PG82-22 grade modified asphalt and production method thereof

A technology of modified asphalt and production method, which is applied in building components, building insulation materials, buildings, etc., which can solve the problems of high difficulty in production technology, poor storage stability of modified asphalt, and insufficient low-temperature crack resistance, so as to improve anti-fatigue Cracking and low-temperature cracking performance, excellent anti-rutting performance and anti-aging performance, effects of excellent anti-rutting and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

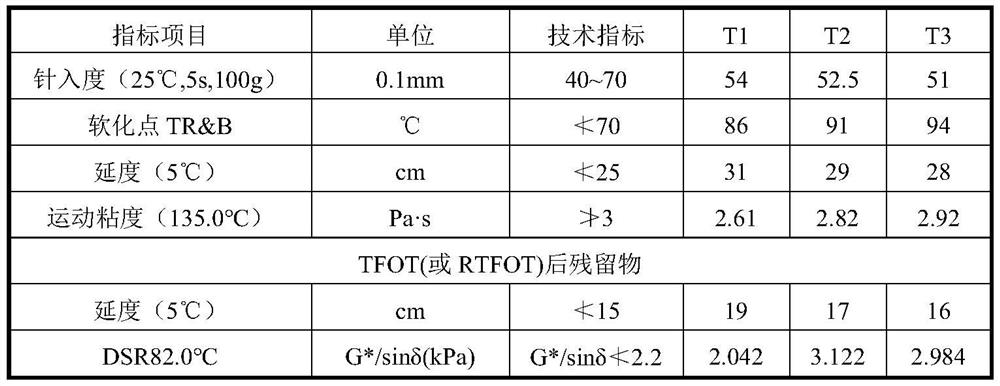

Embodiment 1

[0029] This example is to prepare a PG82-22 grade modified asphalt. The components of the modified asphalt in parts by weight include: 100 parts by weight of road petroleum asphalt, 4.0-6.0 parts by weight of SBS modifier, and 0-6.0 parts by weight of rubber oil. 3.0 parts by weight, 0-3.0 parts by weight of PG reinforcing agent, and 0.1-0.5 parts by weight of stabilizer; wherein, the road petroleum asphalt has a penetration of 60-800.1mm at 25°C and a straight line with a ductility of >100cm at 10°C. Distilled asphalt; specifically, at least one of imported South Korean Ssangyong 70# asphalt, South Korean SK70# asphalt, South Korean GS70# asphalt and domestic asphalt Dalian Xitai 70#, Zhenhai 70#, Shandong Runcheng 70#, Shandong Dongbo 70#, At least one of Shandong Haiyou 70# is mixed in proportion. Generally, the imported asphalt is 60-80%, and the domestic asphalt is 20-40%. The preferred combination and ratio is 70% Korea Ssangyong 70#+30% Dalian West Pacific 70#, 60% Kor...

Embodiment 2

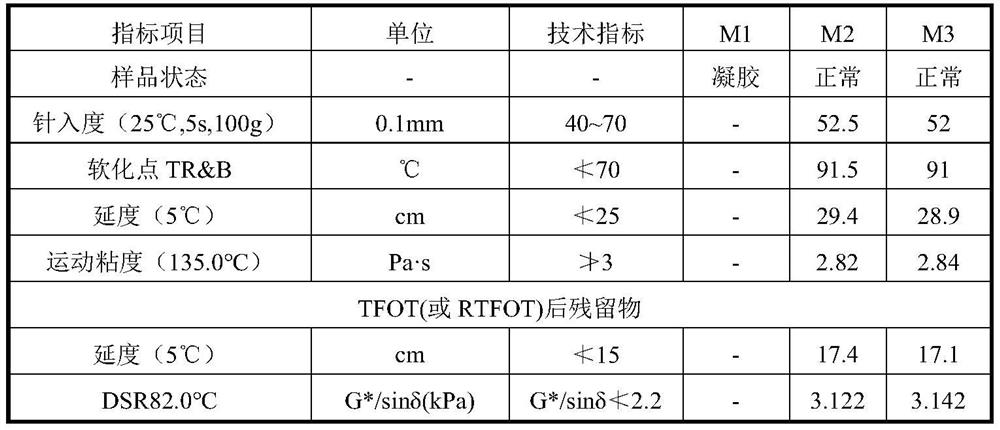

[0040] 70,000kg of South Korea Ssangyong 70# asphalt and 30,000kg of Dalian West Pacific 70# asphalt were rapidly heated to 130°C from the raw material tank through the heat exchanger, pumped into a 100-ton high-temperature tank, stirred for 2 hours, and then rapidly heated to 180°C through the heat exchanger. ℃, pumped into the workshop reactor; at the same time, the SBS of 4800kg of Sinopec YH791H was lifted into the reactor through the frequency conversion transfer pipe for pre-mixing modification; , 0.25 unit) grinded once into the finished product tank, and pumped 1000kg of rubber oil, opened the finished product tank and stirred for 2h; then slowly and evenly added 160kg of stabilizer, and continued to stir for 2 hours; then 500kg of HW was slowly and evenly passed through the hopper elevator The PG82-22 modified asphalt was prepared by adding it into the finished product tank, keeping the temperature at 175°C, and controlling the feeding time to 1.5 hours.

Embodiment 3

[0042] 60,000kg of Ssangyong 70# asphalt and 40,000kg of Shandong Runcheng 70# asphalt were quickly heated to 130°C from the raw material tank through a heat exchanger, pumped into a 100-ton high-temperature tank, stirred for 1.5 hours, and then rapidly heated to 180°C through a heat exchanger. ℃, pumped into the workshop reactor; at the same time, 4800kg of SBS of PetroChina Dushanzi T6302H was lifted into the reactor for premixing modification through the frequency conversion transfer pipe; To 0.3, 0.25 units) grind once into the finished product tank, and pump 500kg of rubber oil, open the finished product tank and stir for 2h; then slowly and evenly add 150kg of stabilizer, continue to stir for 2.5 hours; then 500kg of HW is passed through the hopper elevator Slowly and evenly add it into the finished product tank, keep the temperature at 180°C, and control the feeding time to 1 hour. After the feeding is completed, continue stirring for 4 hours to obtain PG82-22 modified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com