Biomass gasification furnace

A gasifier and biomass technology, which is applied in the fields of biofuels, combustible gas production, petroleum industry, etc., can solve the problems of high energy consumption and high construction cost, and achieve the effect of reducing production cost and stabilizing combustible gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or replacement made based on the teachings of the present invention belongs to the protection scope of the present invention.

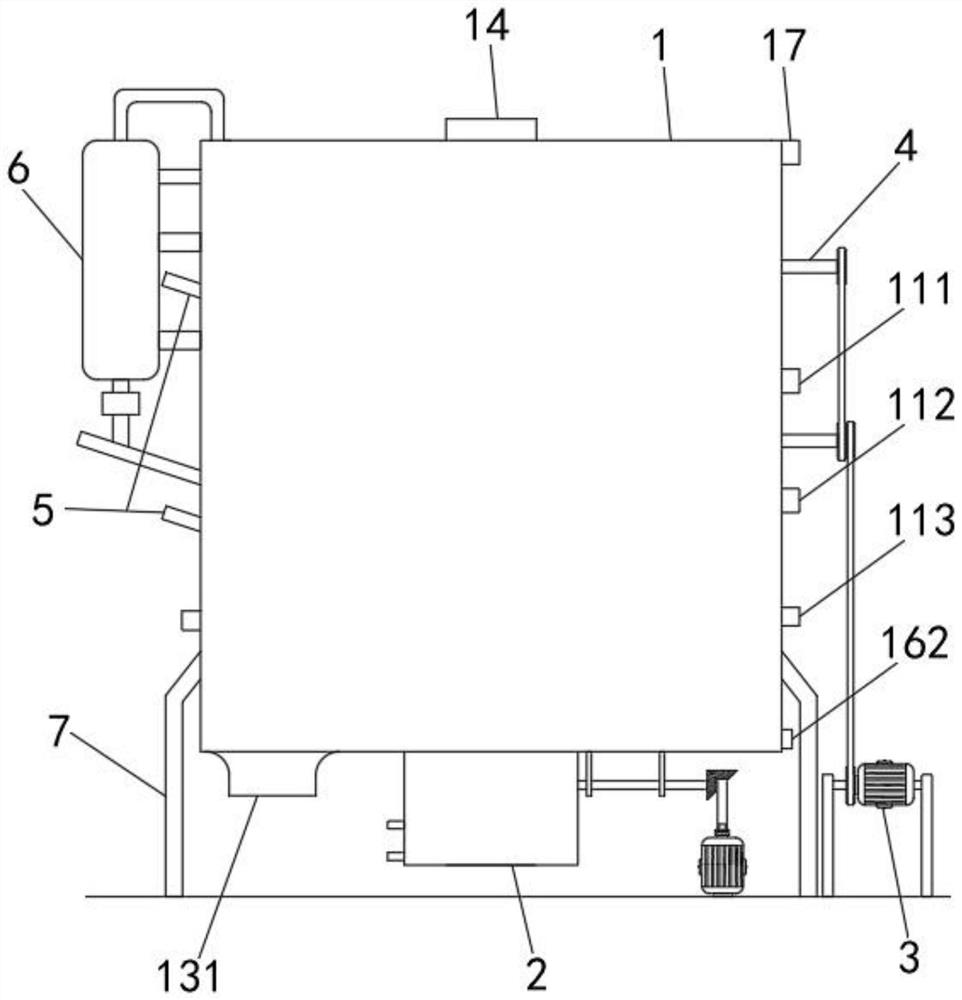

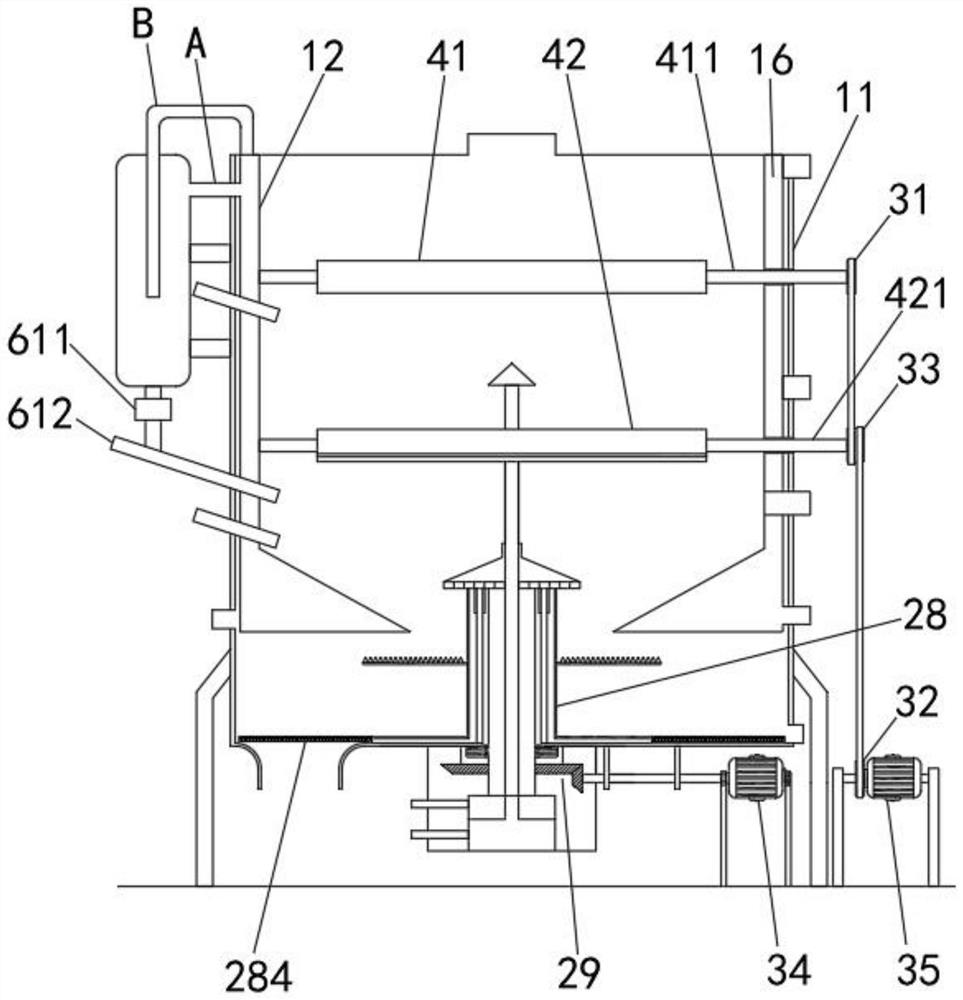

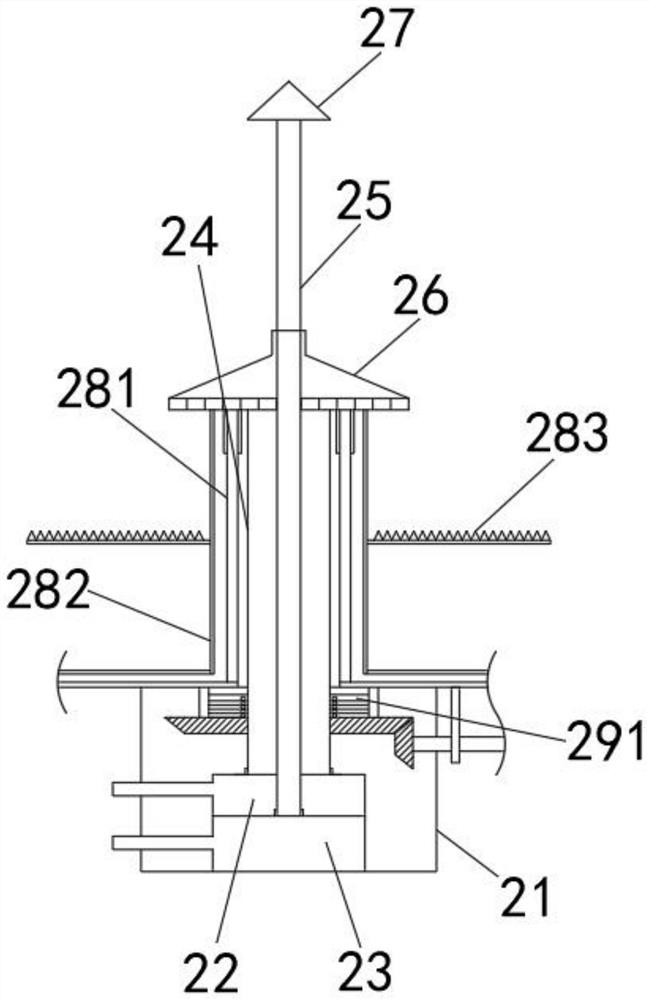

[0033] The invention discloses a biomass gasifier, refer to figure 1 , a biomass gasification furnace, comprising a furnace body 1, an air inlet device 2, an igniter 5 and a purification device 6, the air inlet device 2 is arranged in the middle of the bottom of the furnace body 1, and the igniter 5 is arranged in the upper part of the furnace body 1, The top of the furnace body 1 is provided with a purification device 6 that communicates with its inner cavity; after the biomass raw material enters the furnace body 1, the air inlet device 2 starts to supply air to the furnace, and the igniter 5 is ignited under the aid of ventilation to make the biomass raw material burn in the furnace. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com