Medium aluminum glass capable of absorbing ultraviolet rays as well as preparation method and application of medium aluminum glass

A technology of ultraviolet and aluminum glass, applied in the field of glass, can solve the problems of limited application and poor ultraviolet absorption effect of glass, and achieve the effect of low softening point temperature, excellent ultraviolet absorption efficiency and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] as attached figure 2 As shown, a second aspect of the embodiments of the present application provides a method for preparing the above-mentioned ultraviolet-absorbing medium aluminum glass, comprising the following steps:

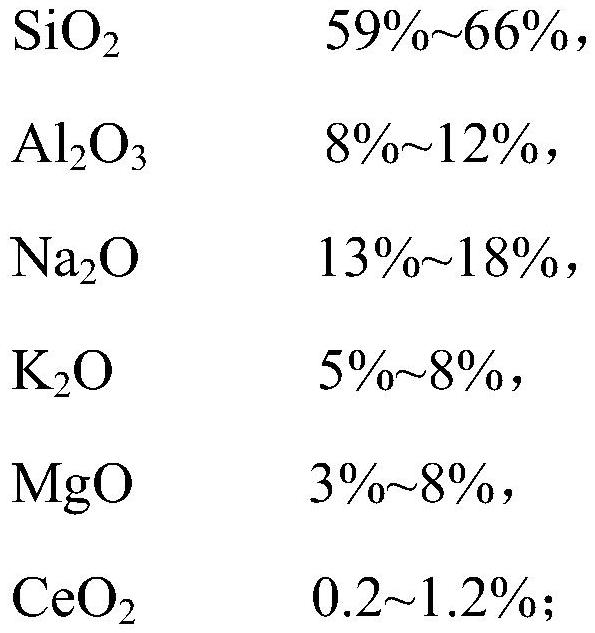

[0064] S10. Obtain the formula amount of SiO 2 , Al 2 O 3 , Na 2 O, K 2 O, MgO and CeO 2 Raw material components, each raw material component is melted into glass to obtain medium aluminum glass.

[0065] The SiO of the obtained formula quantity provided by the second aspect of the embodiment of the present application 2 , Al 2 O 3 , Na 2 O, K 2 O, MgO and CeO 2After the raw material components are obtained, each raw material component is melted into glass, so that the middle aluminum glass that absorbs ultraviolet rays can be obtained. The ultraviolet-absorbing medium aluminum glass of the embodiment of the present application has wide adaptability to the preparation process, and is suitable for industrialized large-scale production and...

Embodiment 1

[0074] Embodiments 1 to 5 respectively provide a medium aluminum glass that absorbs ultraviolet rays. The components of each embodiment and their mass percentages are shown in Table 1 below. The float process is used to mix the glass raw material components and then sequentially melt, Clarification, homogenization, forming and annealing process, and finally cut to obtain a medium aluminum glass plate with a thickness of 1.1mm for subsequent testing.

[0075] Table 1

[0076]

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Softening point temperature | aaaaa | aaaaa |

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com