Positioning method and monitoring system for blast furnace tuyere water leakage

A positioning method and tuyere technology, applied in the direction of tuyere, improving energy efficiency, improving process efficiency, etc., can solve problems such as affecting the normal production of blast furnaces, damage to small sets of tuyere, water leakage, affecting the heat balance of hearth, etc., to prevent misjudgment, reduce The effect of artificial and stable furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention provides a technical solution, a method for locating water leakage from a blast furnace tuyere, comprising the following steps:

[0037] A method for locating water leakage at a blast furnace tuyere, comprising the following steps:

[0038] S1: data collection: collect the liquid level data of each tuyere expansion tank of the blast furnace and the liquid level data of the tuyere; collect the hydrogen content in the blast furnace top gas; collect the carbon monoxide and carbon dioxide content in the blast furnace top gas; count the fuel ratio of each shift;

[0039] S2: Data analysis, water leakage judgment:

[0040] Condition 1: The water replenishment period is less than the normal water replenishment period, and the liquid level of the tuyere is lower than the normal range by more than 0.3m;

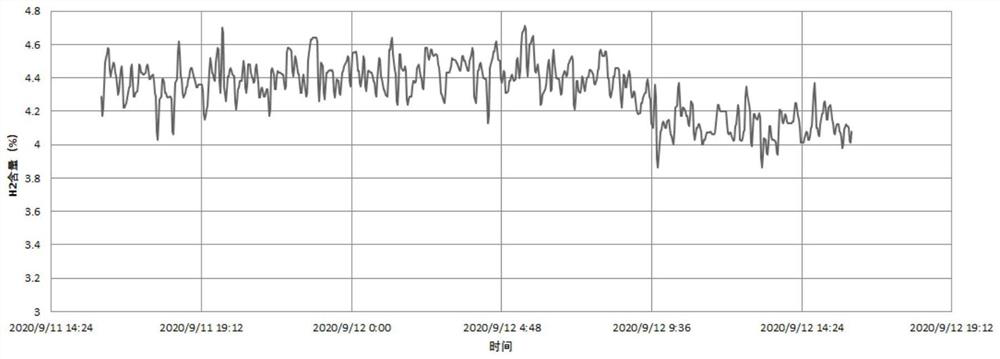

[0041] Condition 2: The hydrogen content in the blast furnace top gas is greater than 4.0%;

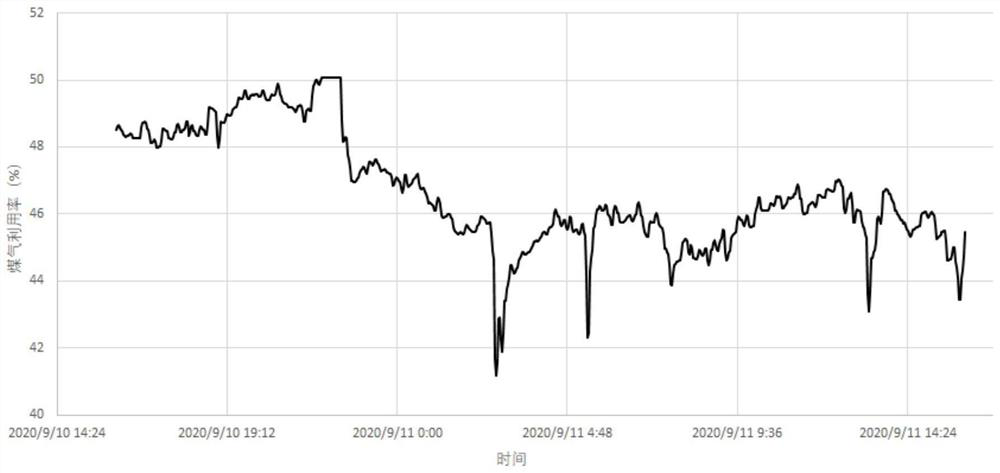

[0042] Condition 3: Gas utilization rate η co Decrease 1%...

Embodiment 2

[0056] A monitoring system for a method for locating water leakage at a blast furnace tuyere, comprising a data acquisition module, a data analysis module and a data display module, the data acquisition module and the data display module are respectively connected with the data analysis module, and the data acquisition module comprises a liquid level gauge, a chromatograph Analyzer, flowmeter and thermocouple temperature sensor, liquid level gauge is installed on the expansion tank and tuyere of the tuyere, the chromatographic analyzer is installed on the top of the blast furnace, the flowmeter is installed on the cooling water inlet and outlet pipes, and the thermocouple temperature sensor is installed on the On the cooling wall of the tuyere, the data display module is used to receive the data of the data analysis module and display it in real time.

[0057] Further, the data analysis module adopts a single-chip microcomputer, and the data display module adopts a display scre...

Embodiment 3

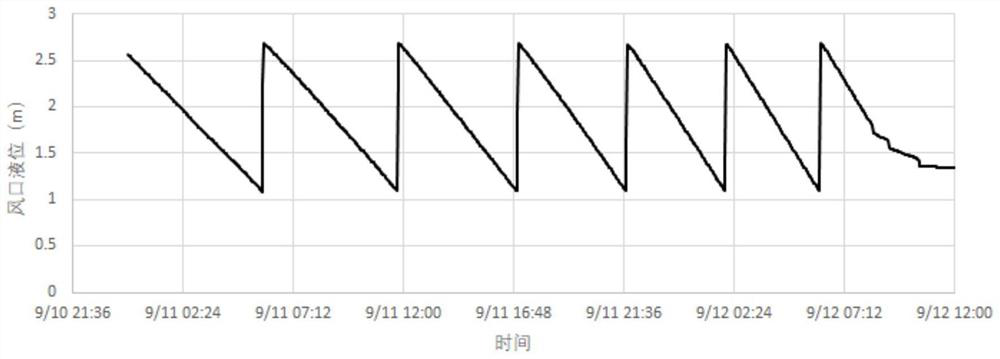

[0059] refer to Figure 1-8, The present invention provides a technical solution. On the basis of Examples 1 and 2, a 5800 blast furnace in Shagang has 40 tuyere. On September 10-12, 2020, the data showed that the following problems occurred: 1. The water replenishment period was shortened ,See figure 1 ; 2. The H2 content of the furnace top is greater than 4%, see figure 2 3. The utilization rate of gas decreases, see image 3 ; 4. Fuel ratio increased, see Figure 4 ; Comprehensively judge the leakage.

[0060] By displaying the data, the flow difference between No. 15 and No. 30 tuyere reaches 10m 3 / h or more, where Figure 5 It is an example of the normal flow difference data map of No. 3 tuyere, Image 6 This is the data map of the flow difference of the No. 15 tuyere, it can be seen that the flow difference of the tuyere reaches 13m 3 / h, at the same time, the on-site inspection found that the No. 15 tuyere had water stains. Through on-site verification, after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com