Manipulator for drill floor surface

A technology of drilling floor and manipulator, which is applied to manipulators, manufacturing tools, claw arms, etc., can solve the problems of manipulators occupying large space, high renovation costs, and high labor intensity, and achieves reduction of floor space, reduction of equipment use costs, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

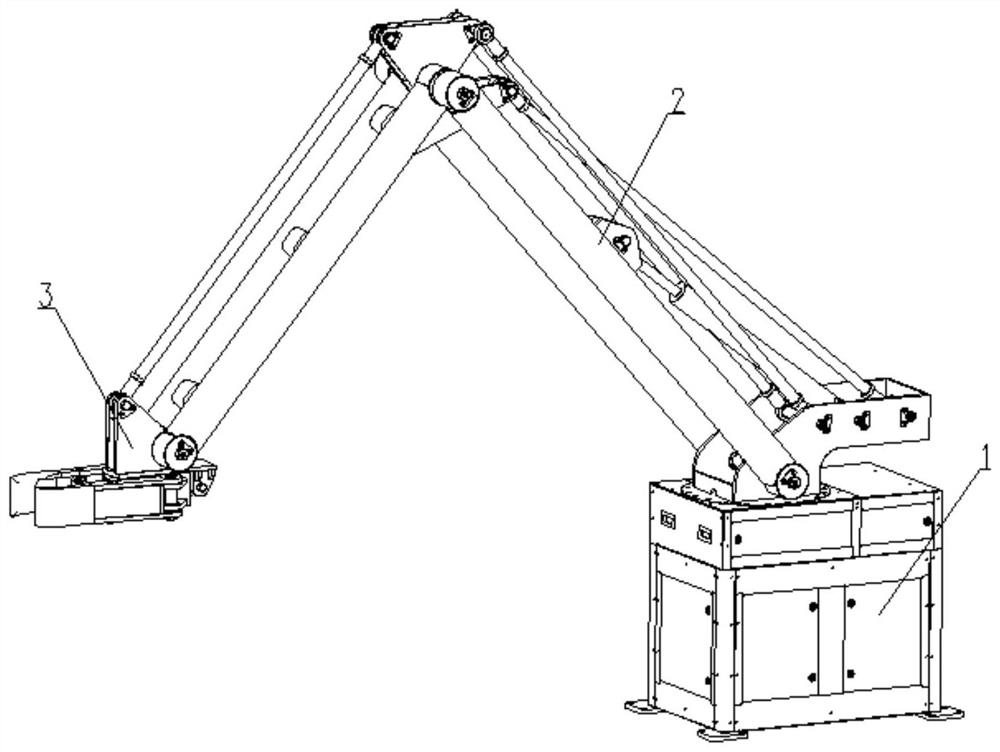

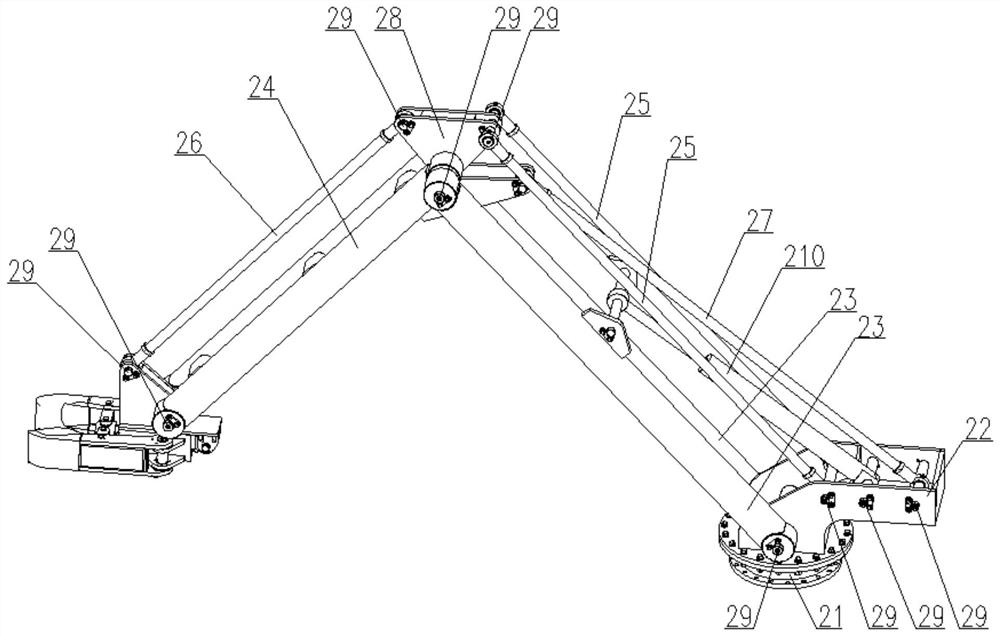

[0034] This embodiment relates to a drill floor manipulator, the main structure of which includes a driving base 1, a mechanical arm 2, and a pipe support tong 3, and the driving base 1 is fixedly installed on the drilling floor through the bottom fixing ears, and plays a supporting and fixing role