Lead-acid storage battery substrate curing equipment

A technology of lead-acid batteries and curing equipment, which is applied in the construction of lead-acid batteries, lead-acid batteries, electrodes of lead-acid batteries, etc., and can solve problems such as uneven curing effects of plates, increased differences, and temperature and humidity differences in curing boxes. , to achieve the effects of improving temperature and humidity stability, speeding up exchange and circulation, and improving stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

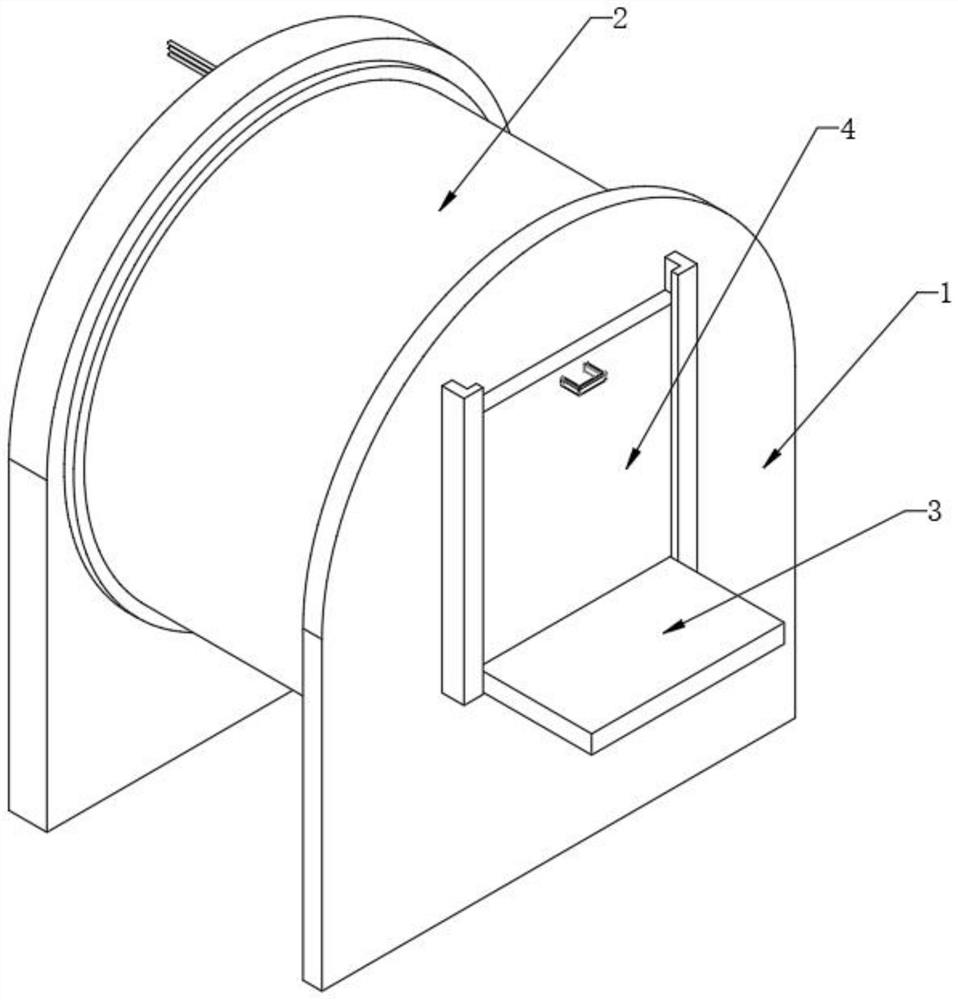

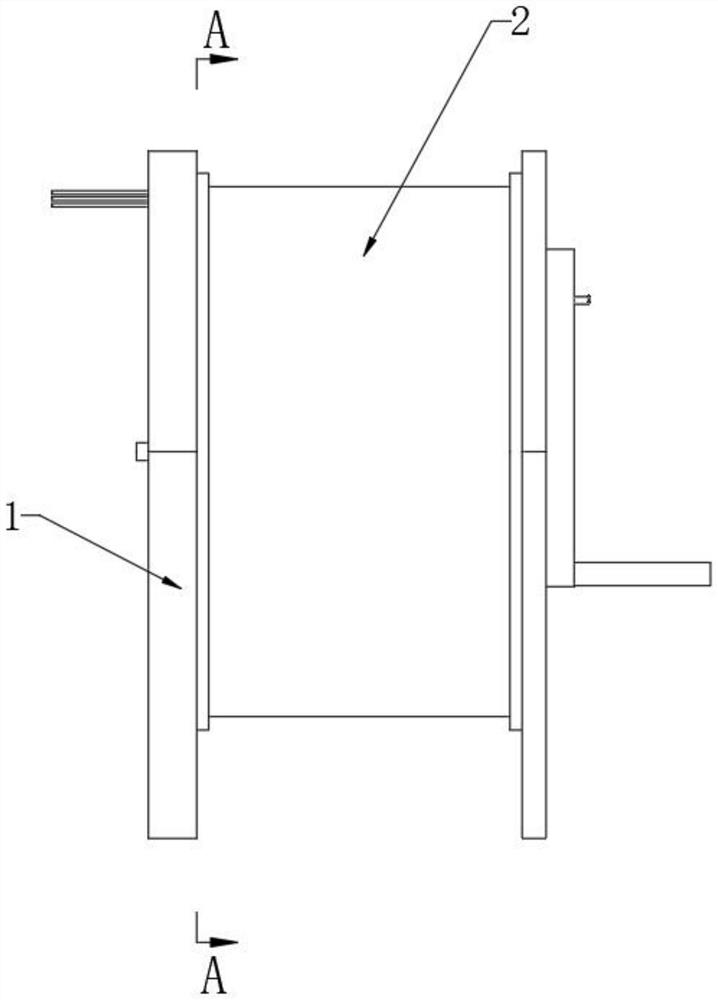

[0029] see Figure 1 to Figure 9 , the present invention provides a technical solution: a lead-acid battery substrate curing equipment, comprising two vertical plates 1, a rotating drum 2 is installed between the two vertical plates 1, and one of the vertical plates located in the rotating drum 2 1. A grid plate 3 for placing battery pole plates is installed on the outer wall, and also includes a temperature adjustment component for supplying heat, humidity and air discharge into the rotating drum 2.

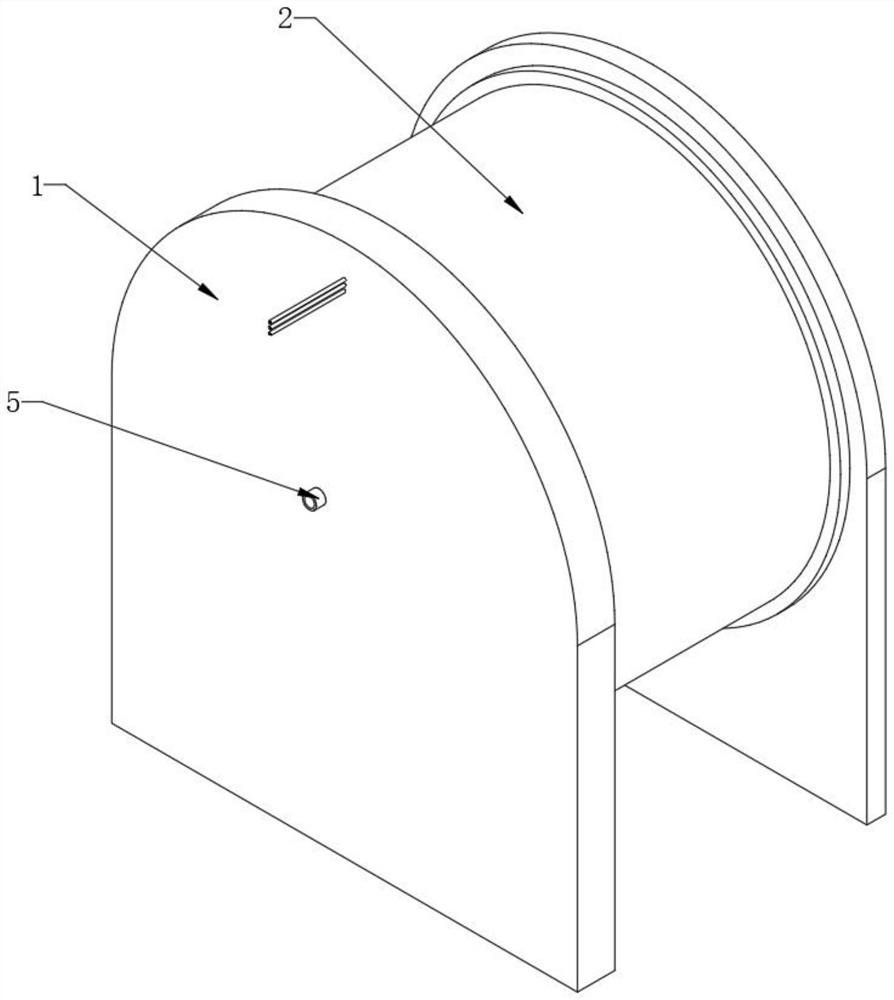

