Battery module testing device and testing method

A test device and battery module technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of long test cycle, difficult processing, high cost, etc., and achieve simple and convenient simulation method and short test time , the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

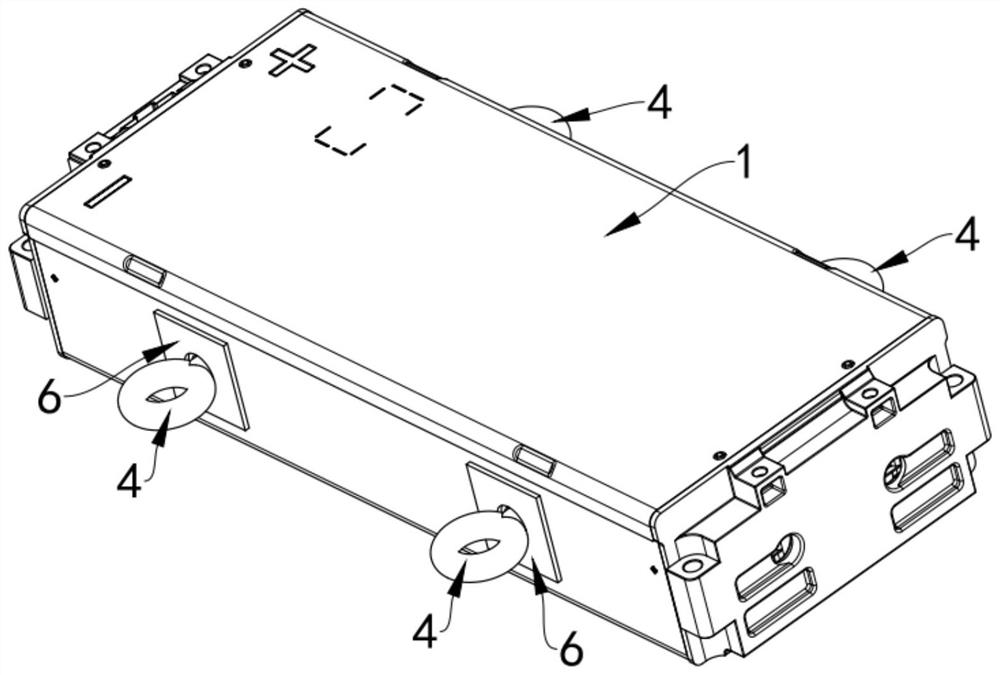

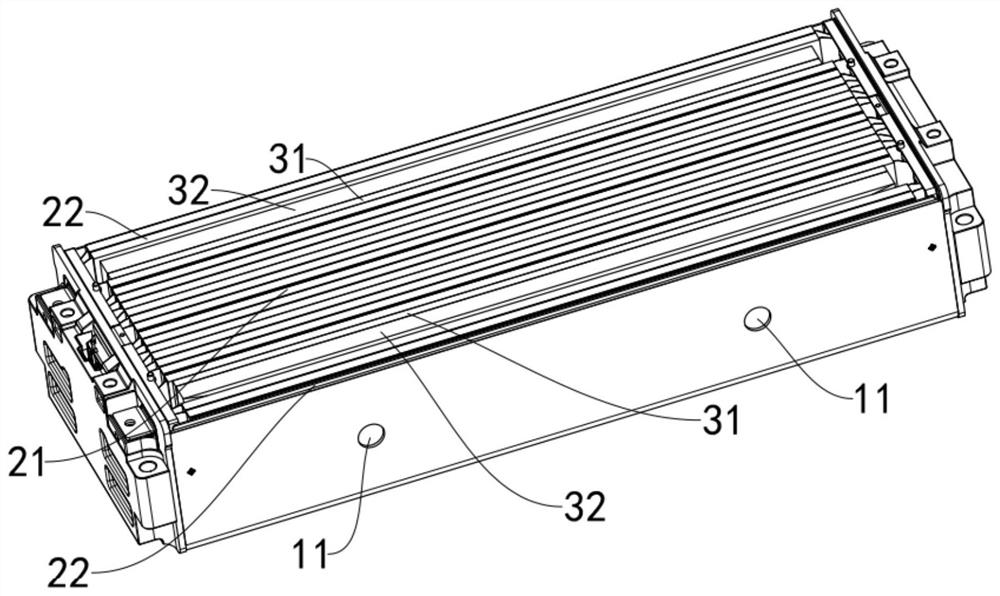

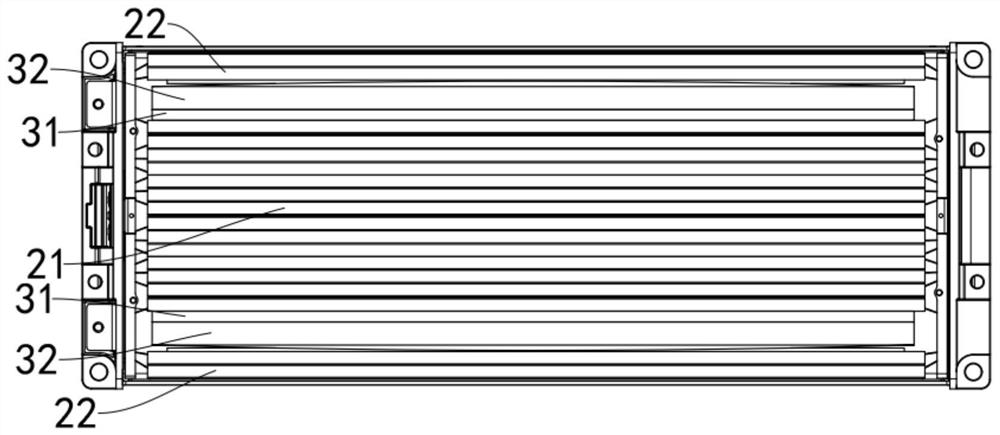

[0040] like Figures 1 to 7 As shown, a battery module testing device includes:

[0041] Module housing 1; the module housing 1 is provided with two parallel expansion simulation structures, there is a gap between the two expansion simulation structures, and there is also a gap between the expansion simulation structure and the inner wall of the housing , the gap is used to place the electric core; the two sides of the module housing 1 are symmetrically provided with a plurality of pull rings 4, and the pull rings 4 are connected to the expansion simulation structure;

[0042] The pull rod 5 is connected with the pull ring 4 .

[0043] In the present invention, the battery cells placed in the module housing 1 are tested through the expansion simulation structure and the pull ring 4 connected to the expansion simulation structure, and a better simulation can be achieved only by applying a pulling force to the pull ring 4. In the state of battery expansion, the simulation meth...

Embodiment 2

[0064] like Figures 1 to 7 As shown, a test method, the test steps are as follows:

[0065] Step S1: Assemble the module shell 1, the fixing plate 31, the expansion simulation plate 32, the pull ring 4, the pull rod 5 and the gasket 6 in a fixed assembly sequence, and place the unfilled cells in the assembly process. in the gap;

[0066] Step S2: fixing the assembled test device to the test bench;

[0067] Step S3: connecting the third connecting parts 53 of the two pull rods 5 to the tension machine, and adjusting the position of the tension machine so that the pull rods 5 are in a horizontal but unstressed state;

[0068] Step S4: start the tensile machine, apply a tensile force to the test device at a set speed, and simulate the process of battery expansion;

[0069] The set speed is 0.1~0.5mm / s. Using this speed can better simulate the process of cell expansion, and can better reflect the relationship between expansion force and displacement.

[0070] Step S5: record ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com