High-molecular chemical coal-rock mass reinforcing agent for coal mine and injection method of high-molecular chemical coal-rock mass reinforcing agent

A technology of reinforcing agent and polymer, which is applied in the field of coal and rock mass reinforcement, can solve the problems of inconvenient segment grouting and inconvenient internal air discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

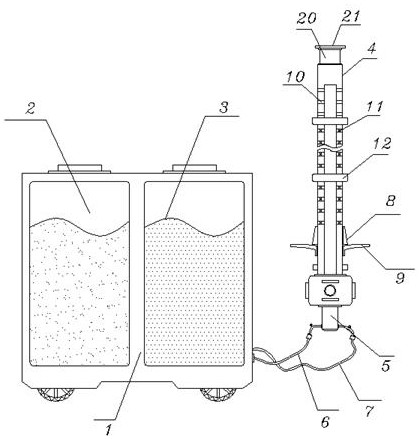

[0040] see Figure 1-4 , the injection method includes the following steps:

[0041] S1: First move the storage truck 1 to the working area, inject components A and B into the material storage cavity 2 of material A and material storage cavity 3 of material B respectively, and drill the rock wall of the working area, and then Insert the injection rod 4 into the drilled tunnel, and the top plate 21 is placed on the inner wall of the tunnel;

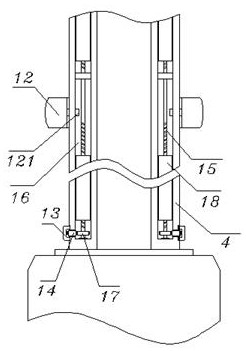

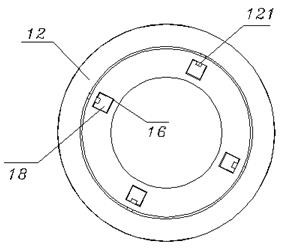

[0042] S2: Before injection, first rotate the movable ring gear 13, the movable ring gear 13 drives the screw 15 to rotate through the intermediate gear 14 and the guide gear sleeve 17, and then pushes the sealing strip 18 to move in the gas transmission groove 16, and the gas passes through the gas transmission pipe. 121 is input into the sealing airbag ring 12, so that the sealing airbag ring 12 expands and contacts the inner wall of the hole, and the injection rod 4 is fixed by the sealing airbag ring 12 in conjunction with the slurry ...

Embodiment 2

[0054] see figure 1 and Figure 5-8 , the top of the injection rod 4 is embedded with a motor 19, and the output end of the motor 19 is connected with a separation column 20, and the bearing of the separation column 20 is installed on the top of the injection rod 4, and the top bearing of the separation column 20 is connected with the top plate 21, The output shaft of the motor 19 is meshed with a movable tooth sleeve 25 through the toothed disc 22, and the movable tooth sleeve 25 is sleeved on the guide post 24, and the guide post 24 bearing is installed in the air extraction slot 23, and the air extraction slot 23 is opened. Inside the injection rod 4, the middle position of the guide post 24 is connected with another separation post 20 through the first bevel gear transmission assembly 241, and the separation post 20 is installed on the outer side of the middle of the injection rod 4 through the transverse seal and the guide post 24 A fan assembly 27 is connected to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com