3D detection method for computer rear shell

A detection method and 3D technology, applied in image analysis, instruments, calculations, etc., can solve the problems of increasing algorithm data processing volume, increasing detection cost, low detection accuracy, etc., to improve the speed of algorithm processing, improve dynamic repeatability, The effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

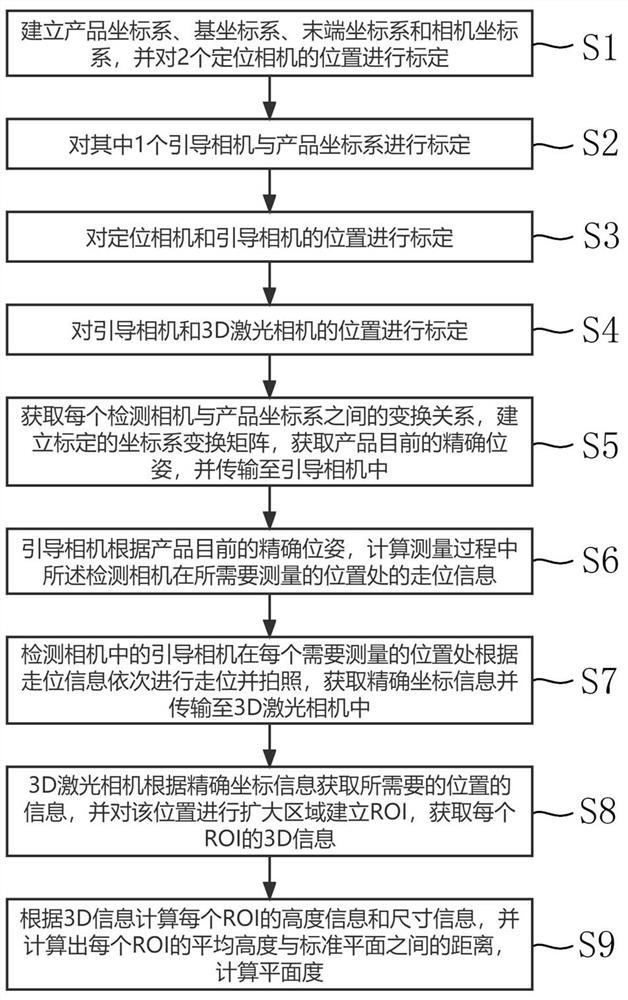

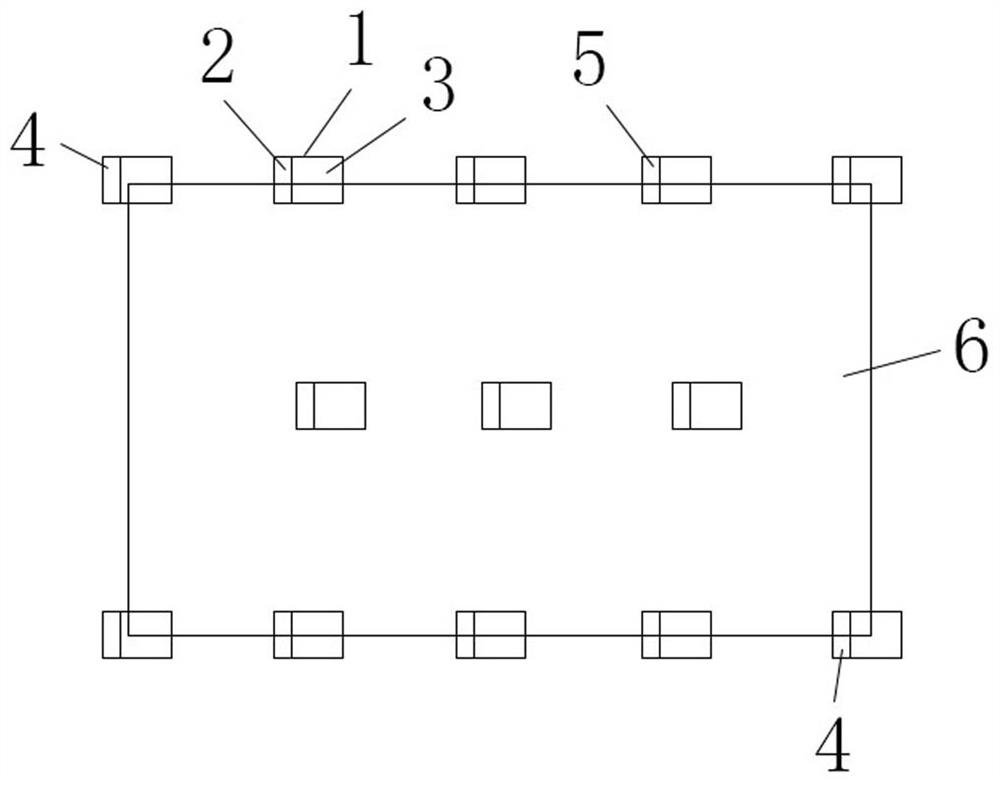

[0061] like Figure 1-Figure 2 As shown, this embodiment relates to a 3D detection method for a computer back case, including a manipulator and several groups of detection cameras 1 , each group of detection cameras 1 includes a 2D camera 2 and a 3D laser camera 3 ; The 2D camera 2 is set as the positioning camera 4, and the 2D camera 2 in the other detection cameras 1 is set as the guidance camera 5; specifically, the following steps are included:

[0062] S1. Establish a product coordinate system, a base coordinate system, an end coordinate system and a camera coordinate system, and calibrate the positions of the two positioning cameras 4;

[0063] S2, calibrating one of the guide cameras 5 and the product coordinate system;

[0064] S3, calibrating the positions of the positioning camera 4 and the guiding camera 5;

[0065] S4, calibrating the positions of the guidance camera 5 and the 3D laser camera 3;

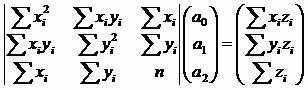

[0066] S5. After the calibration in steps S1-S4, obtain the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com