Sodium polyacrylate splash-proof preparation and preparation method thereof

A technology of sodium polyacrylate and anti-splashing agent, which is applied in the field of sanitary products, can solve the problems of slow disintegration speed of anti-splashing preparations, and achieve the effect of optimizing toilet experience and good toilet experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

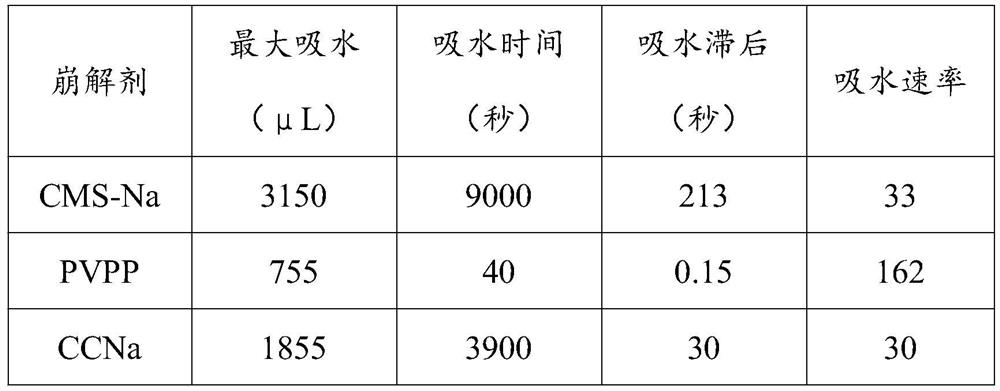

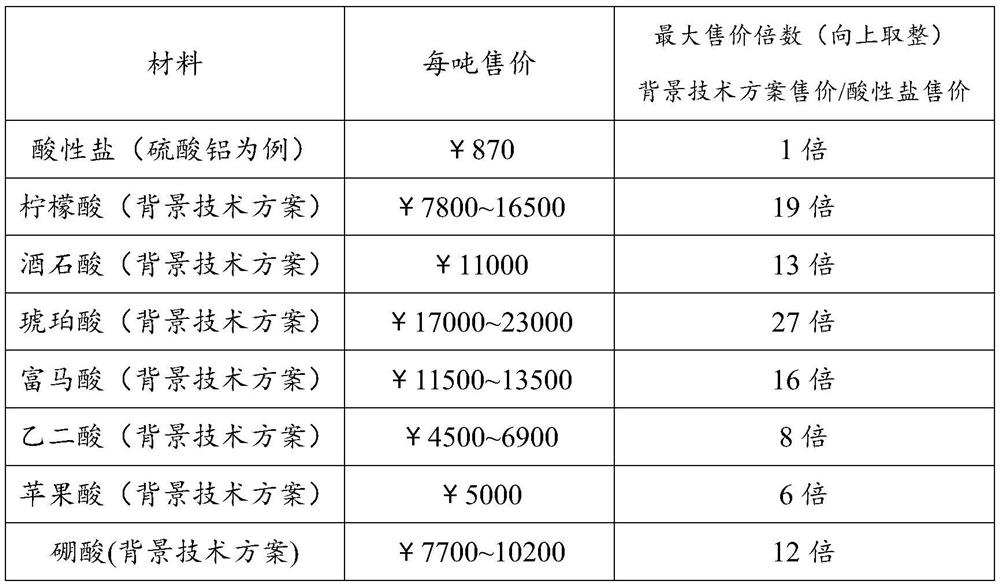

Method used

Image

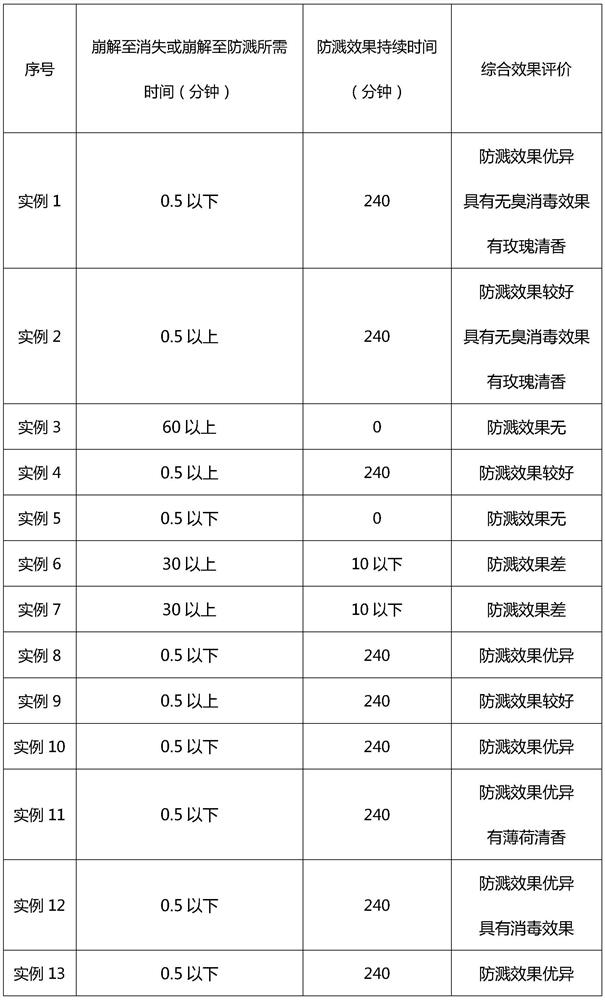

Examples

preparation example Construction

[0091] The preparation method of the sodium polyacrylate splash-proof preparation of the present invention is obtained by adopting the mainstream tableting production process and molding, which is to use a certain process and equipment to shape the product, and the molded product is not necessarily in the form of a sheet, "tablet" The term is the industry name for raw material molding. For example, the specific tableting manufacturing process may be wet granulation and dry tableting, dry heavy pressing and rolling, non-aqueous granulation and tableting, powder direct tableting and other manufacturing processes.

[0092] Among them, wet granulation and dry tableting method is the most widely used production process, specifically mixing the raw materials first, then adding a binder (the patent wet process adopts 5% anhydrous povidone K30 in the raw powder powder) ethanol solution), the surface of the raw material powder will be wetted by the binder to generate adhesive force, an...

Embodiment 1

