Totally-synthesized wind power main gear box lubricating oil, production device and preparation method

A technology of main gearbox and production equipment, applied in the field of lubricating oil, which can solve the problems of shortened service life of oil products, poor foam performance, poor rubber compatibility, etc., and achieve reduced oil, good low-temperature fluidity, and high viscosity index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

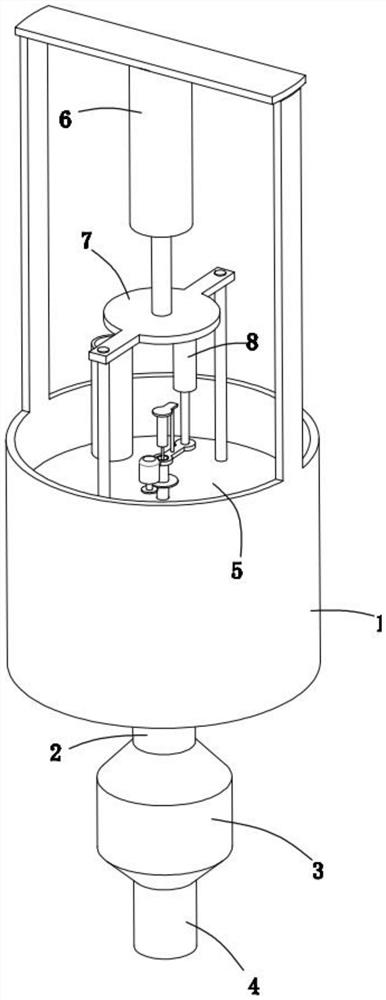

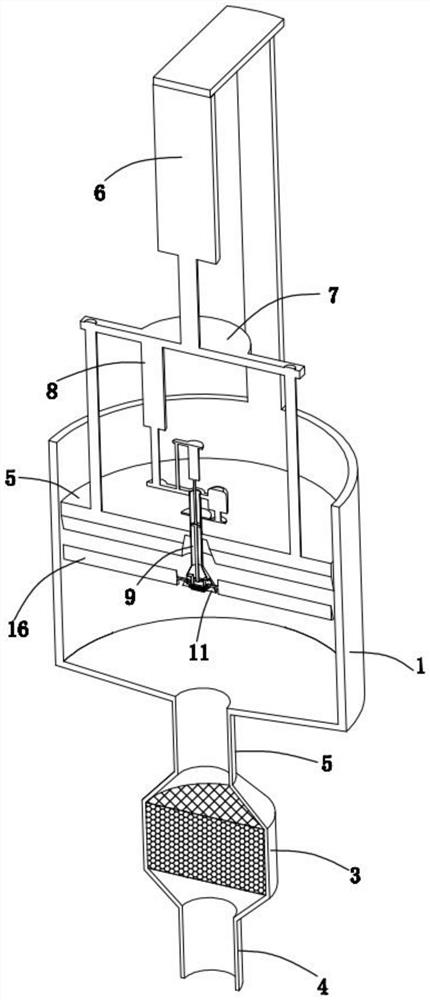

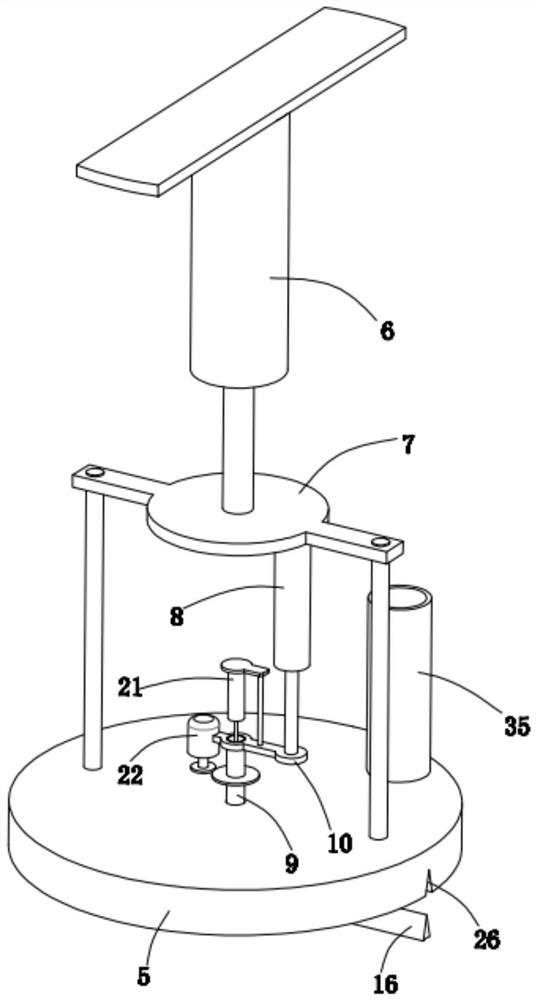

Method used

Image

Examples

Embodiment 1

[0038] A fully synthetic wind power main gearbox lubricating oil, the formula of its raw materials by weight is as follows:

[0039] 80 parts of polyalphaolefin base oil;

[0040] 5 parts of synthetic ester base oil;

[0041] 0.3 part of extreme pressure antiwear agent: the extreme pressure antiwear agent is any one or more of phosphoric acid esters, phosphorothioate esters, organic borate esters, and vulcanized olefins;

[0042] 0.3 part of antioxidant: antioxidants are 4,4-methylenebis 2,6-di-tert-butylphenol, 2,6-di-tert-butyl-p-cresol, 4,4-bisα,α-di Any one or more of methylbenzyldiphenylamine and p-dioctyldiphenylamine;

[0043] 0.1 part of rust inhibitor: the rust inhibitor is any one or more of sulfonates, macromolecular carboxylic acids, benzotriazole and derivatives thereof;

[0044] 0.1 part of anti-emulsifier: anti-emulsifier is any one or more of polyethers, amine and epoxy compound condensate;

[0045] 0.005 part of anti-foaming agent: the anti-foaming agent i...

Embodiment 2

[0057] As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the formula by weight of its raw materials is as follows:

[0058] 90 parts of polyalphaolefin base oil;

