Surface acoustic wave temperature sensor with locking device

A technology of temperature sensor and locking device, applied in the field of temperature sensor, can solve the problems of inconvenient installation and operation, increased contact resistance of moving and static contacts, scratches, etc., and achieves the effect of simple installation and increased contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

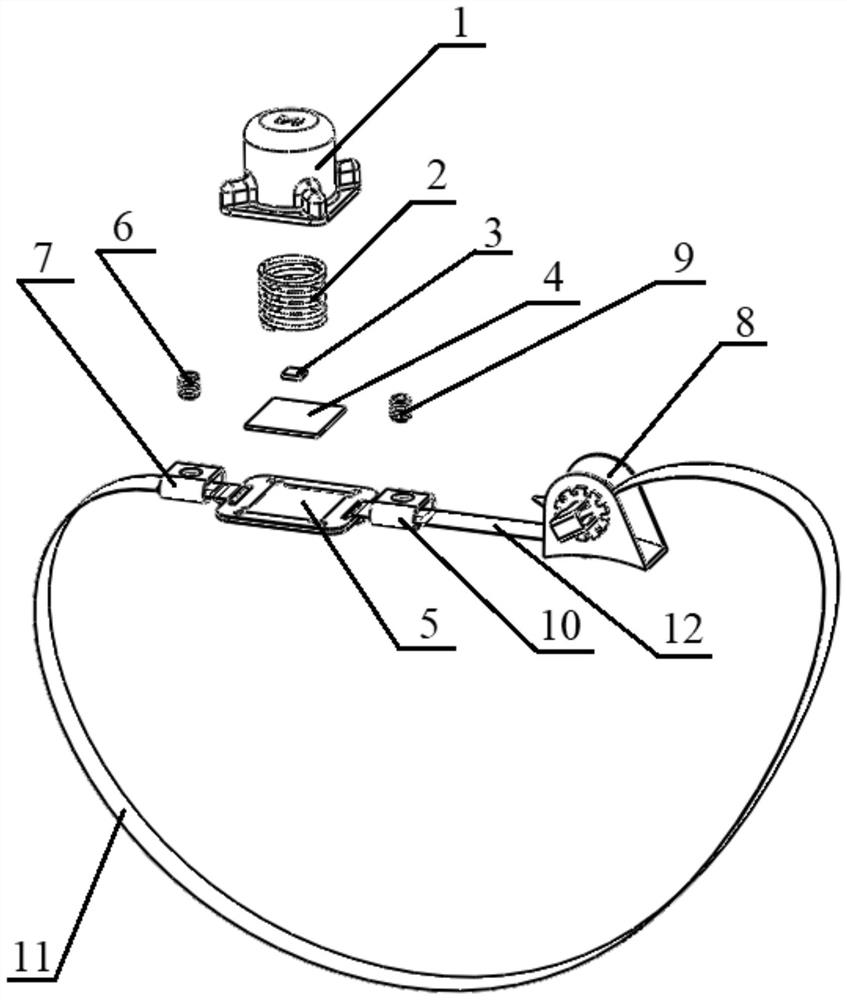

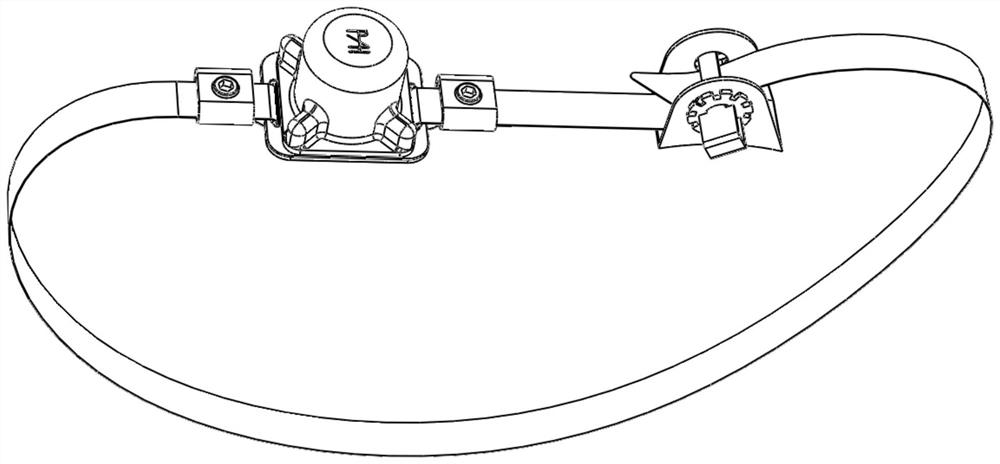

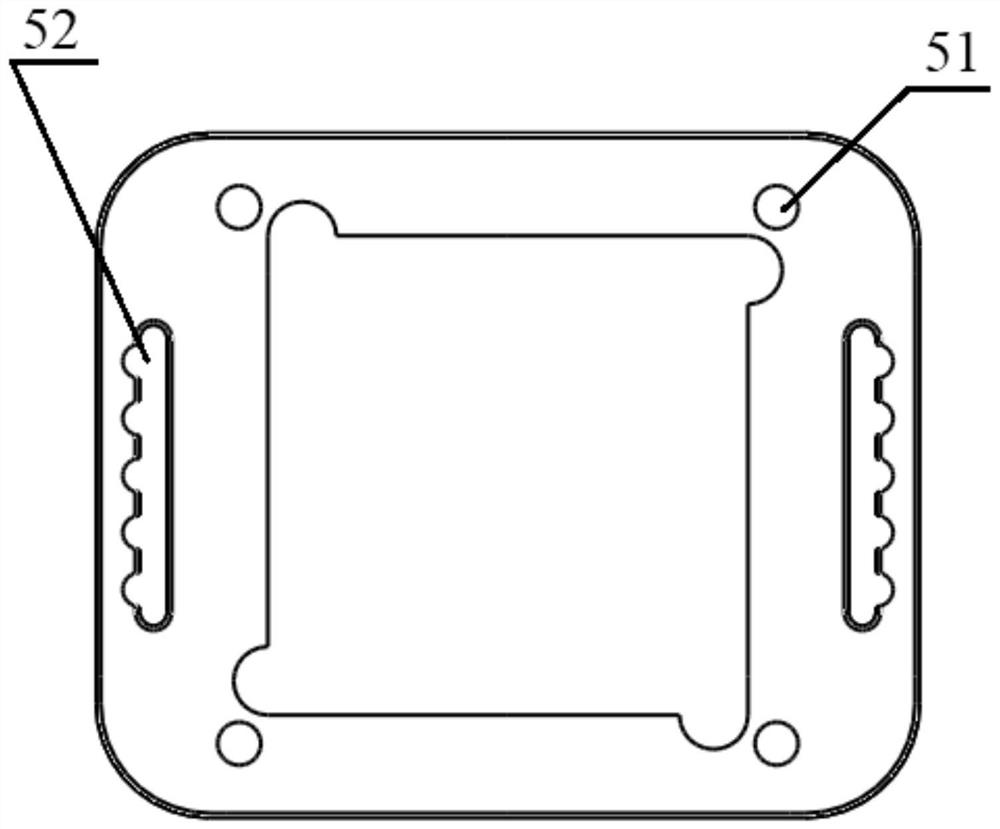

[0038] like figure 1 As shown in -2, the present invention provides a surface acoustic wave temperature sensor with a locking device, comprising a housing 1, a sensor antenna 2, a sensor temperature sensing chip 3, a printed board 4, a metal base plate 5, a first top wire 6, The first through-hole buckle 7 , the locking head 8 , the second top wire 9 , the second through-hole buckle 10 , the first metal tie 11 and the second metal tie 12 .

[0039] The first top wire 6 and the second top wire 9 have the same structure and different installation positions. The first through-hole type buckle 7 and the second through-hole type buckle 10 have the same structure and different installation positions. The first metal tie 11 and the second metal tie 12 have the same structure and different installation positions.

[0040] The sensor temperature sensing chip 3 is a surface acoustic wave (surface acoustic wave, SAW) temperature sensing chip.

[0041] The outer cover 1 is made of insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com