Probe sheet and probe sheet manufacturing method

A probe sheet and flexible sheet technology, which is applied in the field of probe sheet manufacturing, can solve the problems of reduced durability, difficulty in coping with fine pitch, and deterioration of yield, and achieve excellent anisotropy and durability

Pending Publication Date: 2022-08-02

DEXERIALS CORP

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, in the probe sheet described in Patent Document 2, the intermediate layer is also made of an elastic material, and the orientation of the conductive particles also uses a magnetic field. Therefore, the thicker the elastic material layer is, the easier it is for the particles to connect to the adjacent electrodes, and to induce short circuit

Therefore, it is difficult to cope with fine pitch

On the other hand, if the elastic material layer is made thinner, the stroke characteristics will be lowered, and the durability will also be lowered.

In addition, since elastic materials expand and contract due to thermal history, inspection failures due to misalignment may occur

[0007] In addition, in recent years, PKG and semiconductor chips have been increasingly fine-pitched, and the conventional probe sheet has reached its limit.

In addition, the actual situation is that some semiconductor chips are not inspected, but inspection and screening are carried out in the PKG after assembly. As a result, the yield rate is extremely deteriorated, and the price cannot be reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0057]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

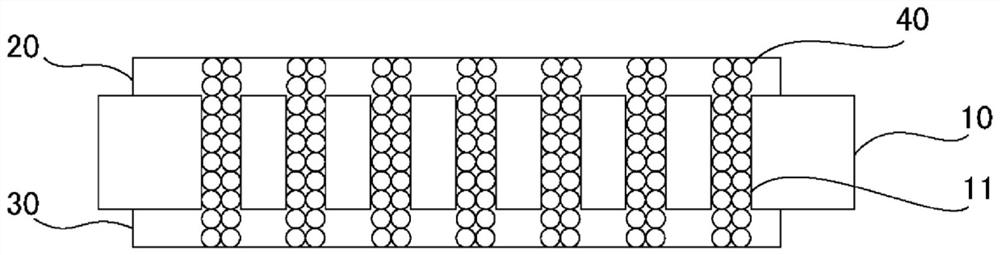

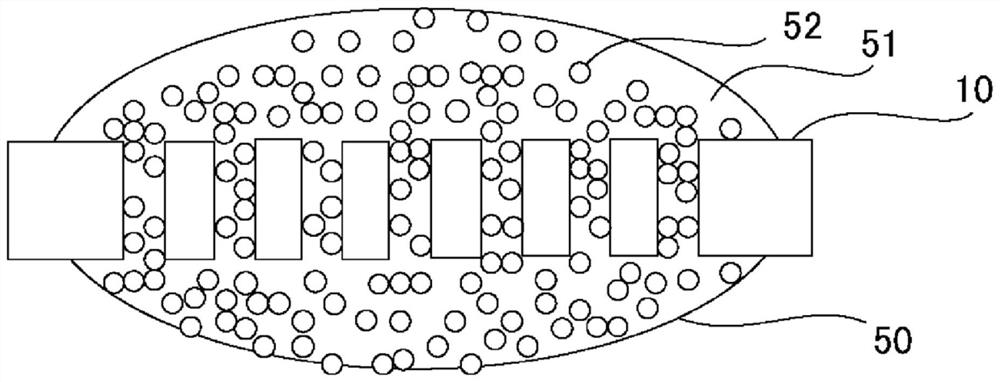

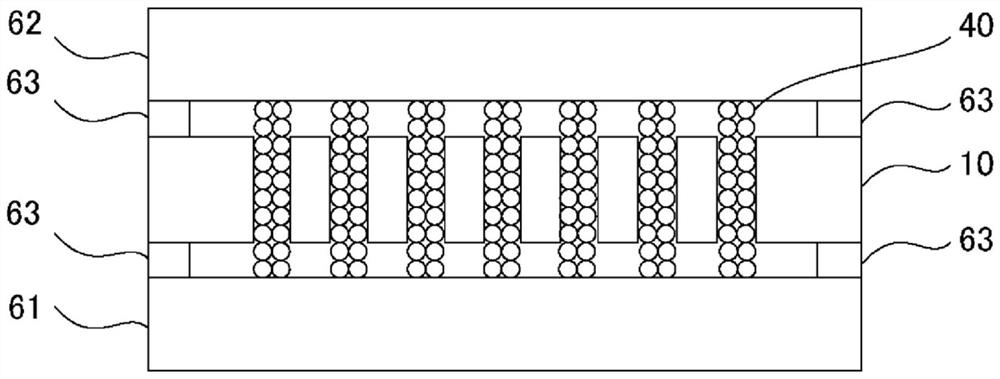

The invention provides a probe sheet and a method for manufacturing the probe sheet, wherein the probe sheet can obtain excellent anisotropy and durability even for terminals with fine pitches. The probe sheet is provided with: a flexible sheet (10) having a plurality of through-holes; a first elastic body layer (20) disposed on one surface of the flexible sheet (10); a second elastic body layer (30) disposed on the other surface of the flexible sheet; and interlocking parts (40) formed by interlocking the conductive particles in the thickness direction from the surface of the first elastic body layer (20) to the surface of the second elastic body layer (30) through the through holes.

Description

technical field [0001] The present technology relates to a probe sheet for inspecting electrical properties of a wafer, a chip, a package, and the like, and a method of manufacturing the probe sheet. This application claims priority based on Japanese Patent Application No. Japanese Patent Application No. 2019-213062 filed in Japan on November 26, 2019, which is incorporated herein by reference. Background technique [0002] At present, a handler test using a rubber connector is performed in the evaluation of electrical characteristics of a bare chip or packaged (PKG) semiconductor device. As a rubber connector used as a probe sheet, for example, an anisotropic conductive sheet in which magnetic field-oriented conductive particles are arranged to penetrate in the thickness direction of the elastic body sheet is proposed (for example, refer to Patent Document 1). [0003] However, for example, in the case of inspecting a BGA (ball grid array) package, the stroke of the probe ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R1/067G01R31/26H01R43/00H01R43/20H01R13/405H01R13/03H01R11/01H01B5/16H01B13/00

CPCH01B5/16H01R11/01H01B13/00H01R43/00G01R31/26G01R1/06761G01R3/00G01R31/2863G01R31/2896

Inventor 石松朋之

Owner DEXERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com