An electrocatalyst zif-9(iii)/co LDH nanosheet composite material and preparation method thereof

A technology of ZIF-9 and electrocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of poor dispersion of composite materials, high temperature and high pressure, and price Expensive and other issues, to achieve the effect of improving wettability, improving conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

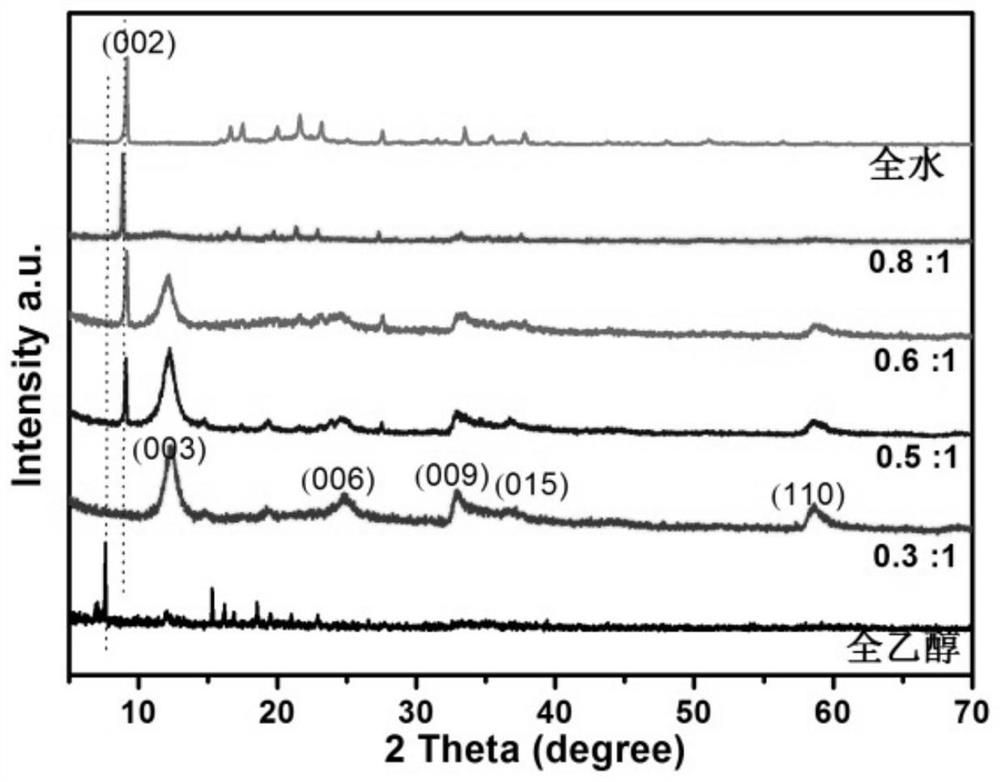

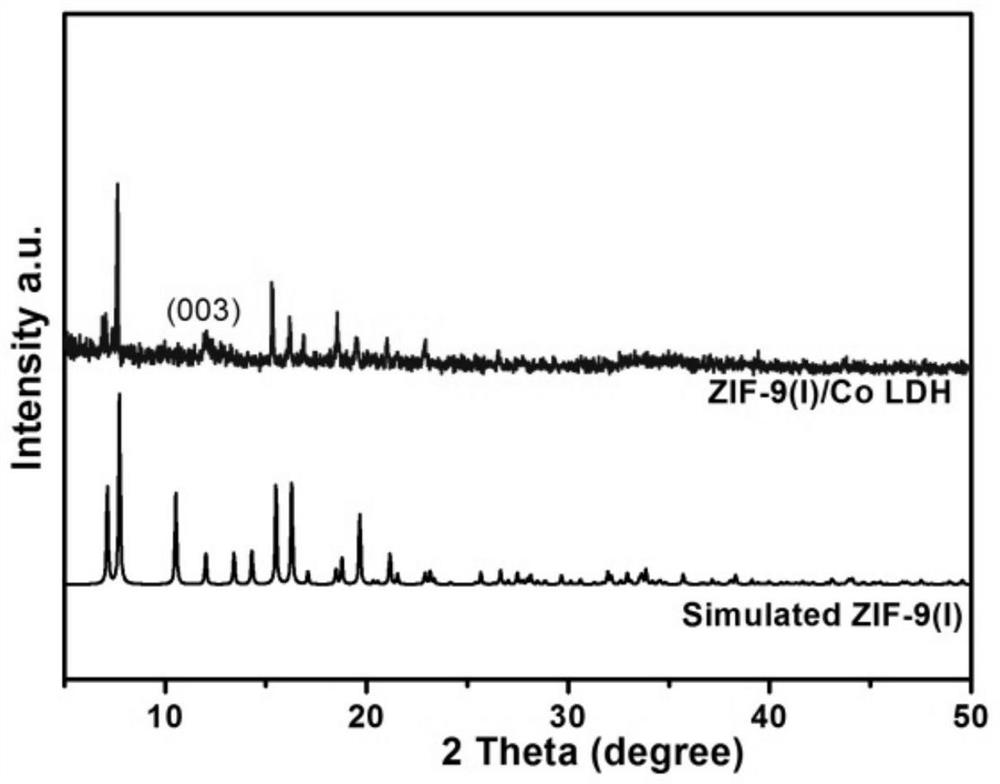

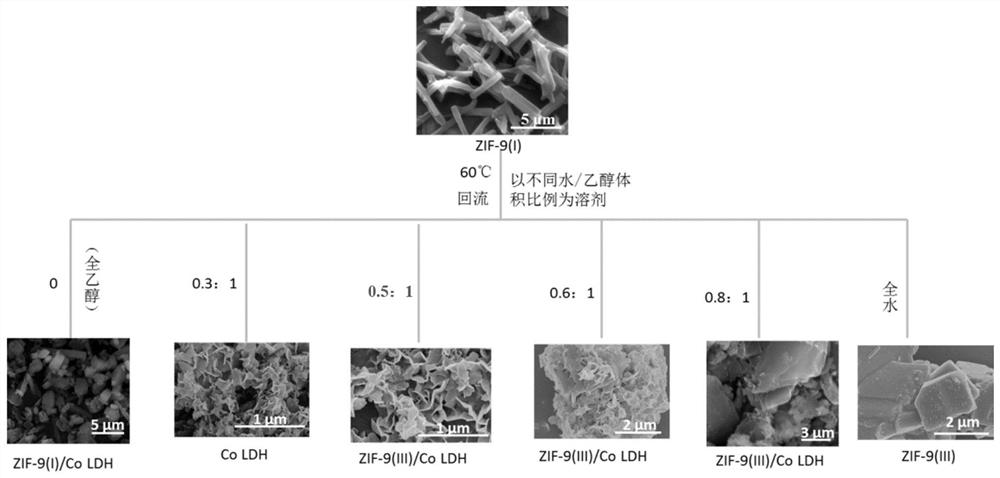

[0032] A preparation method of an electrocatalyst ZIF-9(III) / Co LDH nanosheet composite material, using imidazole metal organic framework ZIF9(I) as a precursor, comprising the following steps:

[0033] (1) Weigh 0.63g of cobalt nitrate hexahydrate, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent to obtain solution A; weigh 0.14g of benzimidazole, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent. , in N-dimethylformamide solvent to obtain solution B; the ultrasonic power is 250W, and the ultrasonic time is 10 minutes;

[0034] (2) Mix solution A and solution B and stir evenly to obtain mixed solution C; put it in an oil bath and reflux for 24 hours, then wash with N,N-dimethylformamide and dichloromethane respectively, and collect by centrifugation. To obtain a three-dimensional ZIF-9(I), the reflow temperature was set to 140°C;

[0035] (3) 0.08g ZIF-9(I) prepared by step (2) is mixed with 0.16g cobalt nitrate, disso...

Embodiment 7

[0038] Example 7 (the molar ratio of cobalt nitrate and benzimidazole is 2:1, and the mass ratio of ZIF-9(I) and cobalt nitrate is 1:1)

[0039] A preparation method of an electrocatalyst ZIF-9(III) / Co LDH nanosheet composite material, using imidazole metal organic framework ZIF9(I) as a precursor, comprising the following steps:

