Additive manufacturing online detection device and method based on transmission-type laser ultrasound

A laser ultrasonic and additive manufacturing technology, applied in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, solids analysis using sonic/ultrasonic/infrasonic waves, etc. It can solve the problem of signal instability, low ultrasonic energy, and buried defect detection. Insufficient capacity and other problems to avoid interference, avoid insufficient detection capacity, and solve insufficient ultrasonic coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

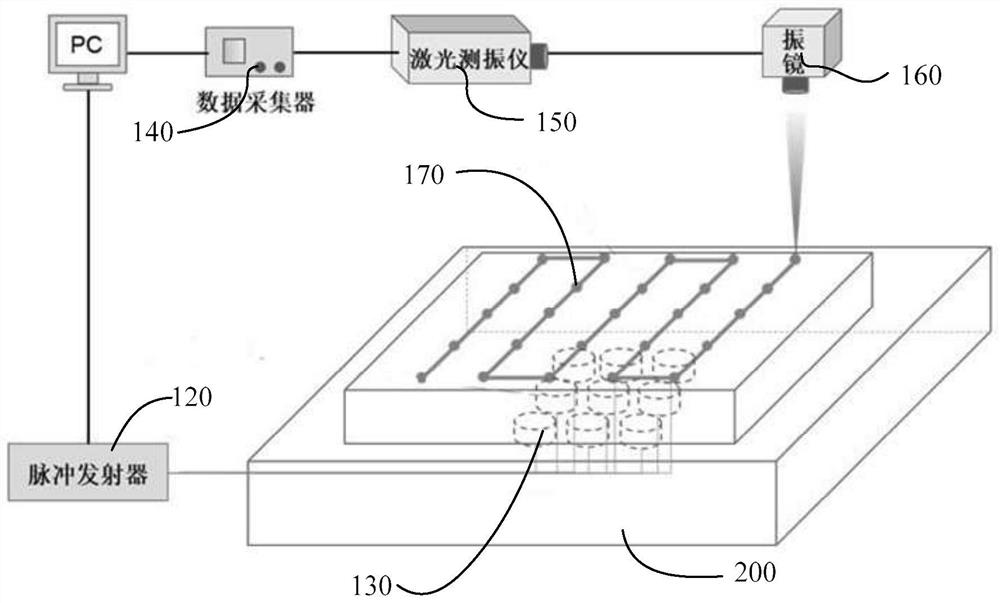

[0041] refer to figure 1 and figure 2 , this embodiment provides an online detection device for additive manufacturing based on transmissive laser ultrasound, including: an ultrasonic excitation module, a laser ultrasonic receiving module, a data acquisition and imaging module; the above-mentioned ultrasonic excitation module includes a piezoelectric sensor 130 and a pulse transmitter 120 The above-mentioned laser ultrasonic receiving module includes a laser vibrometer 150 , an optical head and a scanning galvanometer 160 ; the above-mentioned data acquisition and imaging module includes a motion control card and a data acquisition card 140 .

[0042]The above-mentioned piezoelectric sensor 130 is placed on the back of the substrate 200 to excite the ultrasonic signal, and the above-mentioned pulse transmitter 120 is used to connect the piezoelectric sensor 130 to transmit a pulse signal; the above-mentioned laser vibrometer 150 is used to connect the optical head to emit a d...

