Analysis method of dimethyl oxalate

A technology of dimethyl oxalate and an analysis method, which is applied in the field of analysis of dimethyl oxalate, can solve the problems of dimethyl oxalate requiring heat treatment and cannot continuously automatically inject samples, and achieves the effect of improving analysis precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

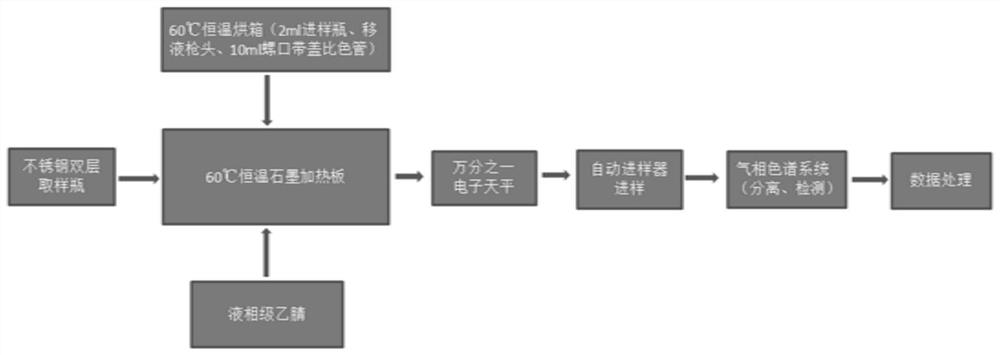

[0038] The invention provides an analytical method for dimethyl oxalate, which is specifically implemented according to the following steps:

[0039] Step 1, set gas chromatography parameters, and establish a dimethyl oxalate collection method:

[0040] Injection volume: 0.6ul, split ratio: 5:1, split flow 25ml / min, injection port temperature: 300℃;

[0041] Chromatographic column: DB624 60m×510um×3um, column flow: 5ml / min;

[0042]

[0043] Detector temperature: 300°C, air flow: 400ml / min, hydrogen flow: 40ml / min, makeup flow: 30ml / min;

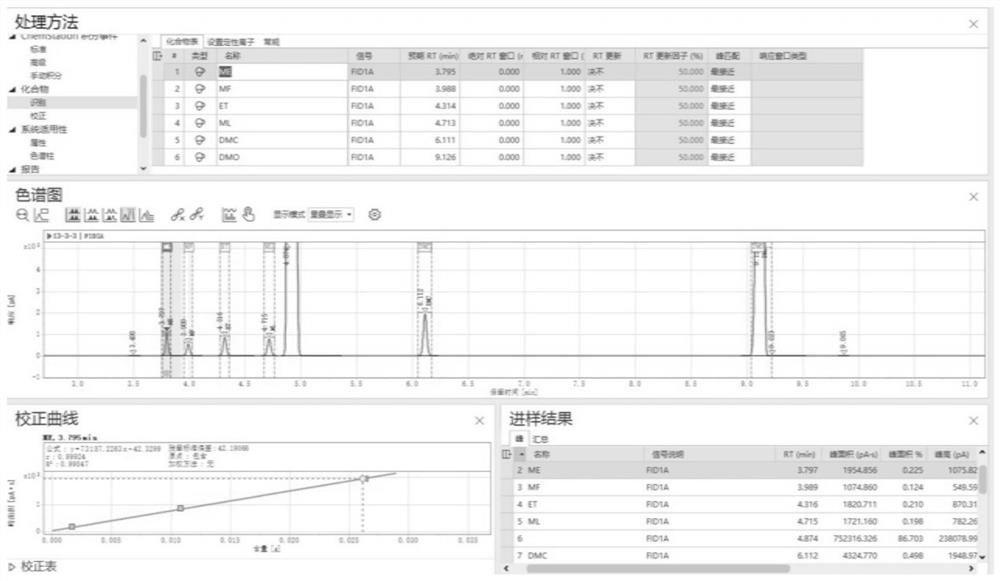

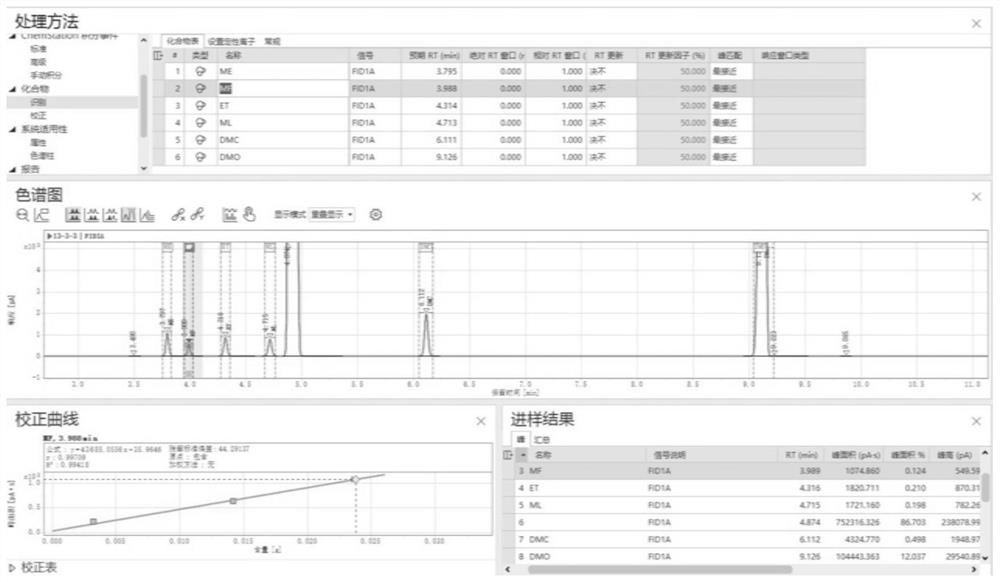

[0044] Step 2, through the standard sample determination, establish the dimethyl oxalate treatment method:

[0045] Step 2.1, configuration of chromatographic standard:

[0046] Take 0.1 ml of methanol, methyl formate, ethanol, methylal, dimethyl carbonate, and 0.1 g of dimethyl oxalate in six 25 ml co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com