Communication optical fiber testing method

An optical fiber testing and communication technology, applied in the field of optical fiber production, can solve the problems of cumbersome testing process, and achieve the effect of improving efficiency, saving operating procedures, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

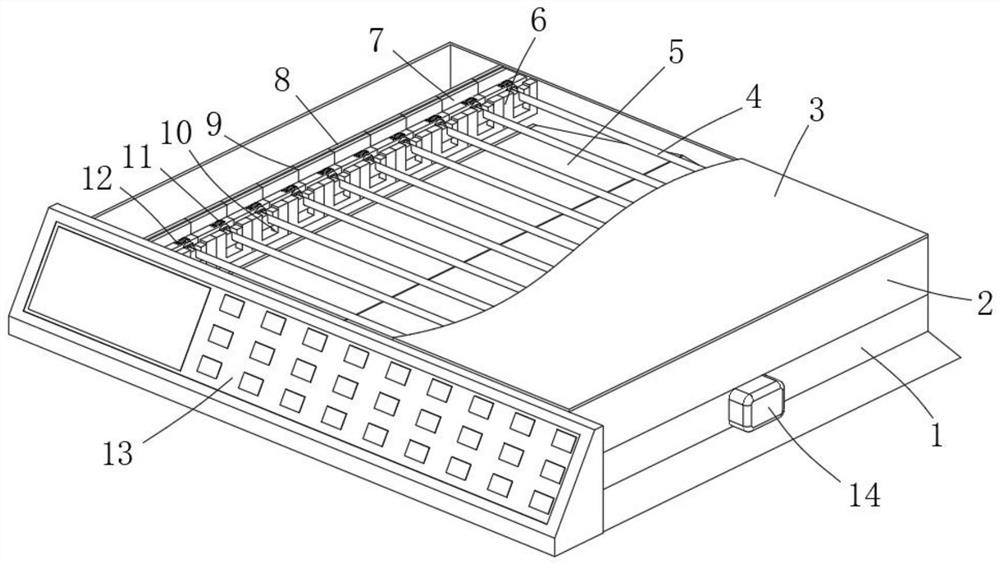

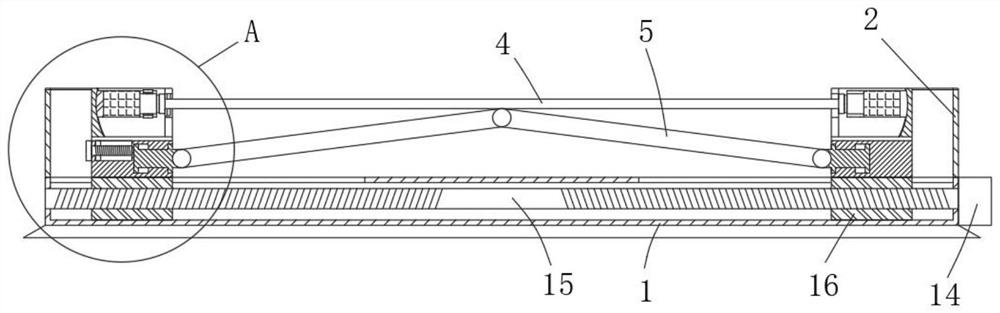

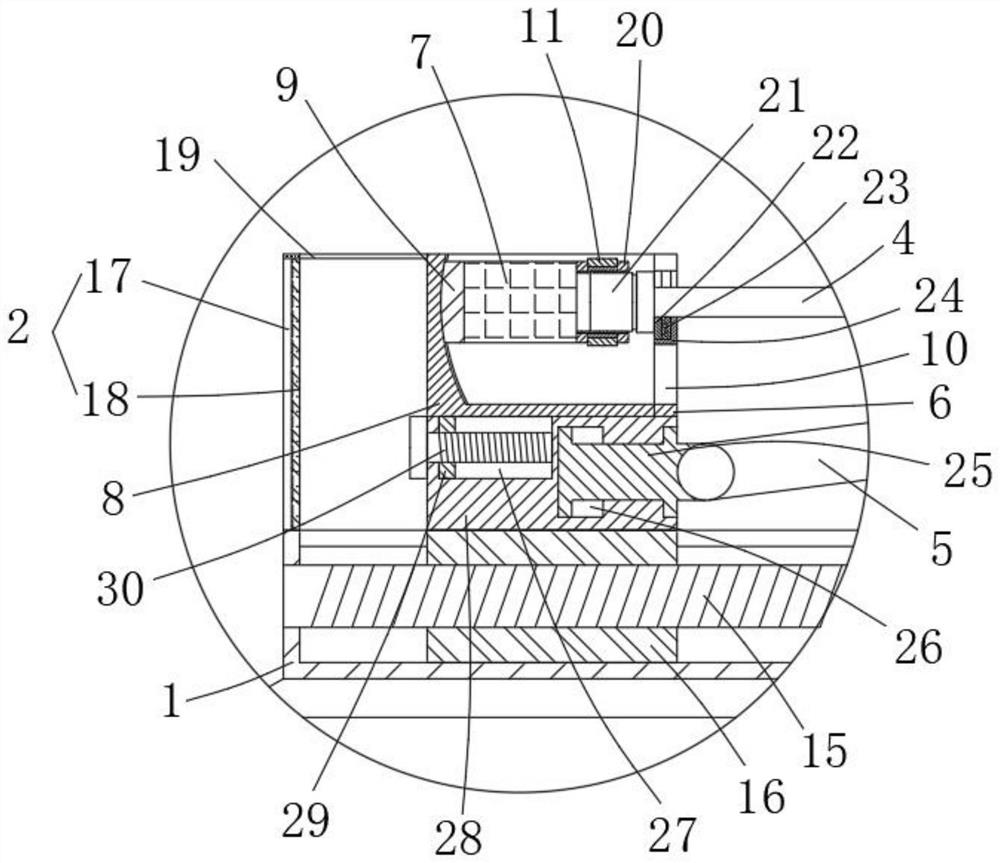

[0030] refer to Figure 1-5 , a communication optical fiber testing device, comprising a bottom case 1, an operation panel 13 is provided on one side of the bottom case 1, a support block 28 is provided on both sides of the top outer wall of the bottom case 1, and a drive mechanism is provided inside the bottom case 1 , the top outer walls of the two support blocks 28 are provided with a transverse block 8, and one side inner wall of the transverse block 8 is slidably connected with a damping slider 9, and one side outer wall of the two damping sliders 9 is fixedly connected to the light receiver 7 respectively. And the optical transmitter, the optical receiver 7 and the outer wall of one side of the optical transmitter are fixedly connected with a vertical plate 20, wherein the lateral outer wall of one vertical plate 20 is provided with evenly distributed first interface slots, and the lateral outer wall of the other vertical plate 20 is provided with There is a twisting mec...

Embodiment 2

[0040] A communication optical fiber testing method, using the communication optical fiber testing device described in Embodiment 1, the steps are as follows:

[0041] A, initial value measurement: insert the optical fiber connector 21 into the first interface slot and the interface slot 32 on both sides respectively, the optical fiber 4 is in a straight state, the pressure sensor 23 measures the pressure to zero, the optical transmitter sends out an optical signal, and passes through the optical fiber. 4 After transmission, the optical receiver 7 accepts the optical signal strength as the initial value;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com