High-molecular separation membrane with high toughness and preparation method thereof

A polymer and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as easy rupture, and achieve the effect of not easy to rupture, increase toughness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

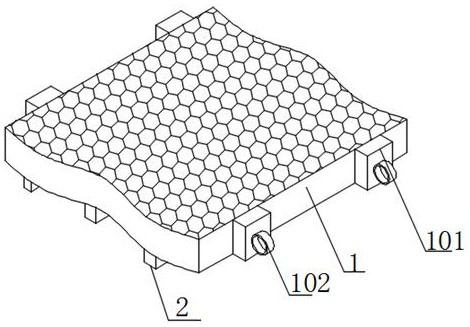

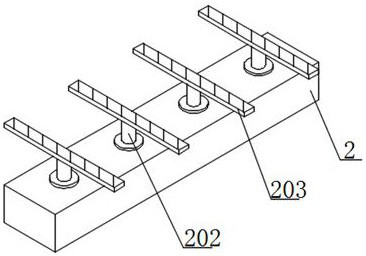

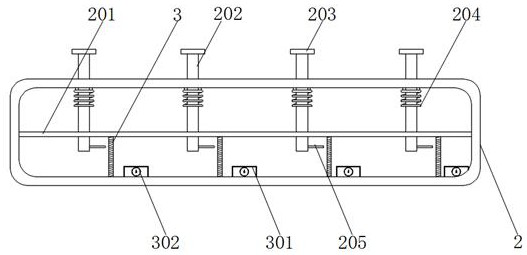

[0036] Embodiment 1: an embodiment provided by the present invention: a high toughness polymer separation membrane and a preparation method thereof, comprising a main body 1 and an auxiliary block 2, the outer wall of the main body 1 is installed with a fixing plate 101, and the outer wall of the fixing plate 101 is installed A connecting ring 102 is installed, an auxiliary block 2 is installed at the bottom of the main body 1, a support plate 201 is installed on the inner wall of the auxiliary block 2, a support rod 202 is installed through the top of the support plate 201, and the top of the support rod 202 extends out of the auxiliary block 2 The top of the support rod 202 is installed with a bonding plate 203, the outer wall of the support rod 202 is surrounded by a spring 204, the outer wall of the support rod 202 is installed with a conductive rod 205, and the bottom of the support plate 201 is installed with a detection resistor 3. A filter layer 7 is installed on the in...

Embodiment 2

[0045] Example 2: First, prepare 15 parts of polyethersulfone, 10 parts of oleophobic group-modified nano-mesoporous silica, and 150-200 parts of N,N dimethylformamide solvent;

[0046] First, the mesoporous silica and polyethersulfone modified with oleophobic groups are placed in a mixer for stirring, and the heating temperature is controlled to be 100-150 °C. Uniform solution, and then use the coating equipment to coat the substrate (glass, non-woven fabric, etc.) into a film with uniform thickness, and then put it into the coagulation bath for 10-24 hours for curing, and then take out the cured material and use Cutting device cuts solid material into 4×4cm squares

Embodiment 3

[0047] Example 3: First prepare 20 parts of polyethersulfone, 20 parts of oleophobic group-modified nano-mesoporous silica, and 150-200 parts of N,N dimethylformamide solvent;

[0048] First, the mesoporous silica and polyethersulfone modified with oleophobic groups are placed in a mixer for stirring, and the heating temperature is controlled to be 100-150 °C. Uniform solution, and then use the coating equipment to coat the substrate (glass, non-woven fabric, etc.) into a film with uniform thickness, and then put it into the coagulation bath for 10-24 hours for curing, and then take out the cured material and use Cutting device cuts solid material into 4×4cm squares

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com