Production equipment of environment-friendly low-cost magnesian dry material

A production equipment and low-cost technology, which is applied in the field of production equipment for environmentally friendly low-cost magnesium dry materials, can solve problems such as the quality reduction of magnesium dry materials, the impact on workers' health, and the treatment of harmful gases, so as to speed up the production of raw materials. Effects of mixing, manpower saving and safety increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

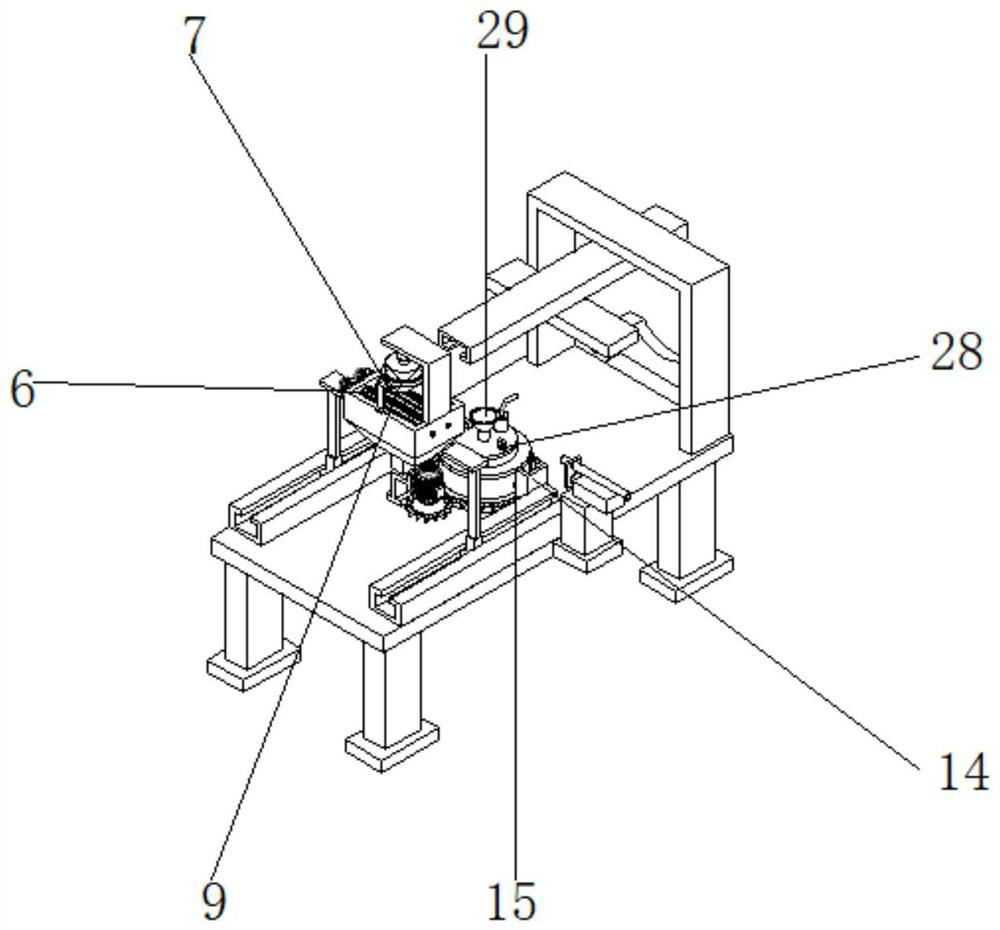

[0031] refer to Figure 1-4 , Environmentally friendly low-cost magnesium dry material and its production equipment, including workbench 1, electric slide rails 2 are installed on both sides of the top of workbench 1, and electric slide rails 2 are slidably installed on the inner wall of the electric slide rails. A support rod 3 is fixed, and a crushing box 4 is installed between the supporting rods 3. A discharge pipe 5 is connected to the bottom of the crushing box 4, and a first crushing roller 6 and a second crushing roller 7 are rotated and installed inside the crushing box 4. A pulverizing roller 6 and a second pulverizing roller 7 are connected with a drive motor 8 through a coupling;

[0032] Before mixing and manufacturing magnesia and other large fixed raw materials, put them into the mashing shell 9 first, and use the continuous impact of the cone-shaped pounding table 12 to reduce the mashing of the particles and then discharge them from the bottom, so that the par...

