Method and device for recovering waste heat of ammonia-process desulfurization and decarbonization system

A waste heat recovery and ammonia desulfurization technology, applied in separation methods, chemical instruments and methods, and greenhouse gas reduction, etc., can solve the problems of strict storage conditions and no reuse function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

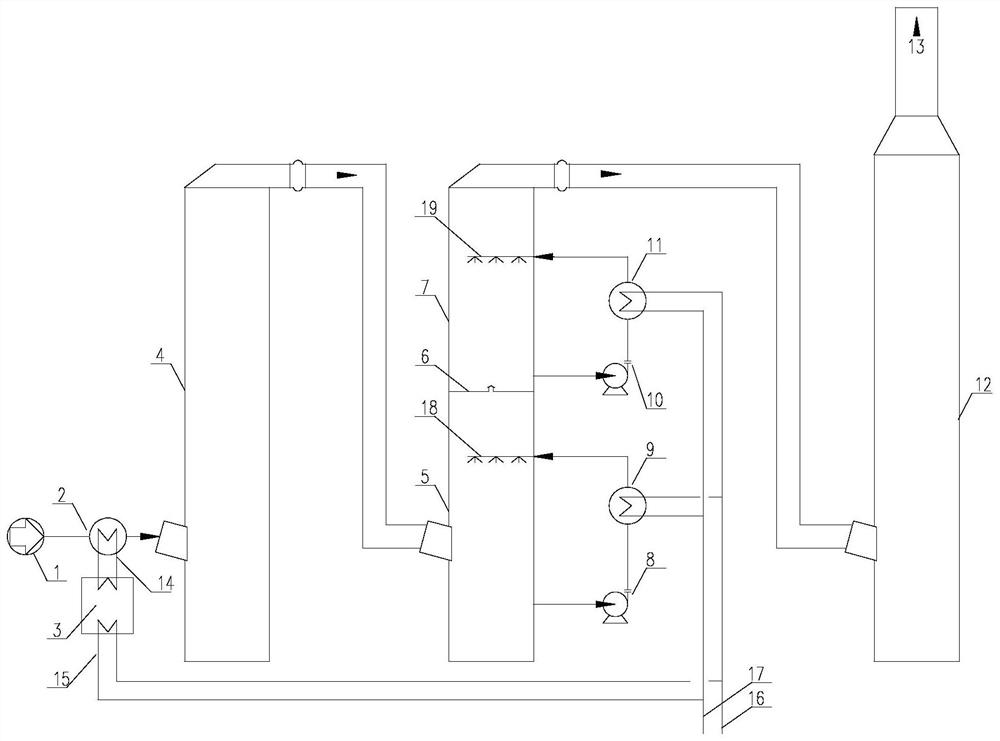

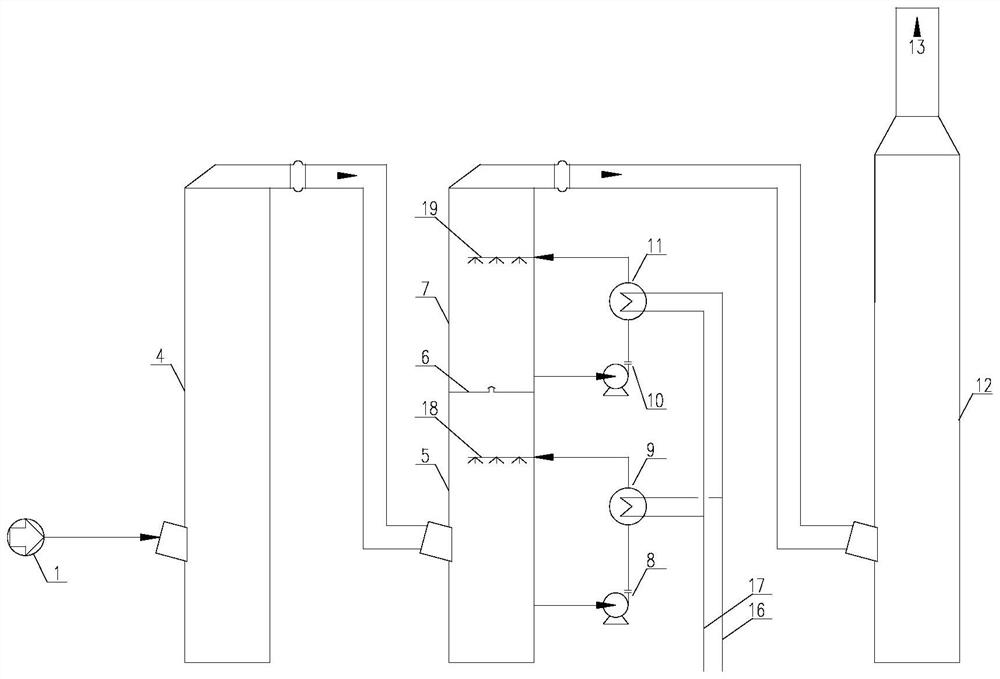

[0040] like figure 1 shown, process gas 1 (ie, coal-fired boiler flue gas, which contains CO 2 , SO 2 , O 2 , N 2 and dust particles) the temperature is 128℃, and the flue gas volume is 857662Nm 3 / h, after passing through the gas heat exchanger 2, it drops to 100 °C and then enters the desulfurization equipment 4. The intermediate medium 14 (ie, water) passes through the gas heat exchanger 2 and then rises from 72 °C to 96 °C, and then goes to the refrigerator 3 to freeze Water 15 was reduced from 17°C to 7°C.

[0041]The temperature of the gas after desulfurization is 45°C, and it enters the cooling device 5 and the decarburization device 7 in turn. The cooling device 5 and the decarburization device 7 are of tower structure and are separated by a liquid collector 6 . The liquid collector 6 is a tray gas cap structure, allowing the gas to enter the decarburization device 7 from the cooling device 5 through the gas cap. Both the cooling equipment 5 and the decarburizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com