Profile control and plug removal integrated operation system and method for polymer flooding and injection well

A technology of polymer flooding, applied in chemical instruments and methods, drilling compositions, production fluids, etc., can solve the problems of short total construction time, inevitable entry of profile control agents, fast injection speed, etc., to avoid Effects of secondary damage, increasing the amount of inhaled blockage-removing working fluid, and improving the effect of blockage-removing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions for realizing the object of the present invention are further described below through specific embodiments. It should be noted that the technical solutions claimed in the present invention include but are not limited to the following embodiments.

[0039] As a specific embodiment of the present invention, this example describes an integrated operation method for profile control and plugging removal of polymer flooding and polywell, specifically, including the following steps:

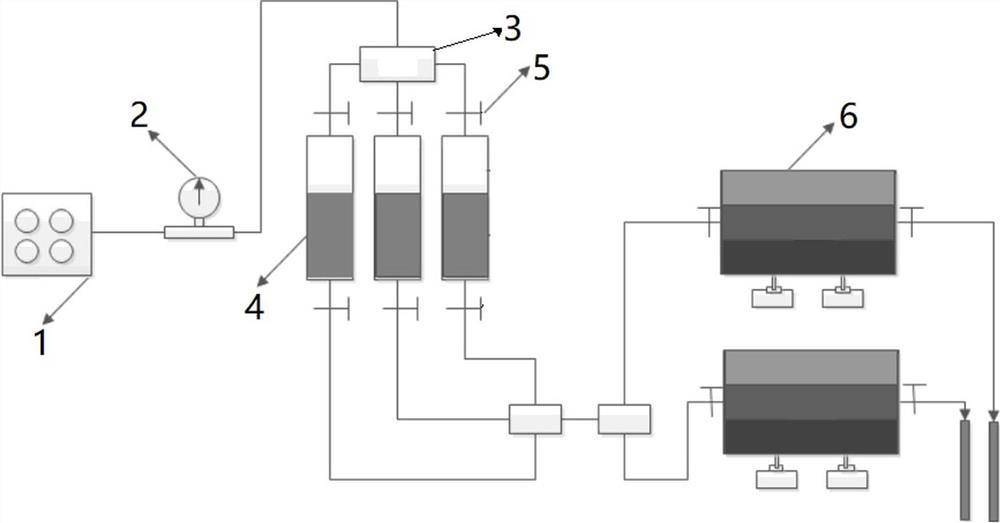

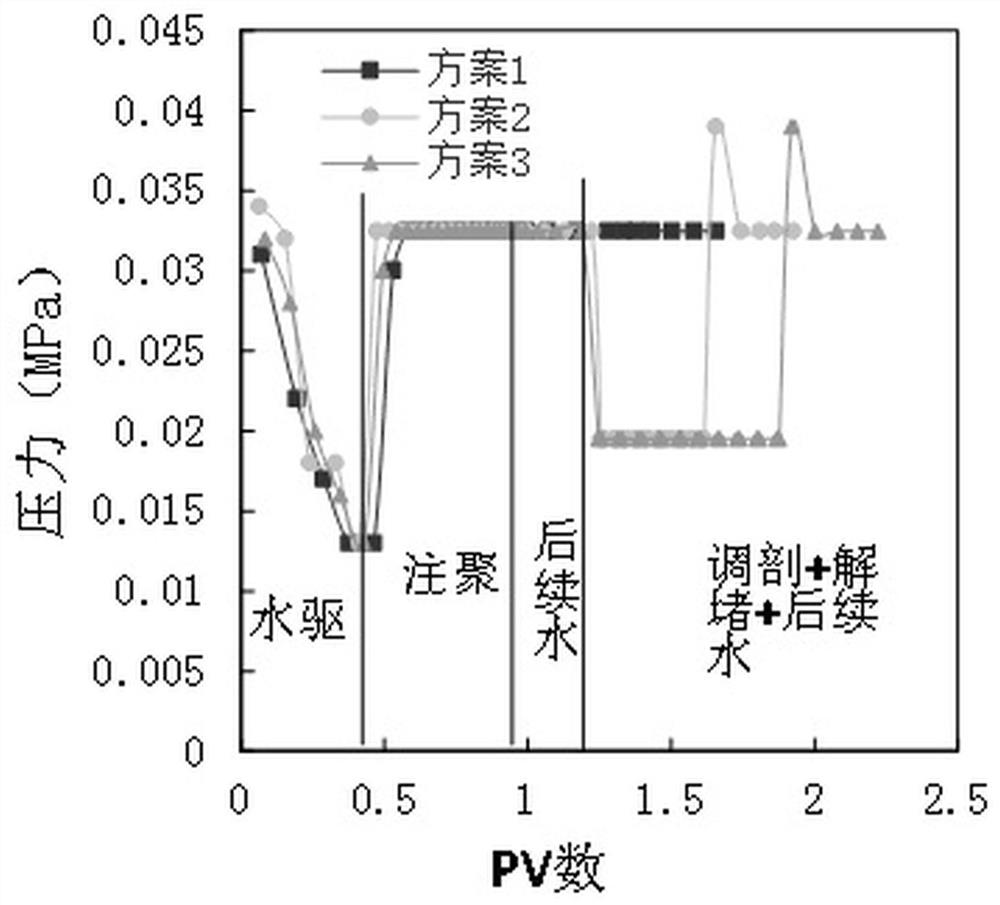

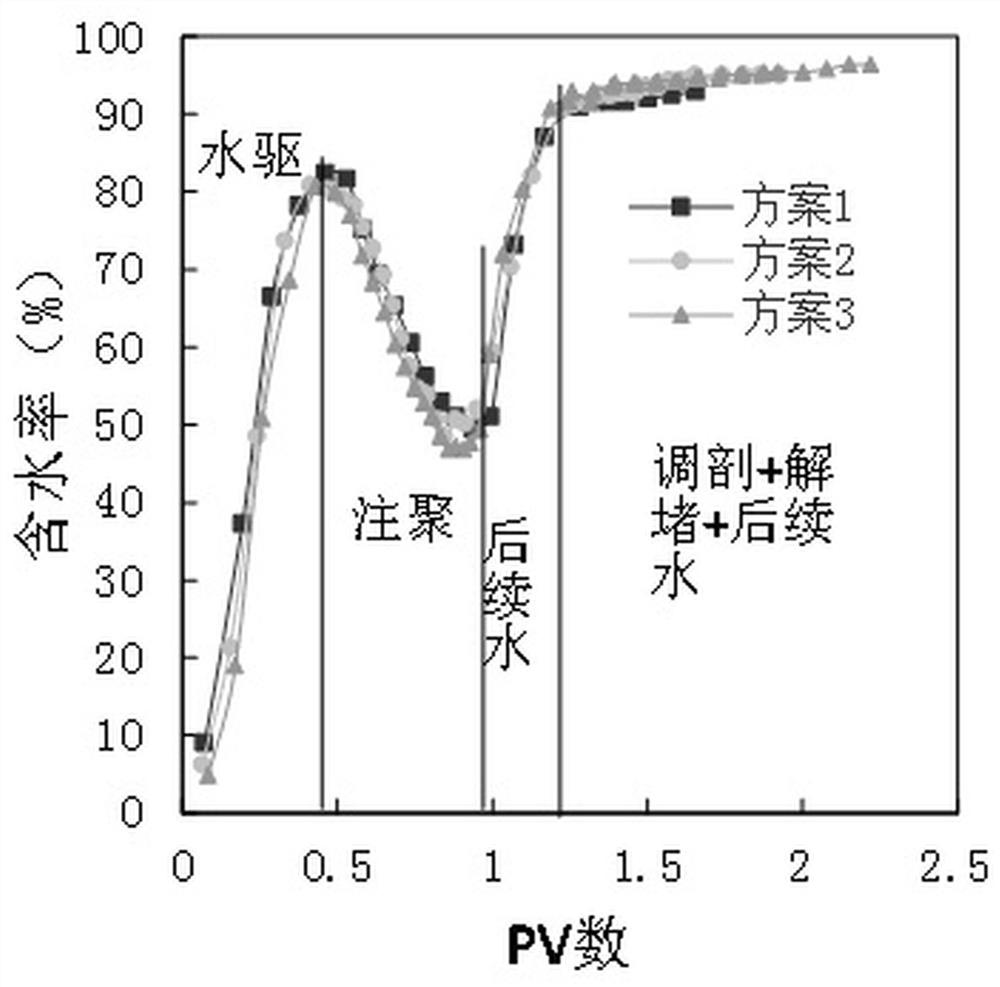

[0040] In the core production steps, the quartz sand epoxy resin cementation method is used to make heterogeneous core test blocks in two layers of high permeability and low permeability. The external dimensions of the core test blocks are: width × height × length = 4.5cm × 4.5cm × 30cm, among which, the permeability K of the high, medium and low layers in the high permeability core test block g 4500 / 2500 / 500×10 respectively -3 μm 2 , the permeability K of the high, medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com