Pellet multifunctional ore blending model building method

A kind of pelletizing and multi-functional technology, applied in the field of sintering pellets, can solve problems such as the error between theoretical composition value and actual value of pellets, poor adaptability of pelletizing model, etc., to improve comprehensiveness and accuracy, improve Accuracy, the effect of increasing the analysis function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] 1. Calculate the oxidation reaction weight gain rate of FeO content in magnetite concentrate. FeO oxidation reaction formula:

[0100] 2FeO+O 2 ↑=Fe 2 O 3

144 16 160

[0101]The oxidation of FeO content in magnetite is a weight gain process, and the FeO weight gain rate=16÷144×100%=11.1%.

[0102] 2. Open the EXCEL sheet.

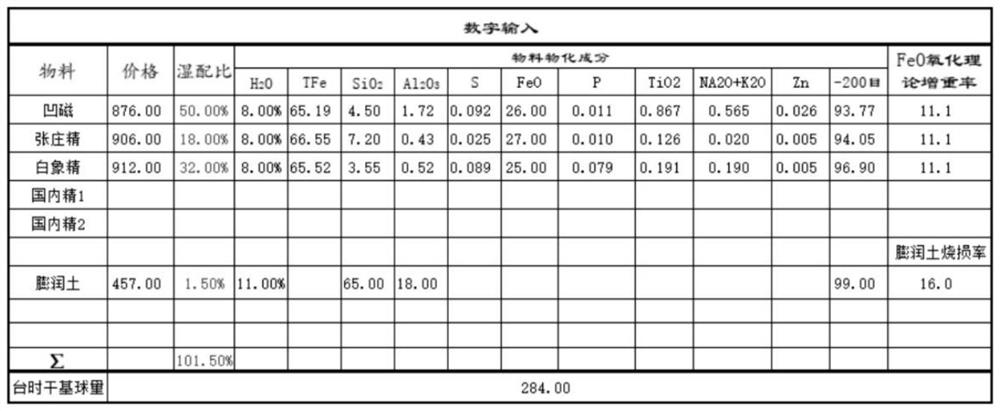

[0103] 3. As figure 1 Enter the wet ratio of raw materials, physical and chemical indicators of raw materials, unit price, FeO weight gain rate (11.11%), bentonite burning loss value (generally set to be about 16%), and the amount of dry-base pellets at table time. The main physical and chemical indicators of raw materials are: H 2 O, TFe, SiO 2 , Al 2 O 3 , S, FeO, P, TiO 2 , Na 2 O+K 2 O, Zn, -200 mesh ratio, etc.

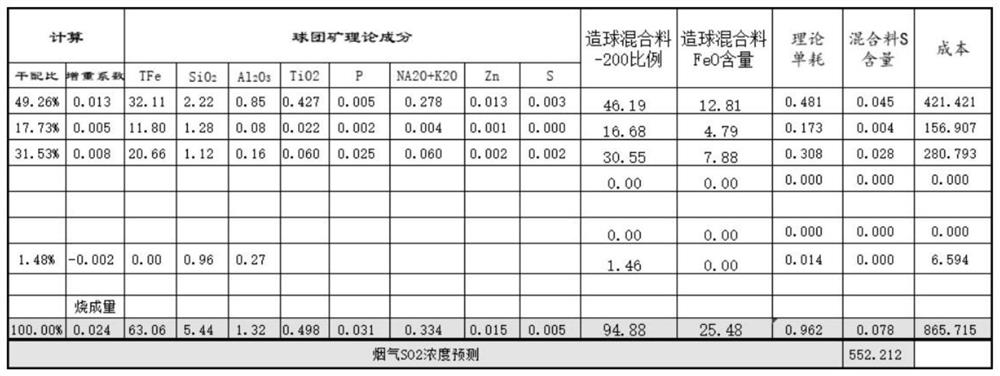

[0104] 4. As figure 2 As shown, set the output item formula of each batching model in the EXCEL table

[0105] 4.1 In the EXCEL table, set the formula for converting the wet base ratio of each raw material to the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com