[0040] (1) Weigh 0.63g of cobalt nitrate hexahydrate, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent to obtain solution A; weigh 0.16g of benzimidazole, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent. , in N-dimethylformamide solvent to obtain solution B; the ultrasonic power is 400W, and the ultrasonic time is 5 minutes;

[0041] (2) Mix solution A and solution B and stir evenly to obtain mixed solution C; put it in an oil bath and reflux for 12 hours, then wash with N,N-dimethylformamide and dichloromethane respectively, and collect by centrifugation. To obtain a three-dimensional ZI...

Embodiment 8

[0043] Embodiment 8 (the molar ratio of cobalt nitrate and benzimidazole is 1:1, the mass ratio of ZIF-9 (I) and cobalt nitrate is 2:1)

[0044] A preparation method of an electrocatalyst ZIF-9(III) / Co LDH nanosheet composite material, using imidazole metal organic framework ZIF9(I) as a precursor, comprising the following steps:

[0045] (1) Weigh 0.63g of cobalt nitrate hexahydrate, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent to obtain solution A; weigh 0.31g of benzimidazole, and use ultrasonic to disperse evenly in 25mL of N,N-dimethylformamide solvent. , in N-dimethylformamide solvent to obtain solution B; the ultrasonic power is 400W, and the ultrasonic time is 5 minutes;

[0046] (2) Mix solution A and solution B and stir evenly to obtain mixed solution C; put it in an oil bath and reflux for 36 hours, then wash with N,N-dimethylformamide and dichloromethane respectively, and collect by centrifugation. To obtain a three-dimensional ZI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com