Device and method for dedusting and purifying tail gas of glass melting furnace

A tail gas dedusting and kiln technology, which is applied in the direction of furnace control devices, chemical instruments and methods, separation methods, etc., to achieve the effect of avoiding filter bag sticking, avoiding sticky bags, and simple and reliable control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In order to make the present invention clearer, a device and method for dust removal and purification of glass melting furnace tail gas according to the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not used for limit the invention.

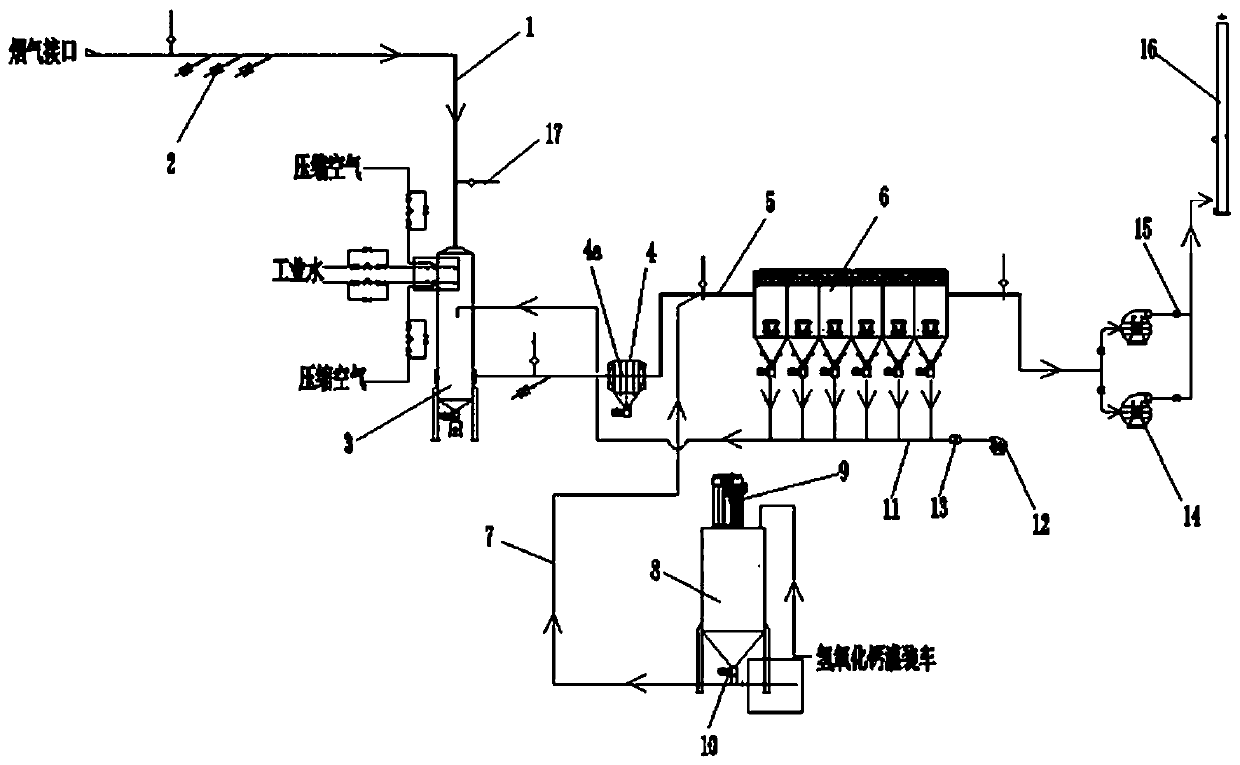

[0030] see figure 1 , a device for dedusting and purifying the tail gas of a glass melting furnace, comprising a negative pressure main pipe 1 connected to a flue gas interface, characterized in that:

