Heating coordination mechanism for efficient dust removal

A high-efficiency, dust-removing box technology, applied in the direction of electrostatic effect separation, cleaning methods and appliances, cleaning methods using tools, etc., can solve the problems of insufficient gas contact area, insufficient gas heating effect, and reduced post-stage dust removal effect, etc., to achieve Reduces pressure, guarantees anti-corrosion protection effect, reduces impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

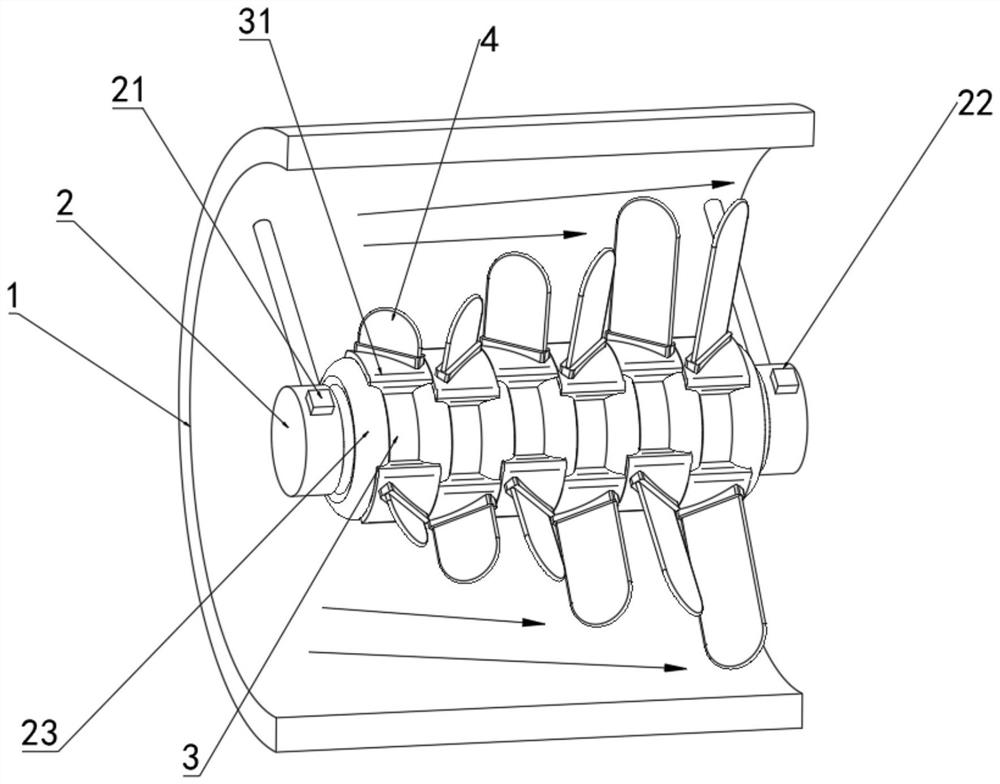

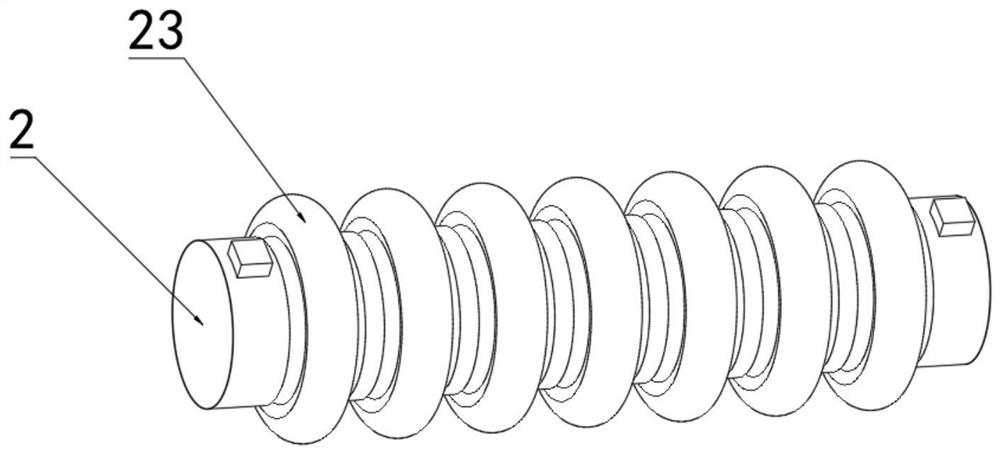

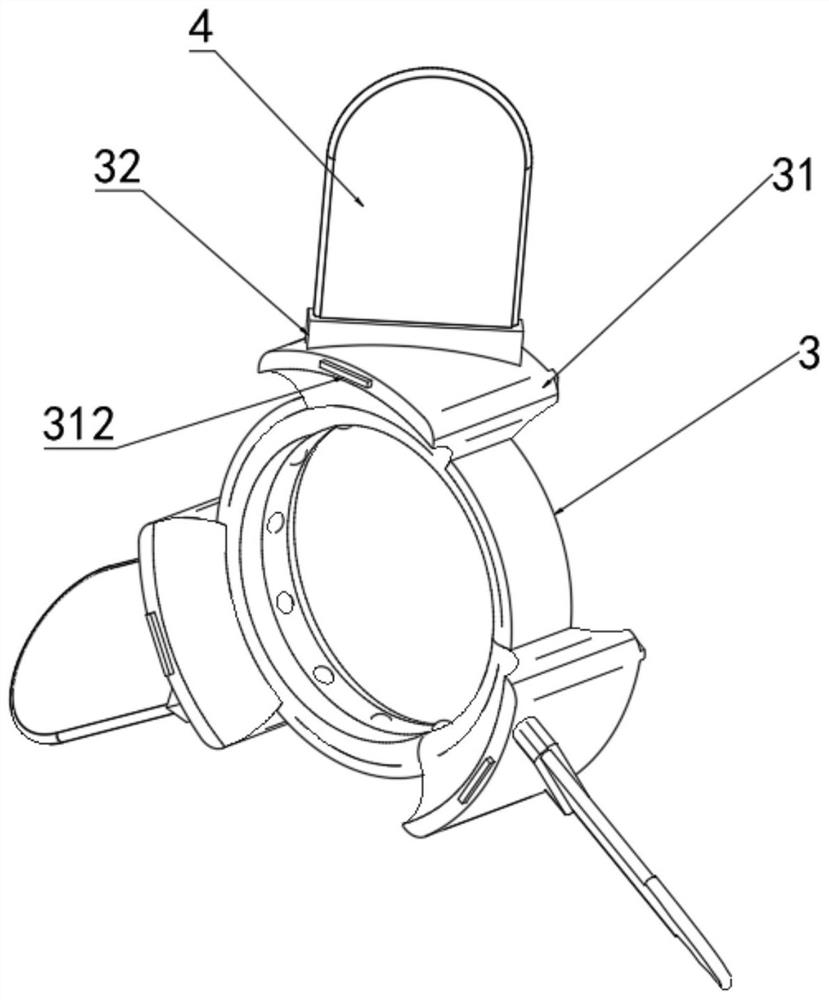

[0028] refer to Figure 1-8 , a heating coordination mechanism for high-efficiency dust removal, including a flue gas flow channel 1, an electric heater 2 is fixedly installed at the inner center of the flue gas flow channel 1 through a plurality of sets of fixed shafts, and the outer fixed sleeve of the electric heater 2 is connected with a ring-shaped Porcelain sleeve 23, the outer side wall of the electric heater 2 is located at both ends of the annular porcelain sleeve 23, and a first temperature measuring device 21 and a second temperature measuring device 22 are respectively fixedly installed. A sliding ring 3 is provided. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com