Automatic casting system for aluminum piston

A piston, automatic technology, applied in foundry, casting equipment, manufacturing tools, etc., can solve problems such as limited automation, manual participation, and no piston ring blank processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

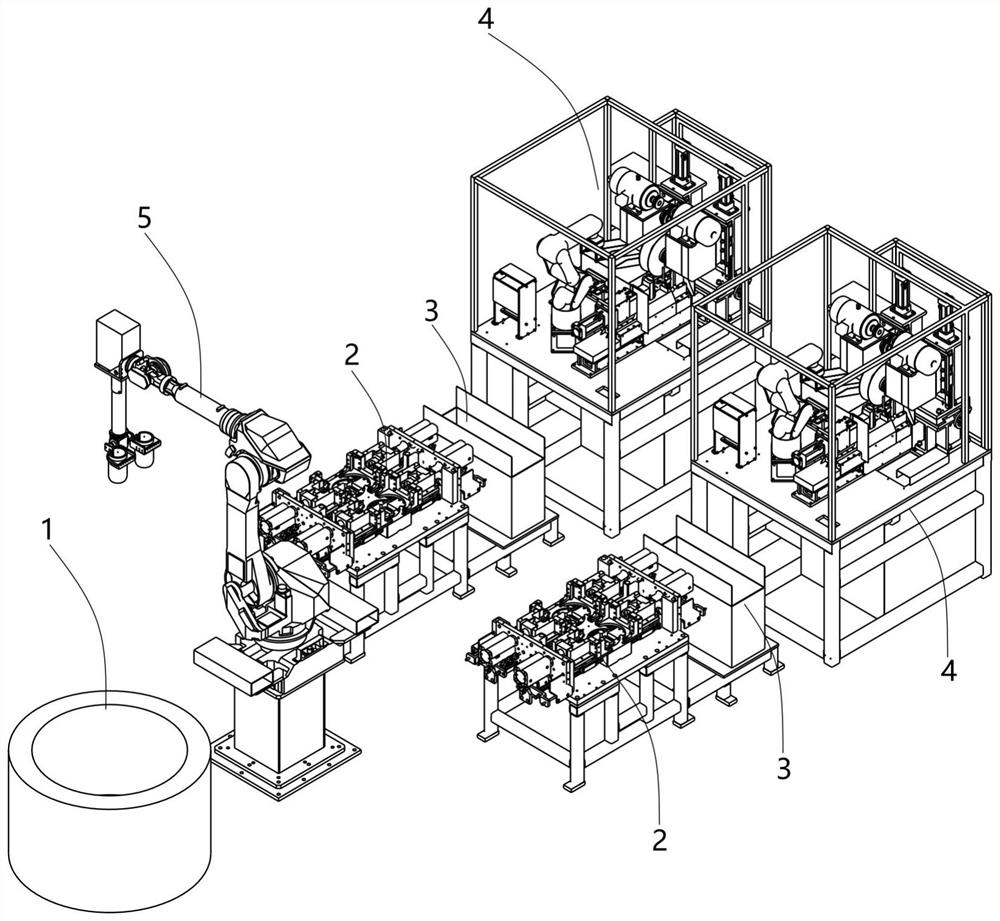

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. In this specification, the size ratio of the drawings does not represent the actual size ratio, but is only used to reflect the relative positional relationship and connection relationship between the components, and the names are the same Or identically numbered components represent similar or identical structures and are for illustrative purposes only.

[0026] Here, some terms in this application are first introduced.

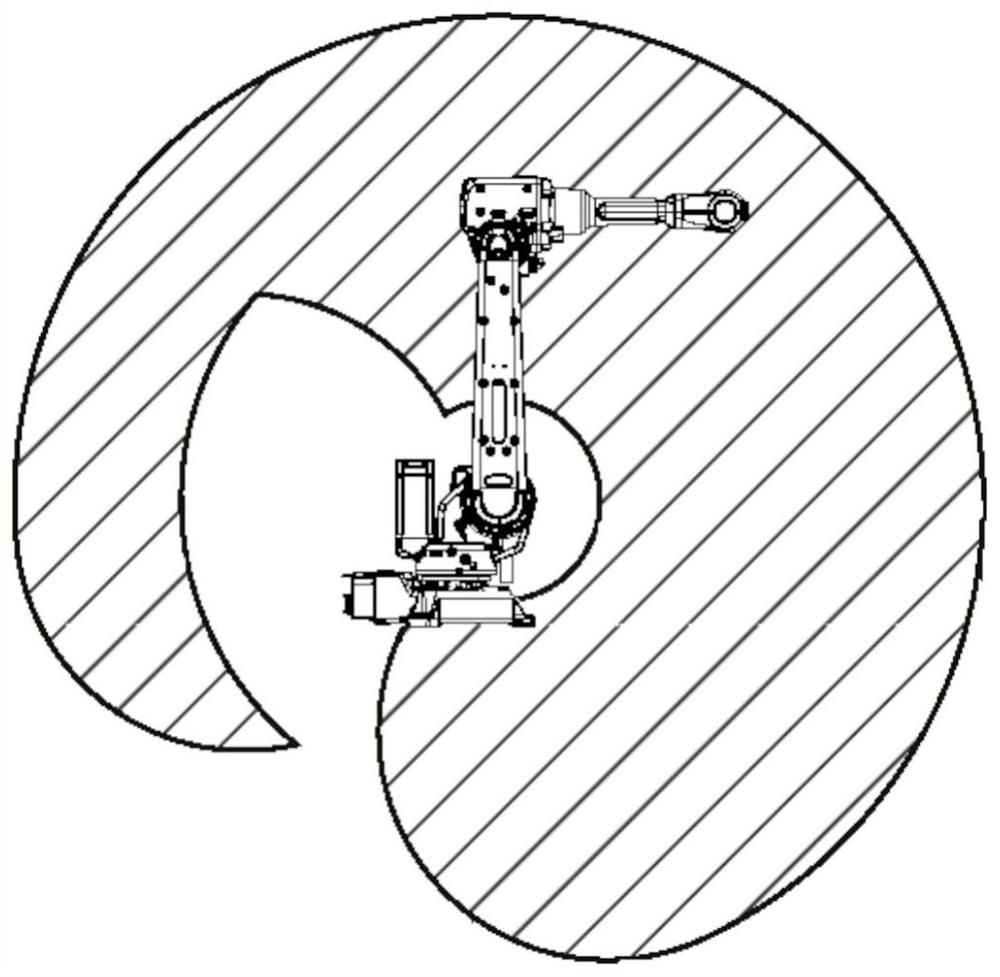

[0027] Robot end: For the multi-axis serial manipulator type robot used in this application, one end is the robot base, which is fixed on the mounting seat 524, and the other end is the power head, which installs the working parts that perform functions. Under the multi-axis coordinated motion Realize the movement of work parts in three-dimensional space. The robot end 56 in the present application refers to the side of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com