Seven-layer hollow warm-keeping elastic air layer knitted fabric and preparation method thereof

A knitted fabric and air layer technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of fabric pilling, insufficient hollow warmth, poor pilling, etc. The effect of stretch back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

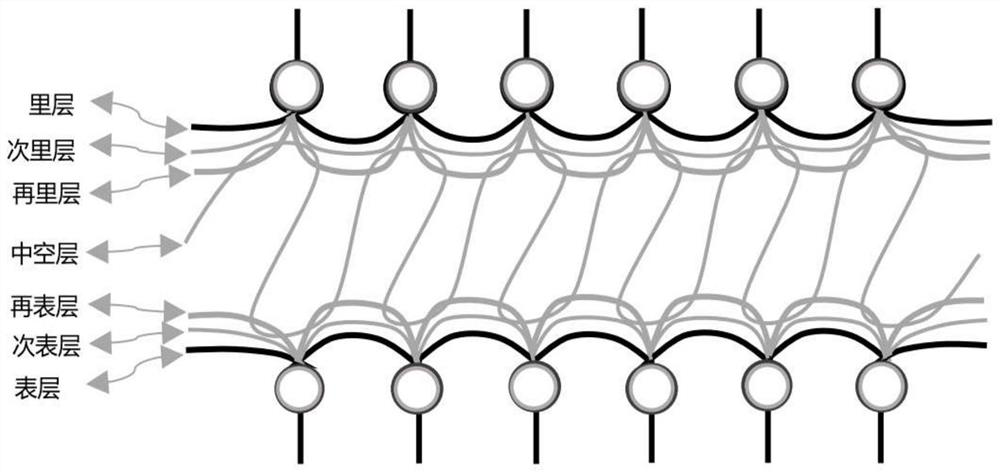

[0074] The present embodiment provides a seven-layer hollow warm-keeping elastic air layer knitted fabric, which is prepared by the following steps:

[0075] (1) Selection of raw materials: 44-inch cotton yarn is selected as the surface layer and inner layer, and the twist is 23.3 TPI; 30D spandex elastic yarn is selected as the sub-surface layer and sub-inner layer; 30D polyester filament is selected as the re-surface layer and re-inner layer; the hollow layer Use 50D polyester filament to connect the upper and lower layers.

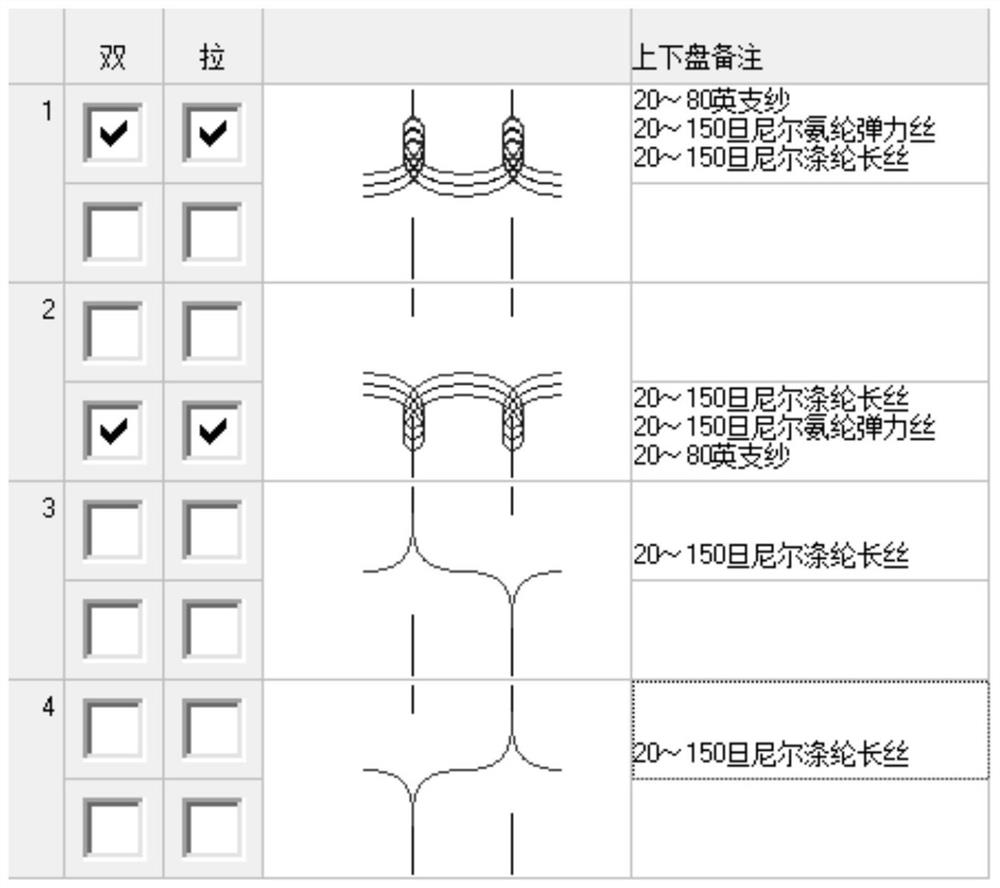

[0076] (2) Four-mode seven-layer weaving is adopted, as shown in the schematic diagram figure 1 and figure 2 As shown, using the above-mentioned double-sided machine, the barrel opening distance of the machine is 2.5-4.0mm, and the needle barrels of 22G33" and 22G34" are used:

[0077] The four-die weaving method forms seven layers, the upper and lower knitting needles are arranged in position, the first die is woven with cotton or cotton cellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com