Embodiment 2

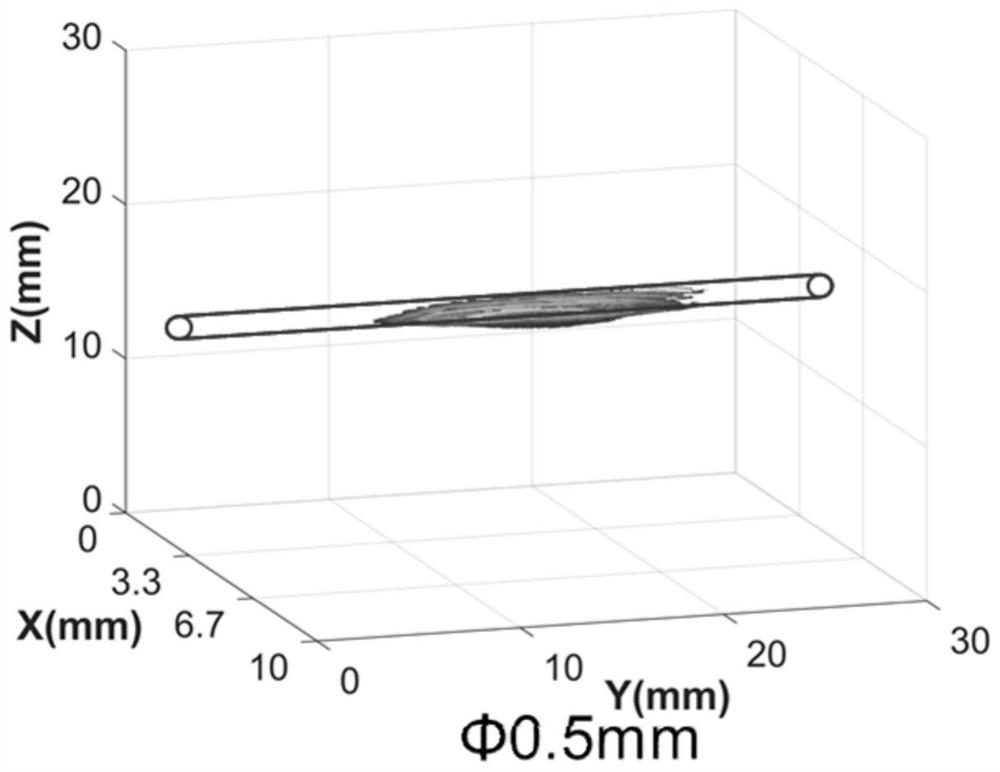

[0046] refer to Figure 3-7 , select the 316L stainless steel sample printed by laser cladding, and set through hole defects of different sizes inside, and the defect sizes are The depth is 15mm.

[0047] This embodiment provides an on-line detection method for additive manufacturing based on transmissive laser ultrasound, which is implemented by the on-line detection device for additive manufacturing based on transmissive laser ultrasound provided in Embodiment 1. The method includes the following steps:

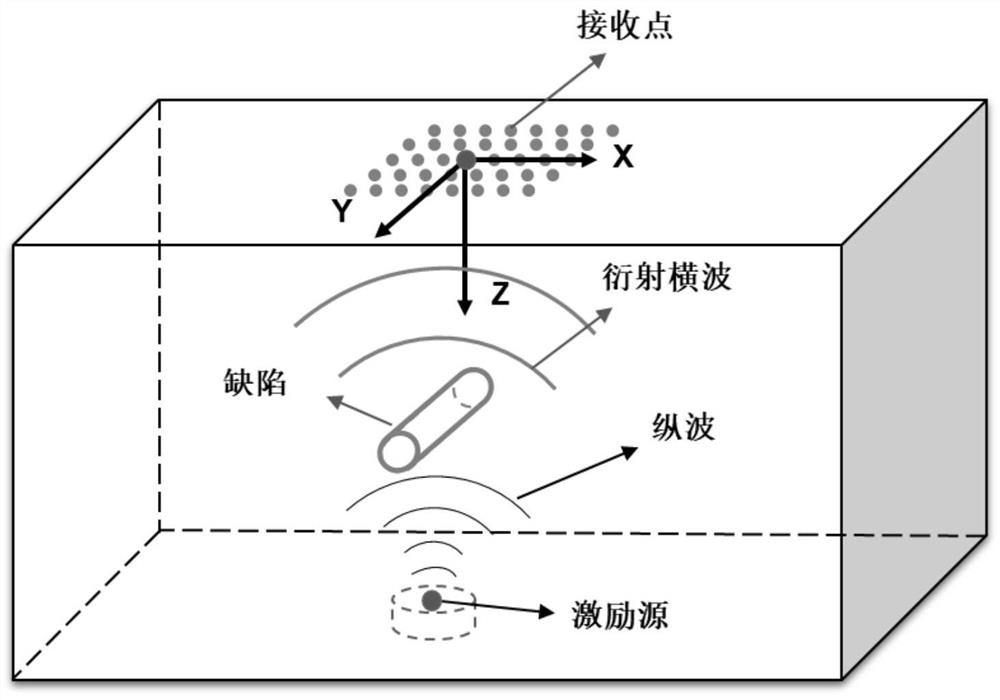

[0048] S1. Array probe excitation and data collection received by array scanning: Five piezoelectric sensors 130 are set on the back of the substrate 200, and the ultrasonic waves are excited in sequence directly under each defect; the center of the array corresponding to the surface of the printed part on the opposite side is set as At the center of the array scanning and receiving, the spot of the detection laser is scanned and received by N*N in the horizontal direct...

Embodiment 3

[0053] refer to Figure 8-12 , select the 316L stainless steel sample printed by laser cladding, and set through hole defects of different depths inside, and the defect size is The defect depths are: 5mm, 10mm, 15mm, 20mm, 25mm.

[0054] It is realized by adopting the online detection device for additive manufacturing based on transmission type laser ultrasound provided in Example 1, and the above method includes the following steps:

[0055] S1. Array probe excitation and data collection received by array scanning: Five piezoelectric sensors 130 are set on the back of the substrate 200, and the ultrasonic waves are excited in sequence directly under each defect; the center of the array corresponding to the surface of the printed part on the opposite side is set as At the center of the array scanning and receiving, the spot of the detection laser is scanned and received by N*N in the horizontal direction, and the scanning distance is 0.4mm, so that each piezoelectric sensor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com