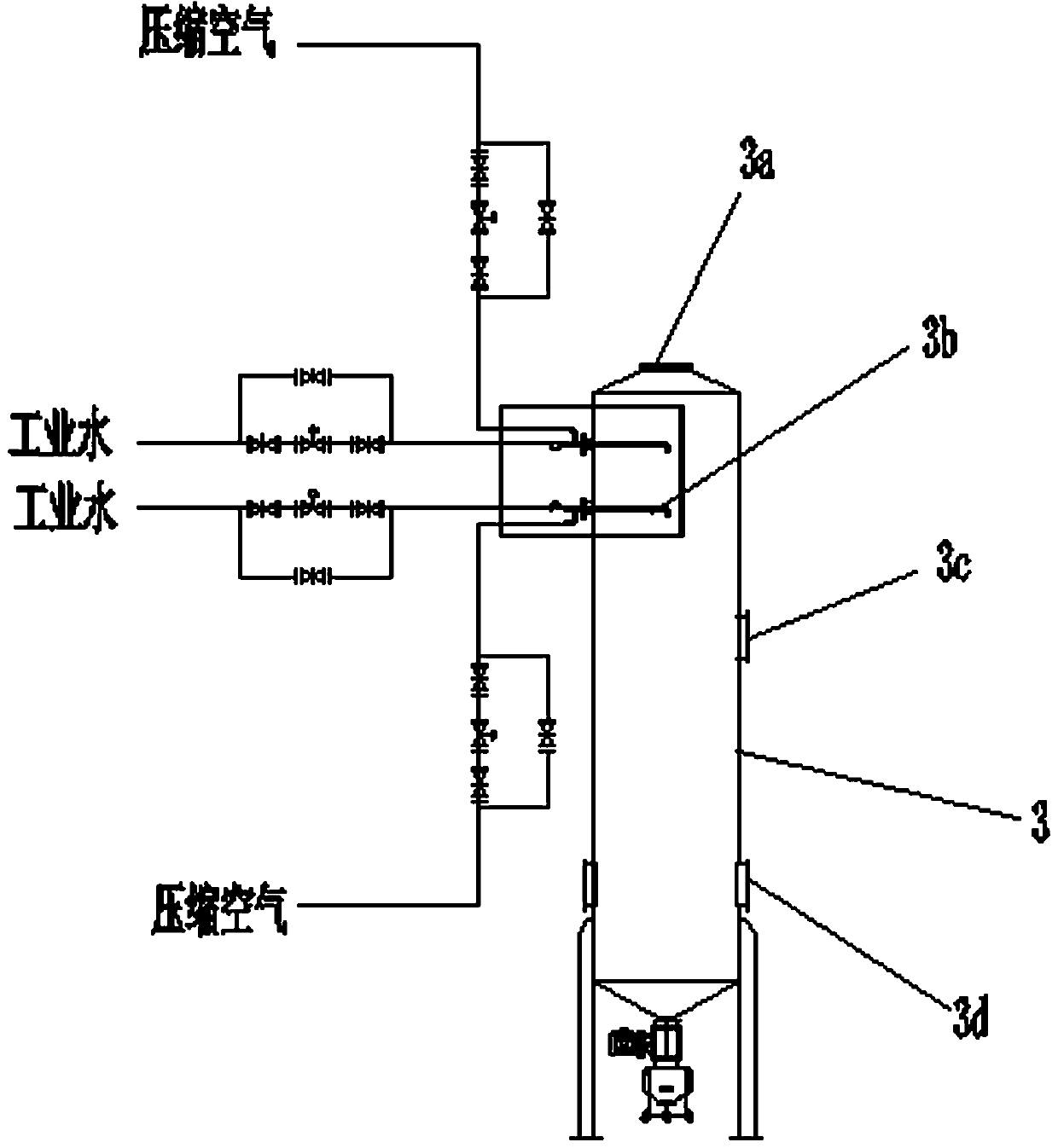

[0031] see figure 1 and figure 2 The negative pressure main pipe 1 is provided with three electric supplementary air valves 2, the negative pressure main pipe 1 is connected with the top inlet 3a of a spray cooling tower 3, the upper part of the spray cooling tower 3 is provided with a group of spray guns 3b connected with industrial water, and the middle part is provided with There is a recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com