Embodiment 2

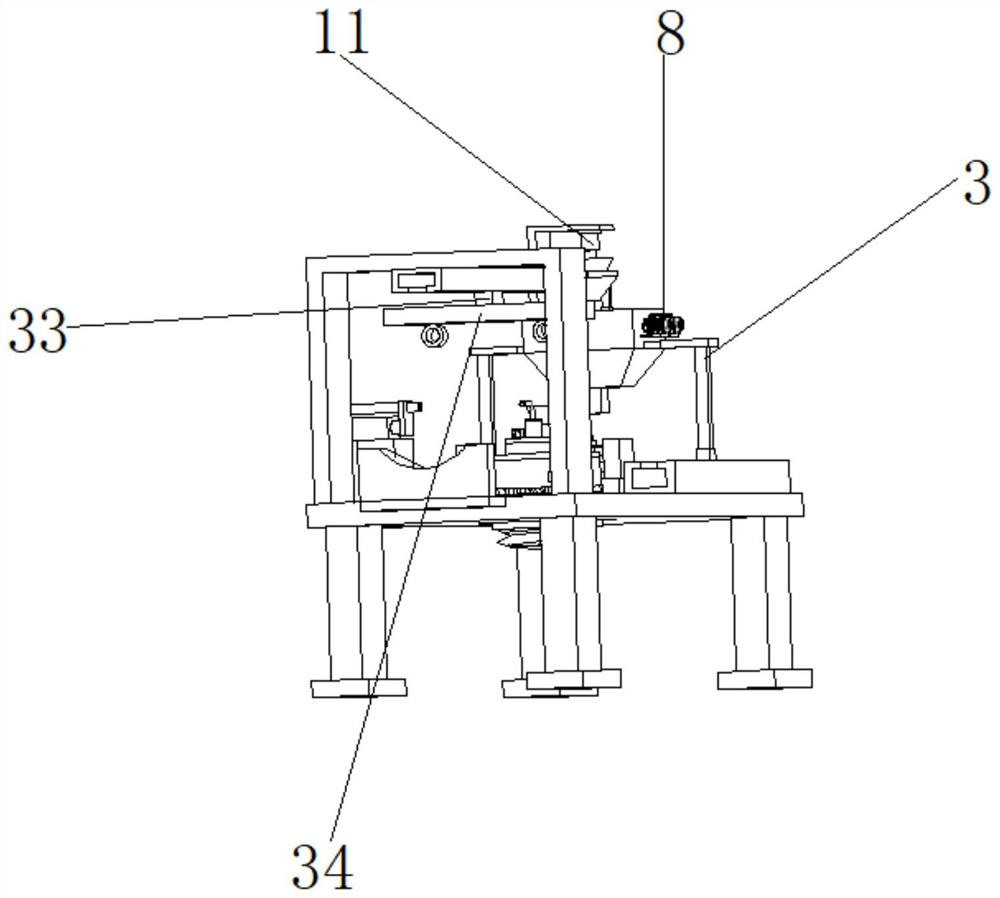

[0040] refer to Figure 2-6, Environmentally friendly low-cost magnesium dry material and its production equipment, including workbench 1, electric slide rails 2 are installed on both sides of the top of workbench 1, and electric slide rails 2 are slidably installed on the inner wall of the electric slide rails. A support rod 3 is fixed, and a crushing box 4 is installed between the supporting rods 3. A discharge pipe 5 is connected to the bottom of the crushing box 4, and a first crushing roller 6 and a second crushing roller 7 are rotated and installed inside the crushing box 4. A pulverizing roller 6 and a second pulverizing roller 7 are connected with a drive motor 8 through a coupling;

[0041] The first pulverizing roller 6 and the second pulverizing roller 7 mesh with each other, and the rotation directions of the first pulverizing roller 6 and the second pulverizing roller 7 are opposite. 9 is adapted to the cone pounding table 12;

[0042] A mashing shell 9 is arran...

