Intelligent polishing machine for filter production based on mobile internet

A mobile interconnection and filter technology, applied in the field of polishing machines, can solve the problems of single polishing function, inability to achieve polishing, and synchronization of polishing degree, etc., and achieve the effect of high degree of intelligence, convenient and detachable settings, and accurate polishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

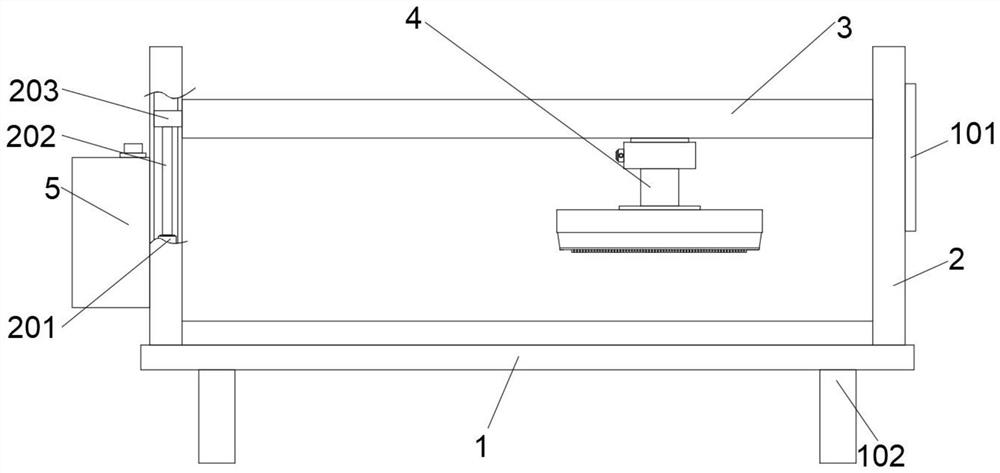

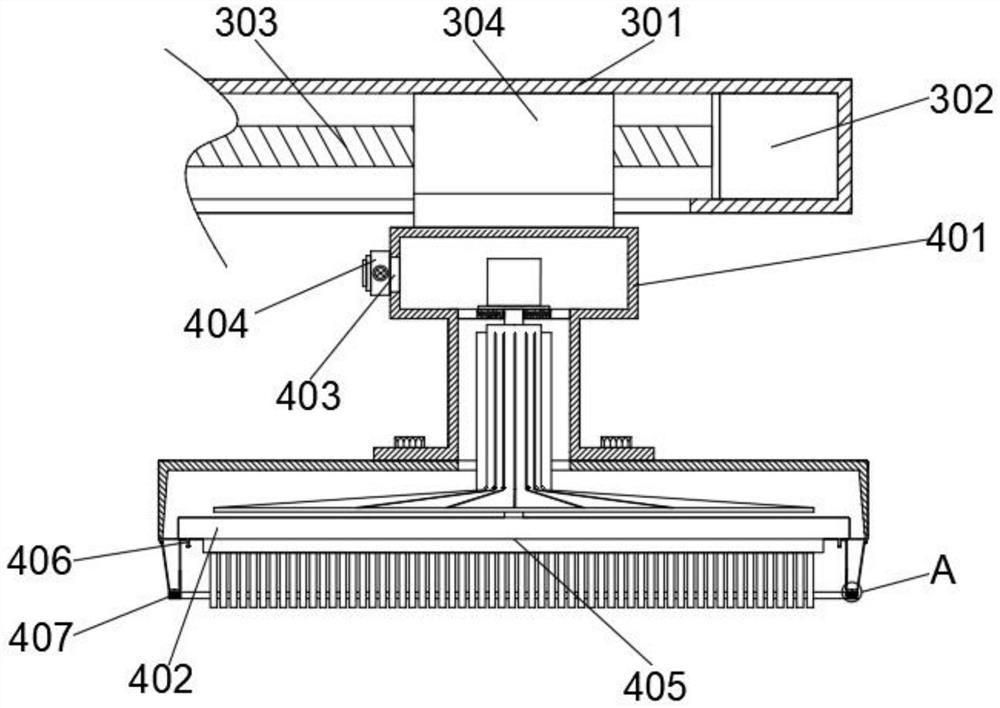

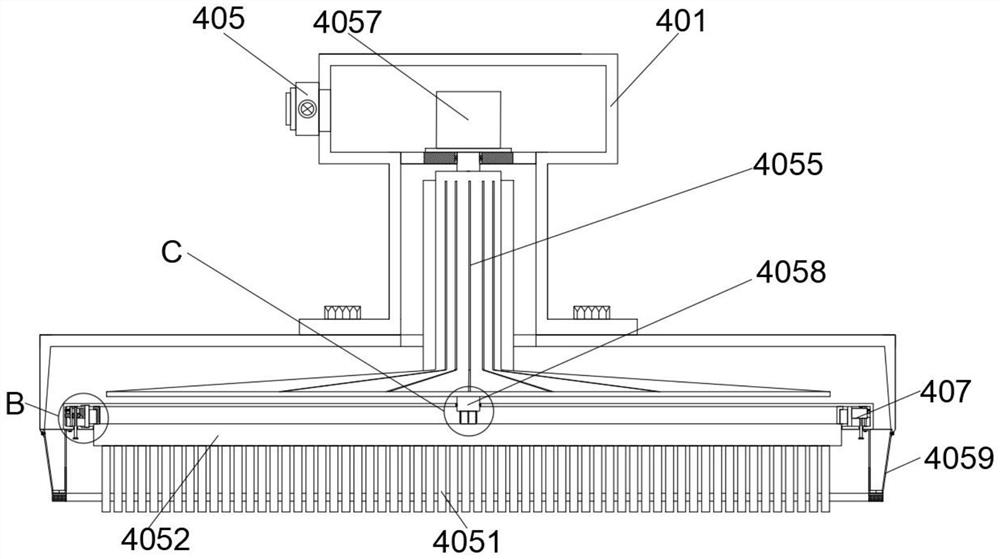

[0030] like Figure 1-Figure 6 As shown, a polishing machine for filter production based on mobile internet intelligence is connected to a control panel 101 based on a network signal, and includes a workbench 1, a lifting frame 2, a control panel 101 and a base 102, and the base 102 is fixed on the workbench 1. At the four corners, the lifting frame 2 is fixed on the top of the worktable 1, and two lifting frames 2 are symmetrically arranged. A driving assembly 3 is slidably arranged between the lifting frame 2 components, and a polishing and dust removal detection body is installed on the driving assembly 3. 4. The polishing and dust removal detection body 4 includes a T-shaped box body 401 and a snap ring shell 402. The top side wall of the T-shaped box body 401 is provided with a dust outlet 403, and a gas quality detector 404 is fixedly installed at the dust outlet 403. , the gas quality detector 404 is connected through the T-shaped box 401,

[0031]The snap ring shell 4...

Embodiment 2

[0047] In the first embodiment of the present invention, a polishing machine for filter production based on mobile internet intelligence is proposed, which realizes intelligent polishing, but there are still some shortcomings in this process, because the polishing strip 4051 directly interacts with the filter during polishing. Strong friction is carried out, so that the polishing strip 4051 is easily damaged and dropped, which reduces the degree and accuracy of intelligent polishing. Therefore, in this embodiment, the polishing plate 4052 on which the polishing strip 4051 is installed is set to be detachable, which is convenient for replacing the polishing strip 4051;

[0048] like figure 1 , Figure 7 and Figure 8 As shown, the snap ring shell 402 is provided with snap assemblies 407 for snapping the polishing plate 4052 and making it detachable. There are at least three snap assemblies 407, and the snap assemblies 407 are centered on the snap ring shell 402. The center is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com