Electric furnace flue gas primary dust removal and waste heat recovery system without water cooling flue

A waste heat recovery system and flue technology, applied in the field of industrial flue gas treatment, can solve the problems of consumption, a large amount of high-temperature flue gas heat is not recycled, large electric energy and water, etc., to save water resources, facilitate cleaning, and improve treatment. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

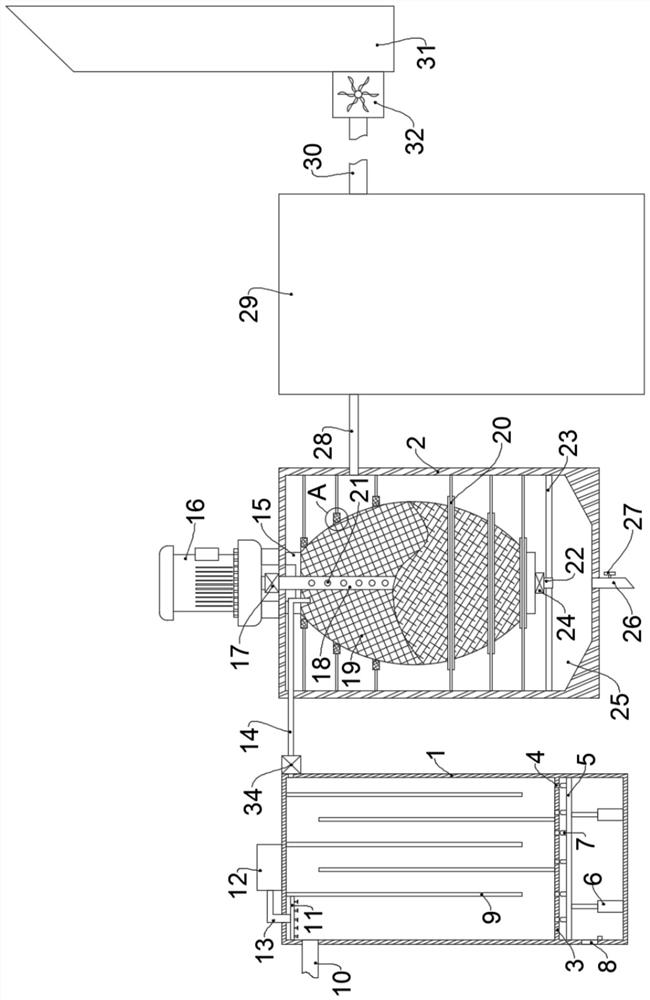

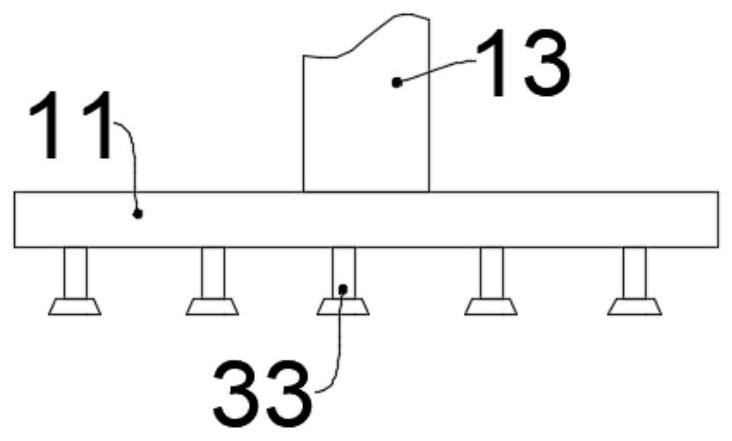

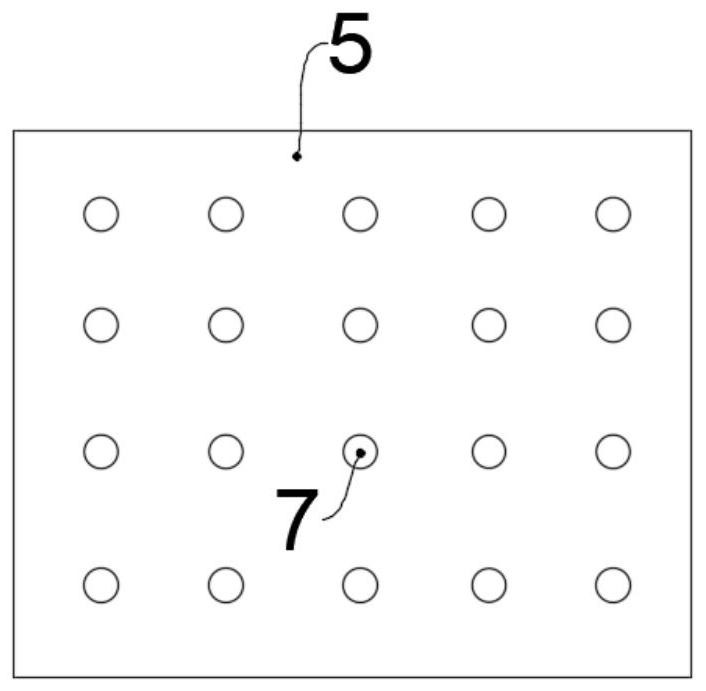

[0030] Such as Figure 1-5 As shown, a primary dust removal and waste heat recovery system for electric furnace flue gas without a water-cooled flue includes a primary treatment box 1, and the right side of the primary treatment box 1 is provided with a dust removal air duct 14 for transmitting electric furnace flue gas. The air duct 14 is provided with a temperature control valve 34 that can be opened and closed according to the temperature control near the position of the primary treatment box 1. The other end of the dust removal air duct 14 is provided with a secondary treatment box 2, and the inside of the secondary treatment box 2 is provided with a The dust removal filter bag 19 for removing dust particles, the ring side of the dust removal filter bag 19 is provided with a plurality of limit rings 20 arranged in parallel, the dust removal filter bag 19 is connected with the limit ring 20, and the middle part of the dust removal filter bag 19 is provided with a The jet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com