[0059] 10 parts of synthetic ester base oil;

[0060] 1.5 parts of extreme pressure anti-wear agent: the extreme pressure anti-wear agent is any one or more of phosphoric acid esters, phosphorothioate esters, organic borate esters, and sulfurized olefins;

[0061] 1.5 parts of antioxidants: antioxidants are 4,4-methylenebis 2,6-di-tert-butylphenol, 2,6-di-tert-butyl-p-cresol, 4,4-bisα,α-di Any one or more of methylbenzyldiphenylamine and p-dioctyldiphenylamine;

[0062] 1 part of rust inhibitor: the rust inhibitor is any one or more of sulfonates, macromolecular carboxylic acids, benzotriazole and its derivatives;

[0063] 1.5 parts of anti-emulsifier: the anti-emulsifier is any one or more of polyethers, amine and epoxy condensate;

[0064] 0.15 part of anti-foam...

Embodiment 3

[0076] As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the formula by weight of its raw materials is as follows:

[0077] 95 parts of polyalphaolefin base oil;

[0078] 15 parts of synthetic ester base oil;

[0079] 3 parts of extreme pressure anti-wear agent: the extreme pressure anti-wear agent is any one or more of phosphoric acid esters, phosphorothioate esters, organic borate esters, and sulfurized olefins;

[0080] 3 parts of antioxidants: antioxidants are 4,4-methylenebis 2,6-di-tert-butylphenol, 2,6-di-tert-butyl-p-cresol, 4,4-bisα,α-di Any one or more of methylbenzyldiphenylamine and p-dioctyldiphenylamine;

[0081] 3 parts of rust inhibitor: the rust inhibitor is any one or more of sulfonates, macromolecular carboxylic acids, benzotriazole and its derivatives;

[0082] 3 parts of anti-emulsifier: the anti-emulsifier is any one or more of polyethers, amine and epoxy condensate;

[0083] 0.3 part of anti-foaming ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com