Plugging and water plugging system and preparation method thereof

A water system and hydraulic technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor retention, long thickening time, insoluble, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

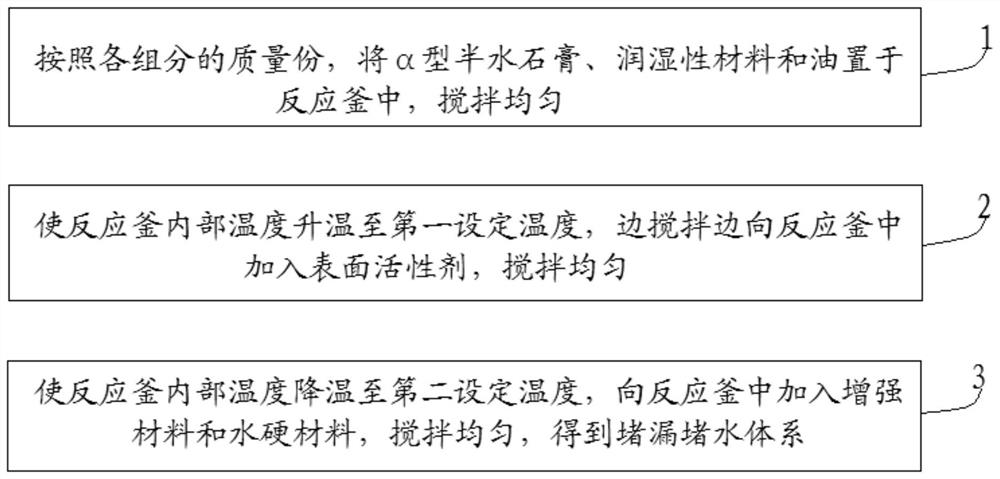

[0058] On the other hand, the embodiment of the present invention also provides the preparation method of any of the above-mentioned leakage and water plugging systems, and the preparation method of the leakage and water plugging system comprises the following steps:

[0059] Step 1. According to the mass parts of each component, put α-type hemihydrate gypsum, wetting material and oil in a reaction kettle and stir evenly.

[0060] Step 2: Raise the temperature inside the reaction kettle to the first set temperature, add surfactant to the reaction kettle while stirring, and stir evenly.

[0061] Step 3, cooling the internal temperature of the reaction kettle to the second set temperature, adding reinforcing material and hydraulic material to the reaction kettle, and stirring evenly to obtain a leakage and water blocking system.

[0062] Through the above preparation method, the different components are added in sequence in the above order, and a system for plugging leaks and wa...

Embodiment 1

[0080] The present embodiment 1 provides a system for plugging leaks and water, and the system for plugging leaks and water includes the following components by weight: 100 parts by weight of α-type hemihydrate gypsum;

[0081] 130 parts by weight of No. 3 white oil;

[0082] 40 parts by weight of Portland oil well cement;

[0083] 0.5 parts by weight of polyoxyethylene sorbitan monostearate;

[0084] 0.5 parts by weight of polypropylene fibers;

[0085] 2 parts by weight of modified asphalt powder.

[0086] The plugging and water blocking system is prepared by the following method: pour the designed amount of α-type hemihydrate gypsum, modified asphalt powder and No. 3 white oil into a 1000L enamel reaction kettle, open and stir until the above-mentioned α-type hemihydrate gypsum and Portland oil well cement dissolves uniformly in oil.

[0087] Heating was carried out to make the internal temperature of the enamel reaction kettle rise to 35°C, and the designed amount of p...

Embodiment 2

[0092] This embodiment 2 provides a system for plugging leaks and water, and the system for plugging leaks and water includes the following components by weight: 100 parts by weight of α-type hemihydrate gypsum;

[0093] 140 parts by weight of No. 5 white oil;

[0094] 50 parts by weight of Portland oil well cement;

[0095] 0.7 parts by weight of polyoxyethylene sorbitan monostearate;

[0096] 1 part by weight of polyester fiber;

[0097] 4 parts by weight of modified asphalt powder

[0098] The leak and water plugging system is prepared by the following method: pour the designed amount of α-type hemihydrate gypsum, modified asphalt powder and No. 5 white oil into a 1000L enamel reaction kettle, open and stir until the above-mentioned α-type hemihydrate gypsum and Portland oil well cement dissolves uniformly in oil.

[0099] Heating was carried out to make the internal temperature of the enamel reaction kettle rise to 33 ° C, and the designed amount of polyoxyethylene sor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com