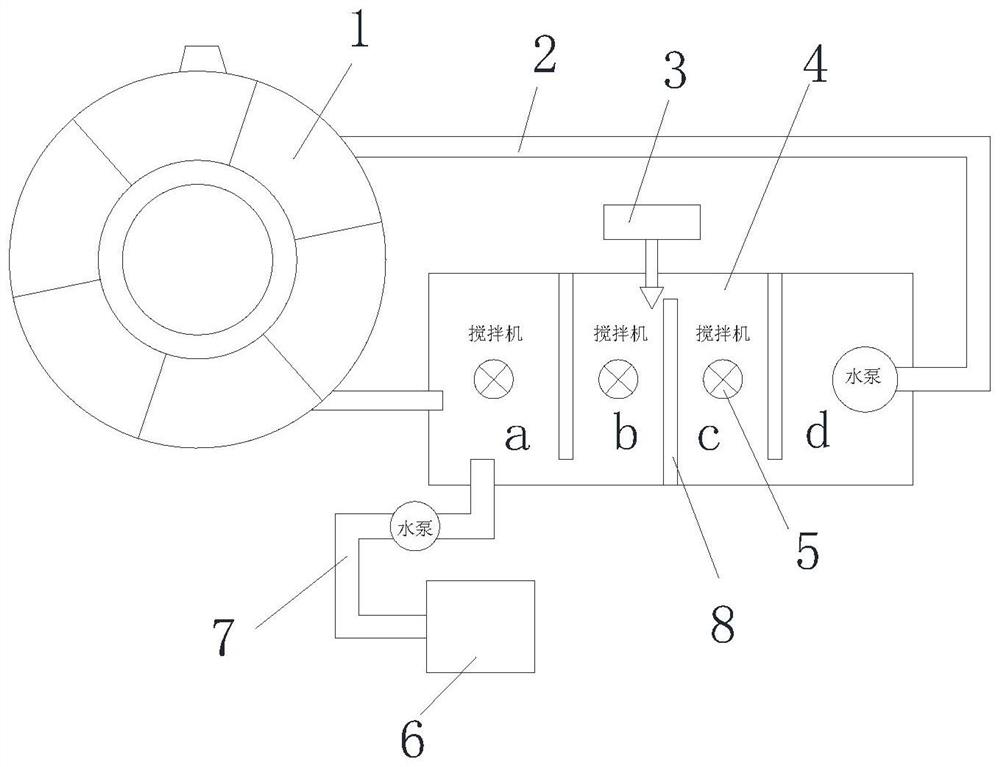

[0033] like figure 1 As shown, the present invention provides a deacidification circulation system, which includes a control device and a control system connected with a deacidification tower 1, a reaction tank 4 and a filter press 6, and the reaction tank 4 is used for deacidification through the set lye input pipeline 2. The tower 1 provides alkaline liquid, and the reaction tank 4 is provided with a feeding device 3 to provide calcium hydroxide alkaline substance for the reaction tank 4. A number of adjacent partition plates 8 are arranged inside the reaction tank 4. The partition plates 8 divide the reaction tank 4 into several sub-pools that are connected to each other and are arranged in sequence. The openings of the adjacent partition plates 8 The staggered arrangement allows the lye in it to circulate and flow around, wherein a mixer 5 is arranged in the middle of the front sub-pool, and the sub-pool at the rear is connected to the input pipeline 2, and the input pipel...