Embodiment 3

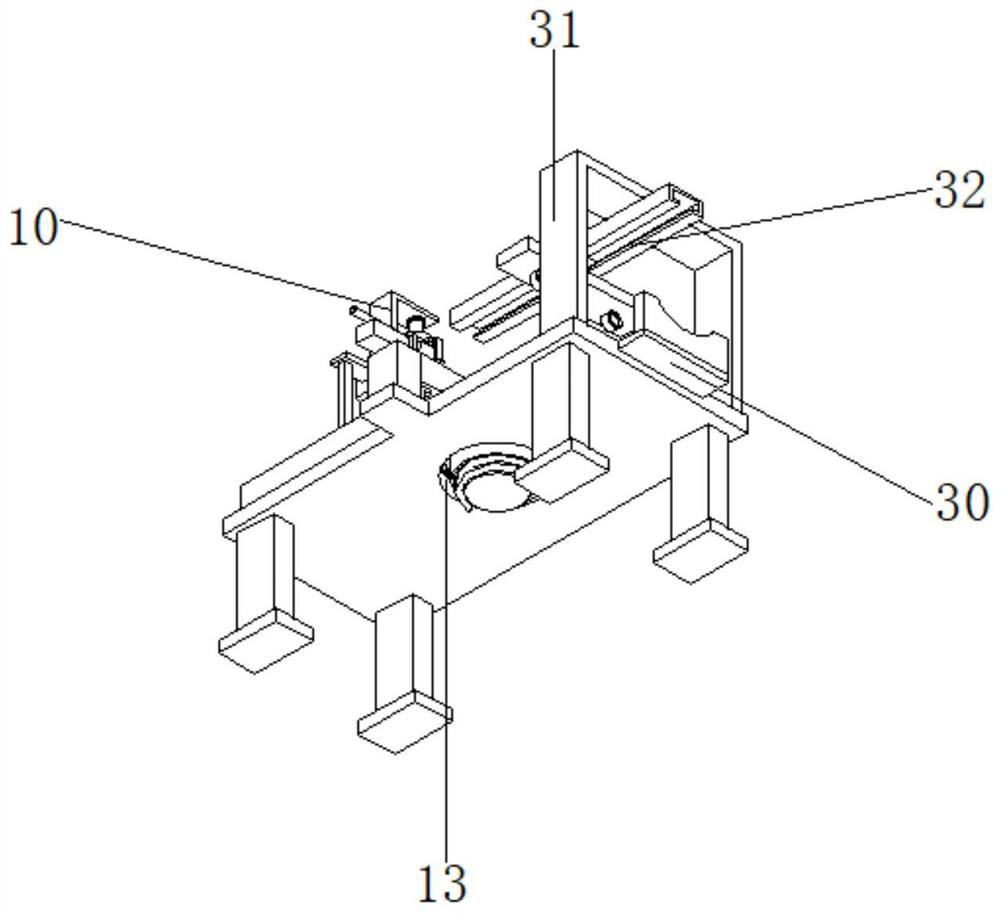

[0049] refer to Figure 4-6 , Environmentally friendly low-cost magnesium dry material production equipment, including workbench 1, electric slide rails 2 are installed on both sides of the top of workbench 1, and electric slide rails 2 are slidably installed on the inner wall of the electric slide rails. A support rod 3 is fixed, and a crushing box 4 is installed between the supporting rods 3. A discharge pipe 5 is connected to the bottom of the crushing box 4, and a first crushing roller 6 and a second crushing roller 7 are rotated and installed inside the crushing box 4. A pulverizing roller 6 and a second pulverizing roller 7 are connected with a drive motor 8 through a coupling;

[0050] The first pulverizing roller 6 and the second pulverizing roller 7 mesh with each other, and the rotation directions of the first pulverizing roller 6 and the second pulverizing roller 7 are opposite. 9 is adapted to the cone pounding table 12;

[0051] A mashing shell 9 is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com