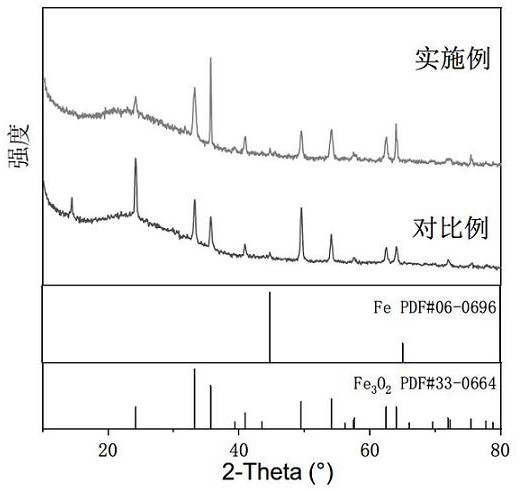

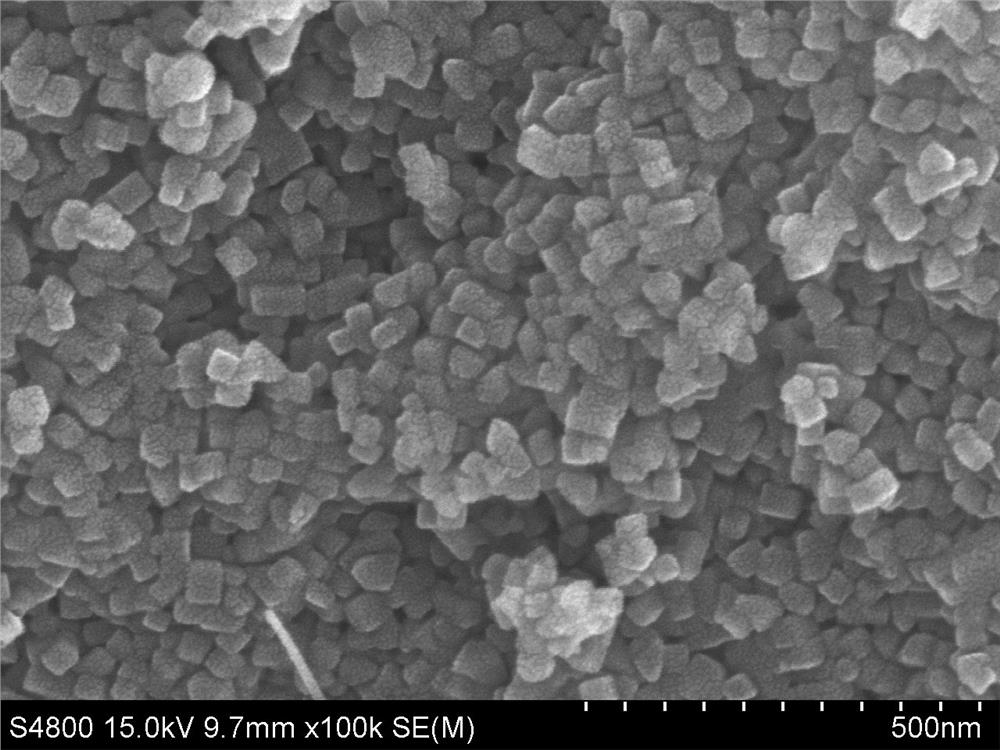

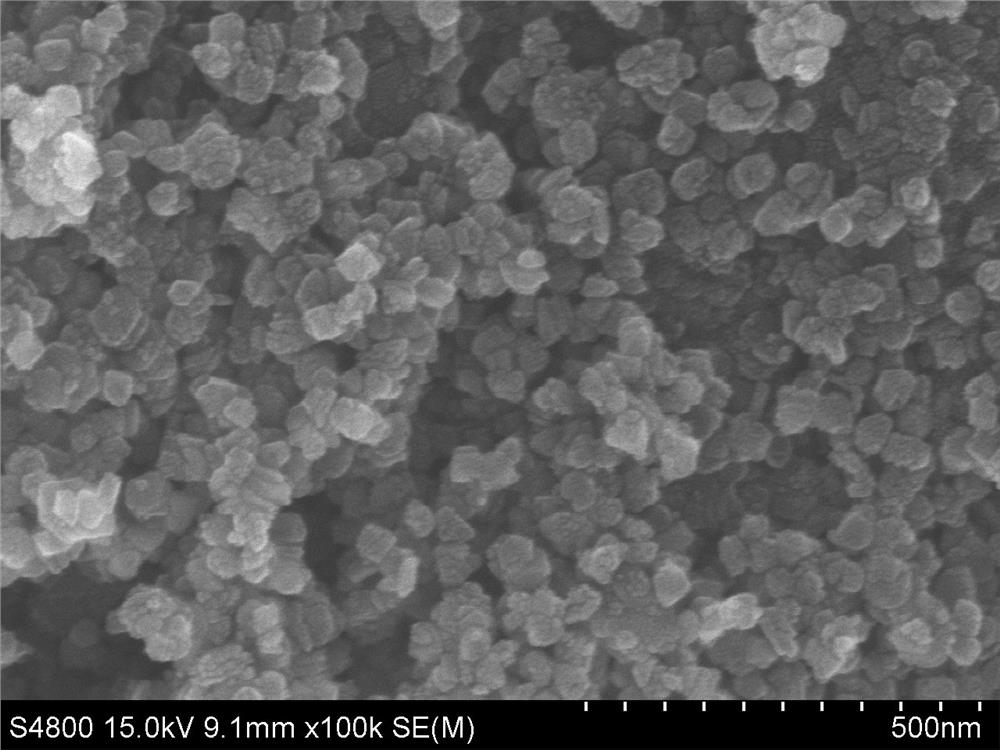

Deformed cubic Fe2O3/Fe compound and preparation method thereof

A composite, cube technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of poor electrical conductivity, high cost, small electrochemical active area, etc., and achieve the effect of excellent electrocatalytic oxygen evolution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Example: Weigh or measure 10 milliliters of octadecenoic acid, 1 gram of sodium hydroxide, and 10 milliliters of alcohol, add them to a beaker, and stir to form a uniform and transparent solution at room temperature; weigh 0.7 grams of acetylacetone Iron, completely dissolved in 20 ml of deionized water, the solution is a red solution, add it to the above solution, mix and stir for 1 hour, the solution is dark red, add the solution to the lining of a stainless steel autoclave with a capacity of 100 ml, The stainless steel autoclave was sealed and heated to 180 degrees, kept for 10 hours and then cooled naturally, and the red precursor was obtained after centrifugal cleaning with alcohol and deionized water for three times; Under the action of hydrogen and argon gas, the temperature was raised to 350 degrees Celsius at a heating rate of 2 degrees Celsius per minute. After holding for 2 hours, it was cooled to room temperature with the tube furnace; A three-electrode syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com