[0097] This embodiment provides a sodium polyacrylate splash-proof preparation, which is composed of the following components in parts by weight: 10 parts of splash-proof agent, 10 parts of disintegrating agent, 30 parts of acid agent, 30 parts of alkali agent, and 5 parts of thickener , 3 parts of fragrance, 4 parts of disinfectant, 3 parts of deodorant, 5 parts of accessories. Specifically, the anti-splash agent is sodium polyacrylate, the disintegrating agent is cross-linked polyvinylpyrrolidone, the acid agent is aluminum sulfate, the alkali agent is sodium bicarbonate, the thickening agent is xanthan gum, the fragrance agent is rose essential oil, and the disinfectant is selected. Povidone-iodine is used, thyme essential oil is used for deodorant, and mannitol is used as auxiliary material.

[0098] The preparation method of the sodium polyacrylate splash-proof preparation includes the following steps: weighing each raw material according to the proportion, pouring the ra...

Embodiment 2

[0100] This embodiment provides a sodium polyacrylate splash-proof preparation, which is composed of the following components in parts by weight: 10 parts of splash-proof agent, 10 parts of disintegrating agent, 30 parts of acid agent, 30 parts of alkali agent, and 5 parts of thickener , 3 parts of fragrance, 4 parts of disinfectant, 3 parts of deodorant, 5 parts of accessories. Specifically, the anti-splash agent is sodium polyacrylate, the disintegrating agent is sodium carboxymethyl starch, the acid agent is aluminum sulfate, the alkali agent is sodium bicarbonate, the thickening agent is xanthan gum, the fragrance agent is rose essential oil, and the disinfectant is selected. Povidone-iodine is used, thyme essential oil is used for deodorant, and mannitol is used as auxiliary material.

[0101] The preparation method of the sodium polyacrylate splash-proof preparation includes the following steps: weighing each raw material according to the proportion, pouring the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com