Embodiment 2

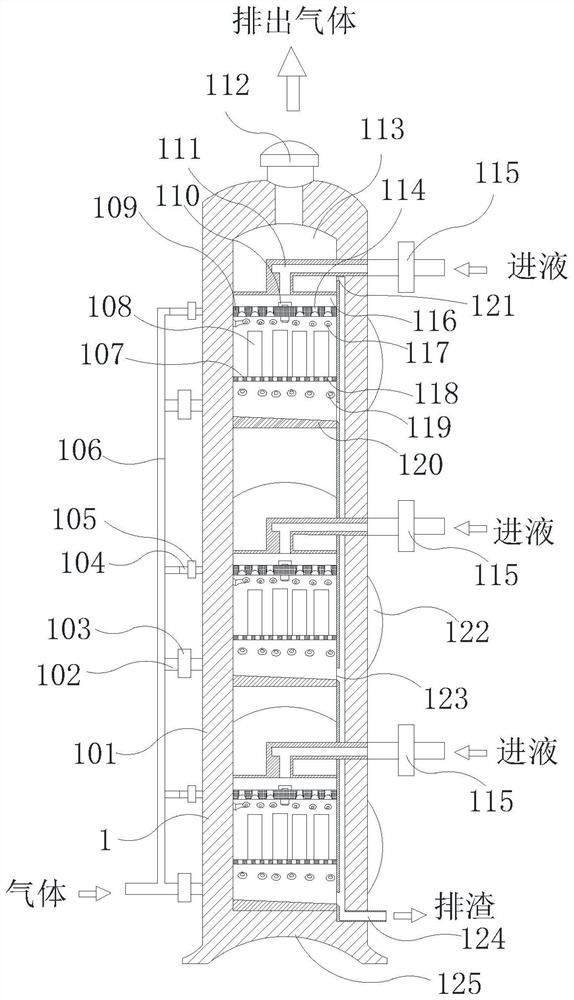

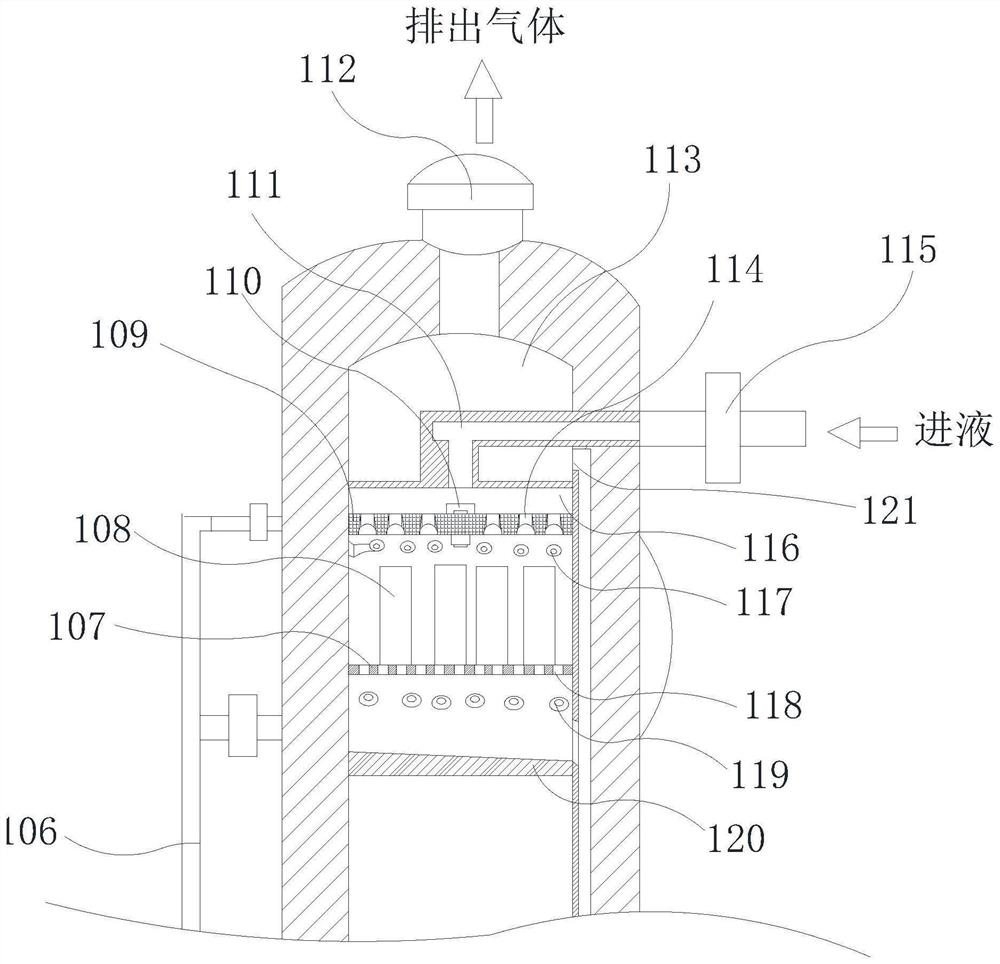

[0047] This embodiment is further improved on the basis of Embodiment 1. The difference is that: the deacidification cycle system provided in this embodiment is designed to allow the material 108 deacidified by the alkali solution to be quickly dried and the surface of the material 108 to be clean. , the inner cavity 113 is provided with a plurality of second air nozzles 117 on the side wall of the lower side of the diffuser 109. The second air nozzles 117 are connected with the second branch air intake pipe 104 through the air pipe, and the second branch air intake pipe 104 is provided with a control The second valve 105 connected to the device is connected to the control device, and the second air nozzle 117 is set in the downward direction and facing the material 108. Before the material 108 is taken out, use the control device to open the second valve 105 and perform 5-10 on the material 108. minutes of blowing.

[0048] In the deacidification process, a preferred technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com