Oil-resistant and low-temperature-resistant rubber material as well as preparation method and application thereof

A technology of rubber materials and low temperature resistance, applied in the field of oil resistant rubber materials, can solve the problem that rubber sealing rings cannot have excellent oil resistance and low temperature resistance at the same time, achieve excellent oil resistance, improve low temperature resistance, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

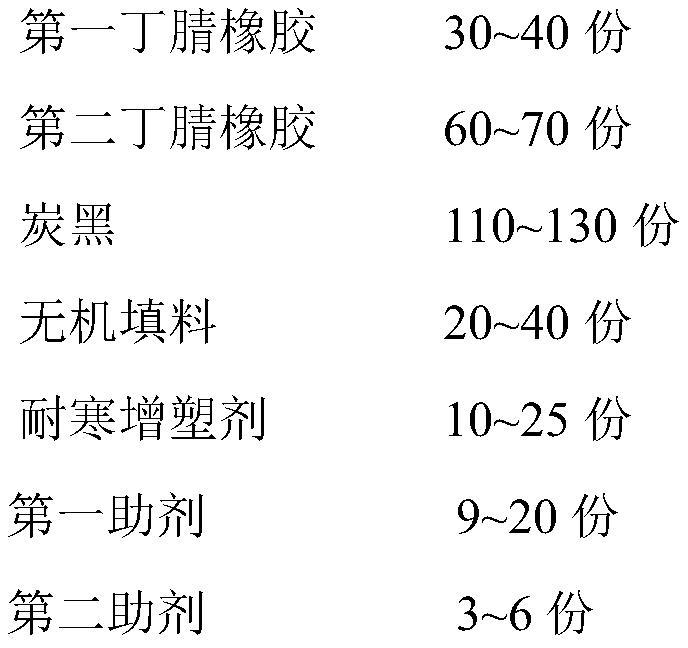

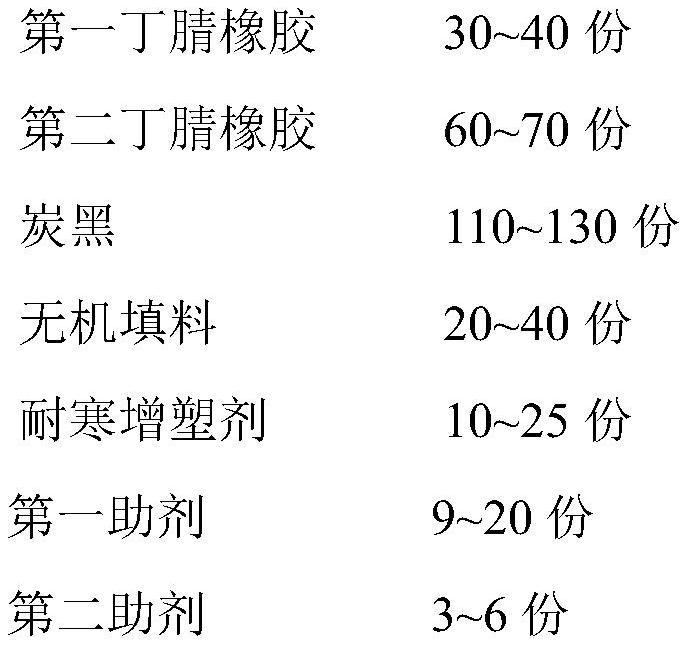

Method used

Image

Examples

Embodiment 1

[0074] Example 1 Preparation of oil-resistant and low-temperature-resistant multifunctional rubber sealing ring

[0075] S1. Calculated in parts by weight, the first nitrile rubber (content of acrylonitrile is 35%) 35 parts, the second nitrile rubber (content of acrylonitrile is 26%) 65 parts, zinc oxide 5 parts, stearin 1.5 parts of acid, 2 parts of saturated fatty acid ester dispersant, 1 part of protective wax, 2 parts of ketone amine antioxidant, 2 parts of p-phenylenediamine antioxidant were put into a 75L internal mixer for mixing, and then added after pressing the top bolt for 40s Quickly press 65 parts of furnace black and 53 parts of semi-reinforced furnace black for kneading, press the top bolt for 100s, add 30 parts of inorganic filler and 15 parts of cold-resistant plasticizer and knead, press the top bolt for 100s, and then raise the top Clean the bolt, press the top bolt to continue mixing, press the top bolt for 130s, and then heat to 150 °C to obtain the master...

Embodiment 2

[0077] Example 2 Preparation of oil-resistant and low-temperature-resistant multifunctional rubber sealing ring

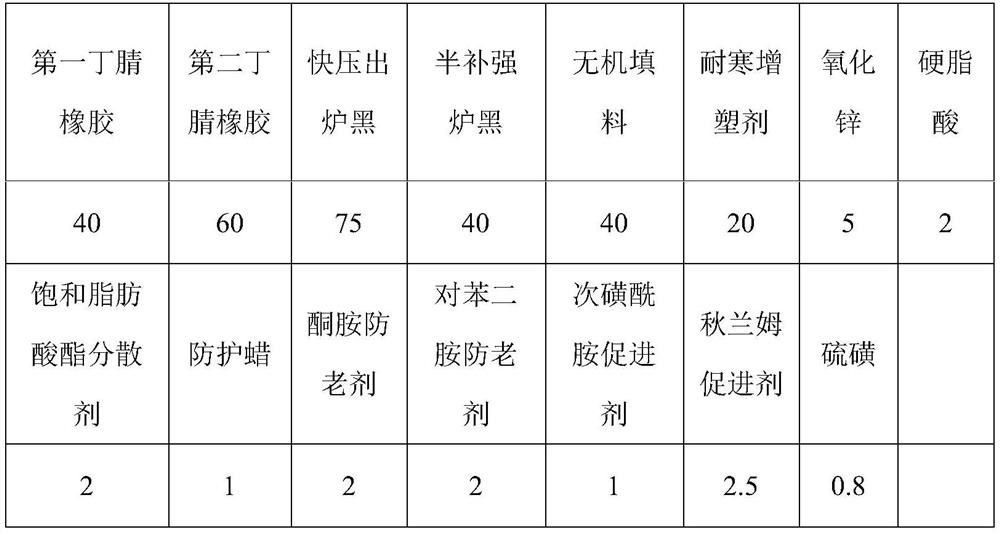

[0078] The difference with Example 1 is that the content of acrylonitrile in the first nitrile-butadiene rubber is 34%, the content of acrylonitrile in the second nitrile-butadiene rubber is 26%, and the addition amount of each component is different, and the specific addition amount is shown in Table 1. As shown, the conditions of the remaining steps are the same as those in Example 1.

[0079] Table 1: The addition amount of each component in Example 2 (calculated in parts by weight)

[0080]

Embodiment 3

[0081] Example 3 Preparation of oil-resistant and low-temperature-resistant multifunctional rubber sealing ring

[0082] The difference from Example 1 is that the content of acrylonitrile in the first nitrile-butadiene rubber is 32%, the content of acrylonitrile in the second nitrile-butadiene rubber is 29%, and the addition amount of each component is different, and the specific addition amount is shown in Table 2 As shown, the conditions of the remaining steps are the same as those in Example 1.

[0083] Table 2: The addition amount of each component in Example 3 (calculated in parts by weight)

[0084]

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com