for the entire system; The robotic arm 2 is fixed together with the rotating device 14 at the front position above the driving base 1 through the swivel base at the bottom. The end of the robotic arm 2 is hinged with the pipe holder 3 .

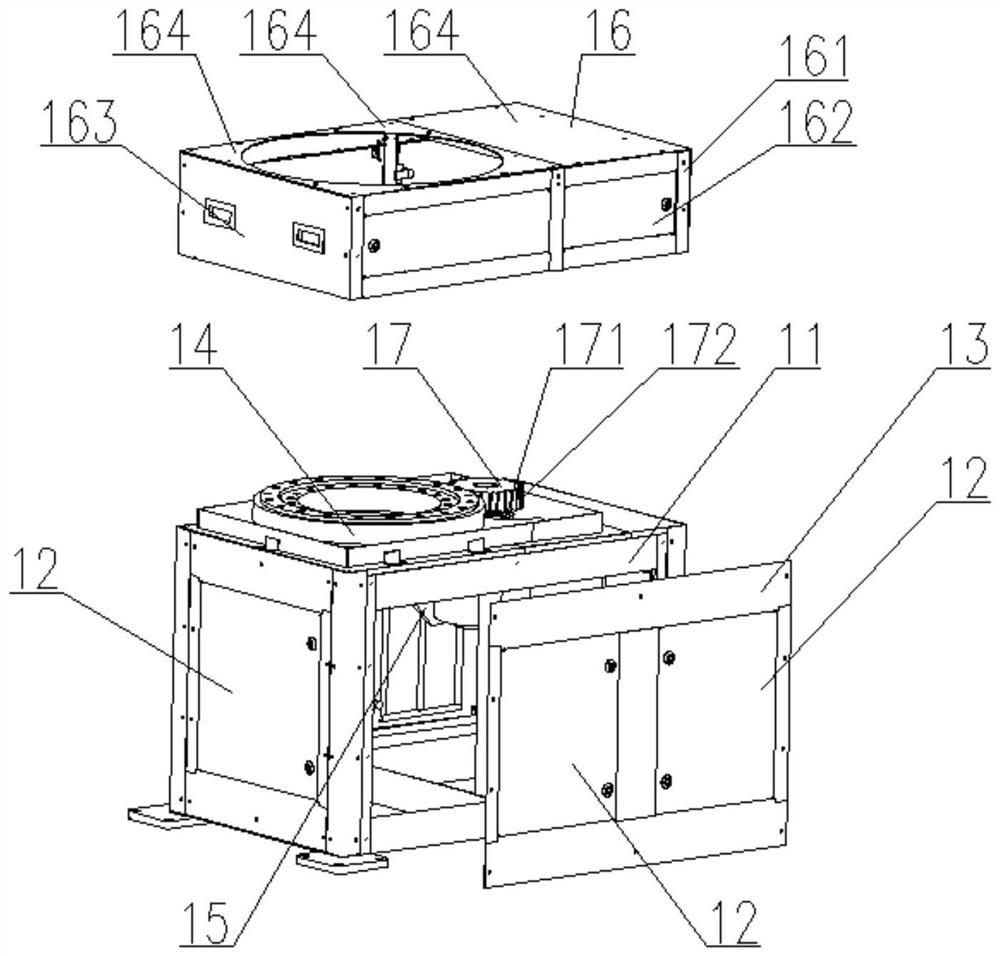

[0035] The structure of the drive base 1 includes a frame 11, an inspection door 12, a decorative cover 13, a rotating device 14, a drive mechanism mounting seat 15, a protective cover 16 and a rotating drive mechanism 17. The frame 11 is a square frame structure, and the bottom is provided with The fixing ears are used to fix the drive base 1 on the drilling floor; the access doors 12 are distributed on the surrounding sides of the frame 11 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com