Improved enameled wire production coating equipment and coating method

An enameled wire, an improved technology, applied in the direction of conductor/cable insulation, etc., can solve the problem of low utilization rate of working hours, achieve the effect of ensuring coating effect, not easy to catch fire, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

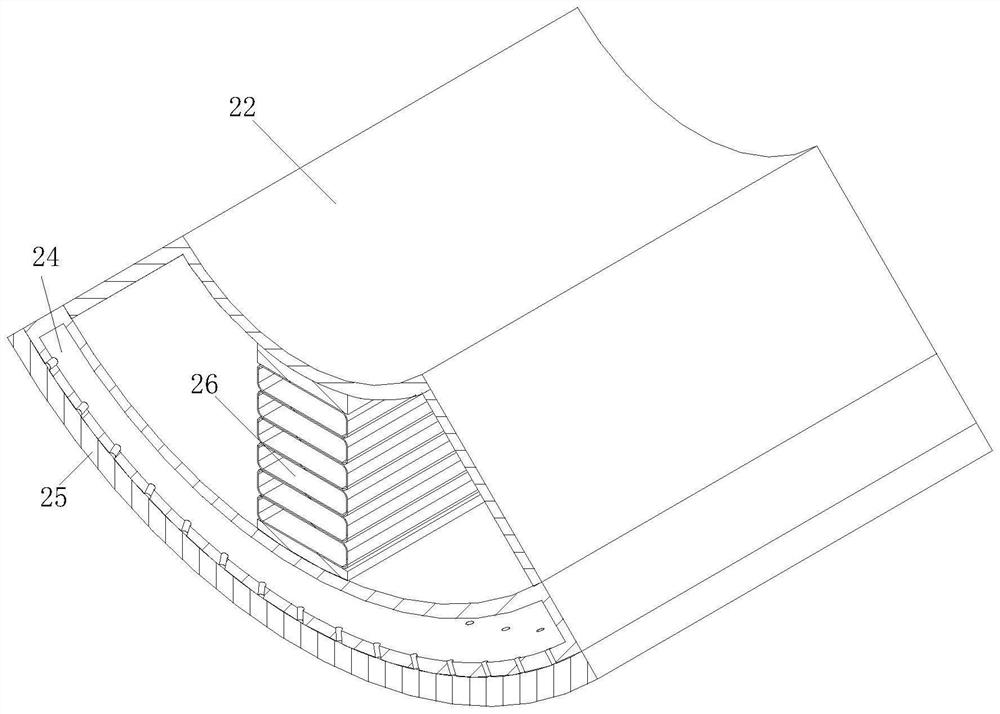

[0053] As an embodiment of the present invention, the coating block 22 includes an airbag 26 fixedly installed inside, the inner circumferential surface of the paint supply box 24 is fixedly connected with the airbag 26, and the airbag 26 is connected to the outer side of the coating equipment through a pipeline. air pump connection;

[0054] while working, such as figure 2 As shown, by setting the air bag 26, when adjusting the paint amount, the controller controls the air pump to supply or pump air to the air bag 26 in the working coating block 22, the air bag 26 expands or contracts, and the air bag 26 expands to supply the paint box 24. Being jacked up, the lacquer box 24 slides on the coating block 22, so that the felt 25 working on the upper shaft 12 and the lower shaft 13 is close, the contact area between the upper and lower felt 25 and the copper wire increases, and the air bag 26 shrinks to supply the lacquer box 24 diameter. To shrink, the felts 25 working on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com