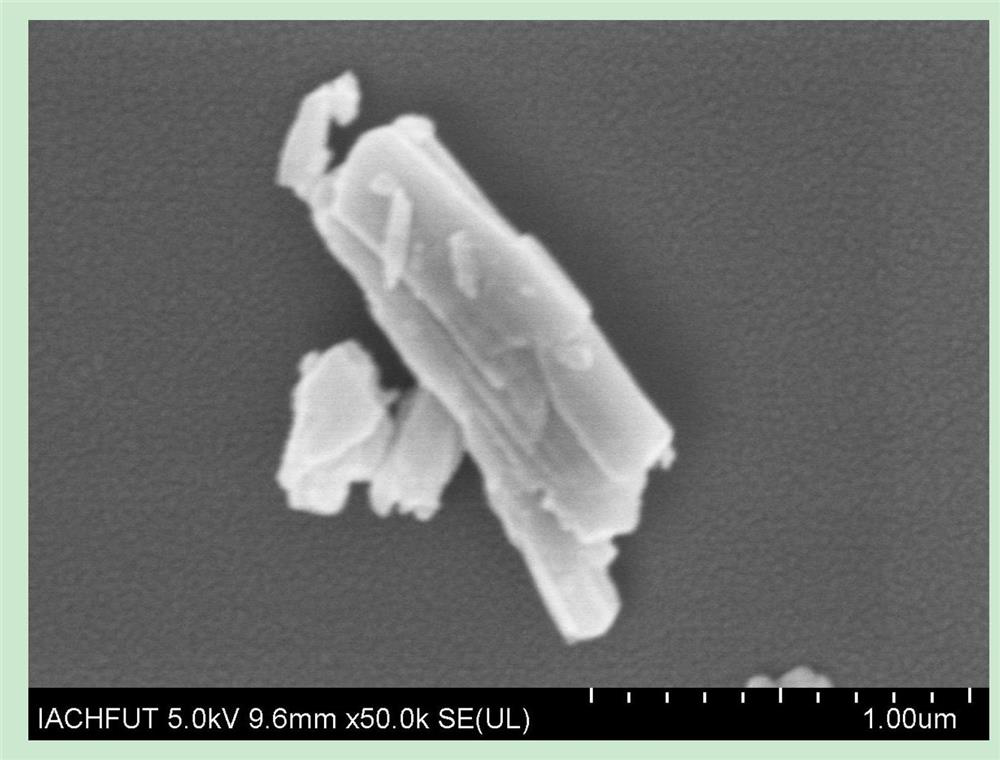

Preparation method of binary nickel cobalt selenide nanosheet material

A nanosheet, selenide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low yield, pollute the environment, cumbersome process, etc., achieve high yield, preparation The method is simple and the effect of chemical adsorption is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