[0030] Another vertical plate 1 located in the drum 2 is provided with a hole on the outer wall, and a rotatable rotating tube 5 is installed in the hole. One end extending into the drum 2 is fixed with a piston tube 6, the inner wall of the piston tube 6 is slidably mounted with a piston block 13, the inner wall of the piston block 13 is provided with a hole, and a piston rod 7 is fixed in the hole, and both ends of the piston rod 7 Passing out of the outer wall of the piston ...

Embodiment 2

[0051] Embodiment 2 provides a second embodiment of the drive assembly;

[0052] Further, the drive assembly includes a pulley 22 fixed on the outer wall of the rotating drum 2 , a motor 23 is installed on the outer wall of the vertical plate 1 , and the output shaft of the motor 23 is connected to the pulley 22 in a driving manner through a belt.

[0053] see Figure 9 , the pulley 22 can be directly driven by the motor 23 to rotate, thereby driving the rotating drum 2 to rotate. Compared with the first embodiment, the speed of the rotating drum 2 can be easily controlled.

[0054] To sum up, in the curing process, the difference between the temperature and humidity at different heights inside the drum 2 is reduced by the rotation of the drum 2, and then the air above and below the drum 2 is mixed with the air through the rotation of the piston tube 6. Cyclic exchange further reduces the internal temperature and humidity difference, and maintains the stability of internal te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com