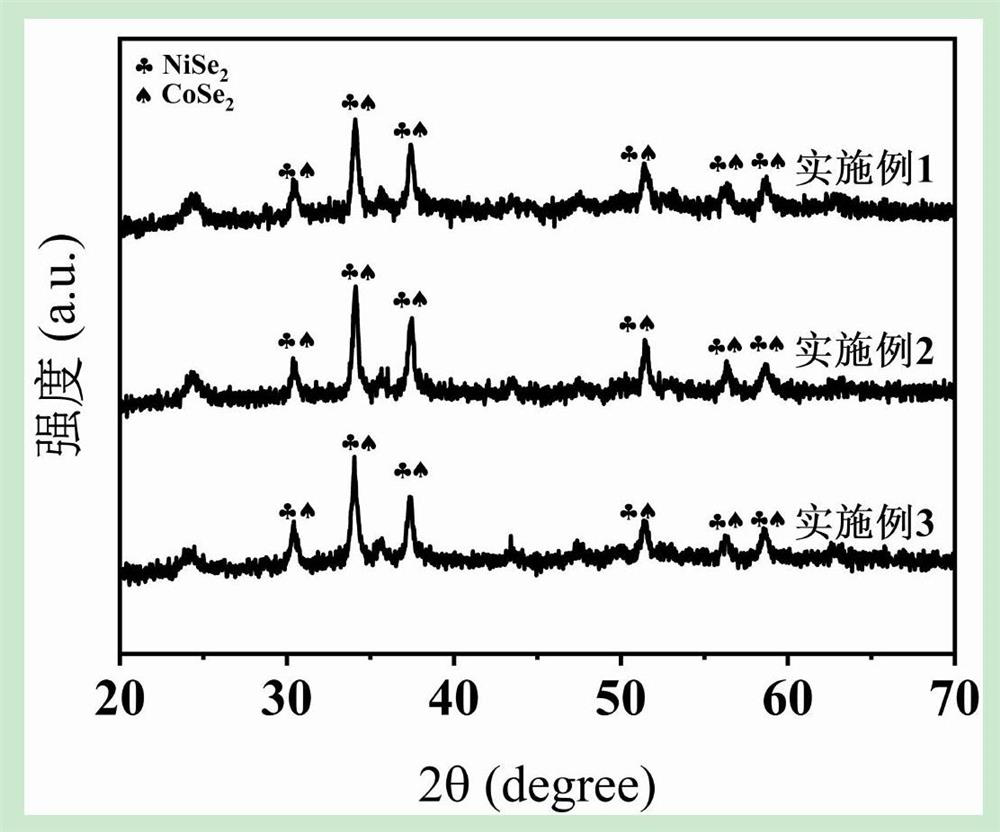

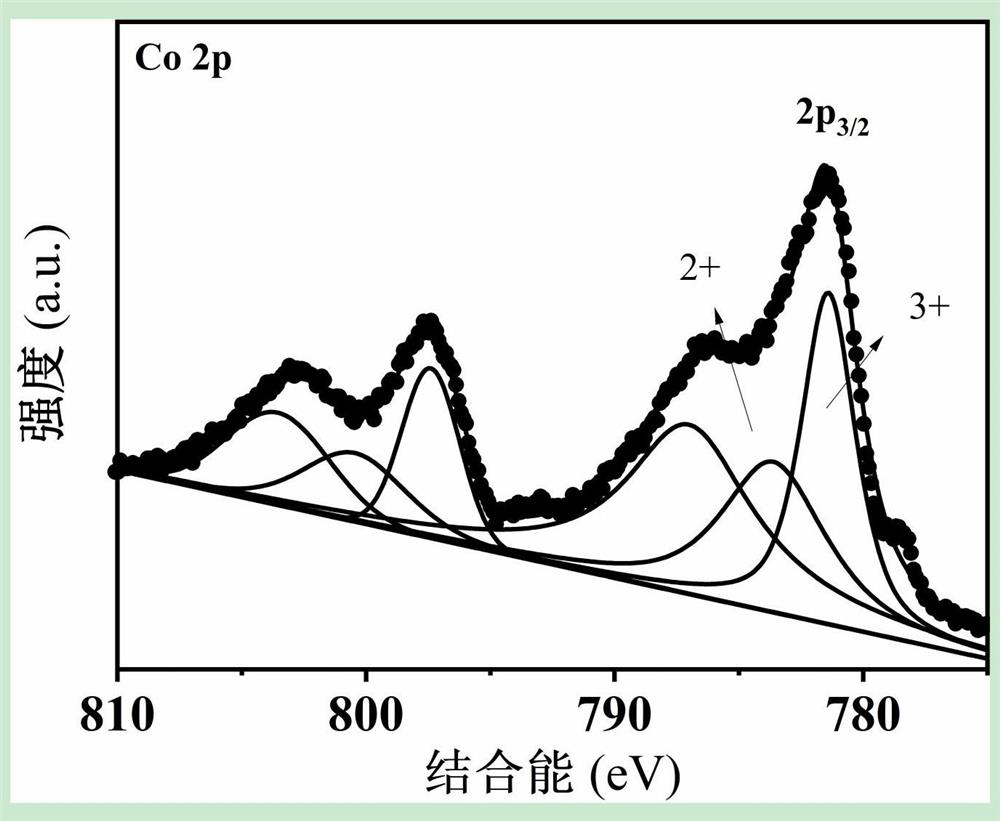

Embodiment 1

[0036] A preparation method of binary nickel cobalt selenide nanosheet material, comprising the following steps:

[0037] (1) 3mmol oxalic acid is placed in 20ml deionized water to carry out magnetic stirring for 5min, and the stirring speed is 600r / min, and then the oxalic acid solution is placed in a supersonicator to carry out ultrasonic dispersion 5min;

[0038] (2) 1mmol nickel nitrate, 2mmol cobalt nitrate are added in 40ml methanol, ultrasonic 5min, magnetic stirring 5min, stirring speed is 600r / min, the pink transparent nitrate solution obtained, wherein the mol ratio of nickel-cobalt ion is 1:2;

[0039] (3) pour the solution prepared in step (2) into the solution prepared in step (1), then stir the mixed solution for 5min to obtain a precursor solution;

[0040] (4) adding the obtained precursor solution in the step (3) into the inner liner of the autoclave, twisting the inner liner and putting it into the outer shell of the autoclave, putting the autoclave into the ...

Embodiment 2

[0044] A preparation method of binary nickel cobalt selenide nanosheet material, comprising the following steps:

[0045](1) 3mmol oxalic acid was placed in 20ml deionized water and carried out magnetic stirring for 5min, and the stirring speed was 700r / min, then the oxalic acid solution was placed in a supersonicator to carry out ultrasonic dispersion 5min;

[0046] (2) 1mmol nickel nitrate, 2mmol cobalt nitrate are added in 40ml methanol, ultrasonic 5min, magnetic stirring 5min, stirring speed is 700r / min, the pink transparent nitrate solution obtained, wherein the mol ratio of nickel-cobalt ion is 1:2;

[0047] (3) pour the solution prepared in step (2) into the solution prepared in step (1), then stir the mixed solution for 5min to obtain a precursor solution;

[0048] (4) adding the obtained precursor solution in the step (3) into the inner liner of the autoclave, twisting the inner liner and putting it into the outer shell of the autoclave, putting the autoclave into the...

Embodiment 3

[0052] A preparation method of binary nickel cobalt selenide nanosheet material, comprising the following steps:

[0053] (1) 3mmol oxalic acid was placed in 20ml deionized water and carried out magnetic stirring for 5min, and the stirring speed was 800r / min, and then the oxalic acid solution was placed in a supersonicator to carry out ultrasonic dispersion 5min;

[0054] (2) 1mmol nickel nitrate, 2mmol cobalt nitrate are added in 40ml methanol, ultrasonic 5min, magnetic stirring 5min, stirring speed is 800r / min, the pink transparent nitrate solution obtained, wherein the mol ratio of nickel-cobalt ion is 1:2;

[0055] (3) pour the solution prepared in step (2) into the solution prepared in step (1), then stir the mixed solution for 5min to obtain a precursor solution;

[0056] (4) adding the obtained precursor solution in the step (3) into the inner liner of the autoclave, twisting the inner liner and putting it into the outer shell of the autoclave, putting the autoclave int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com