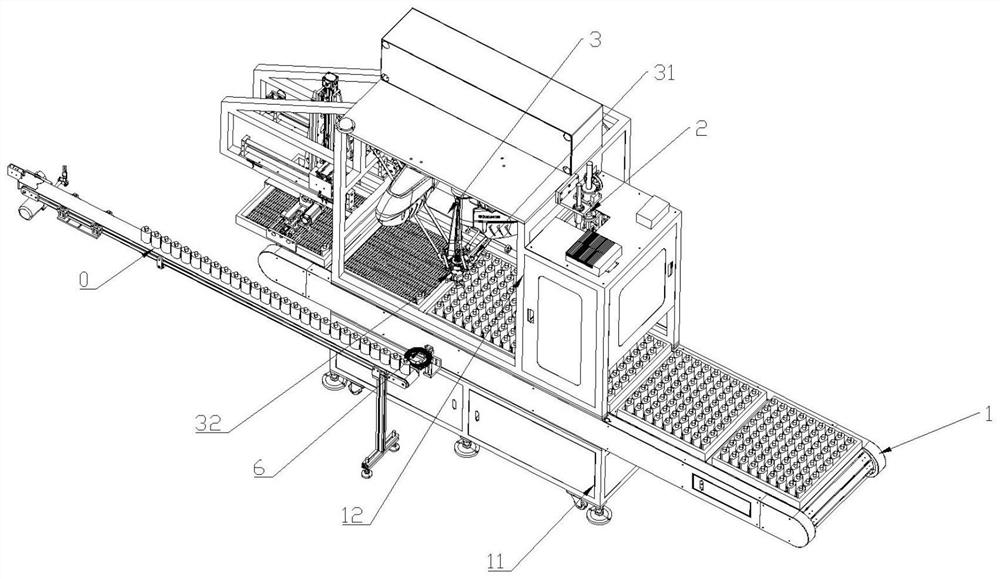

Feeding system for printing equipment

A printing equipment and material feeding technology, which is applied in the field of material feeding system, can solve the problems such as the difficulty of positioning silk screen printing, the difficulty of ensuring the efficiency of manual feeding, and the difficulty of printing special-shaped bottle containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

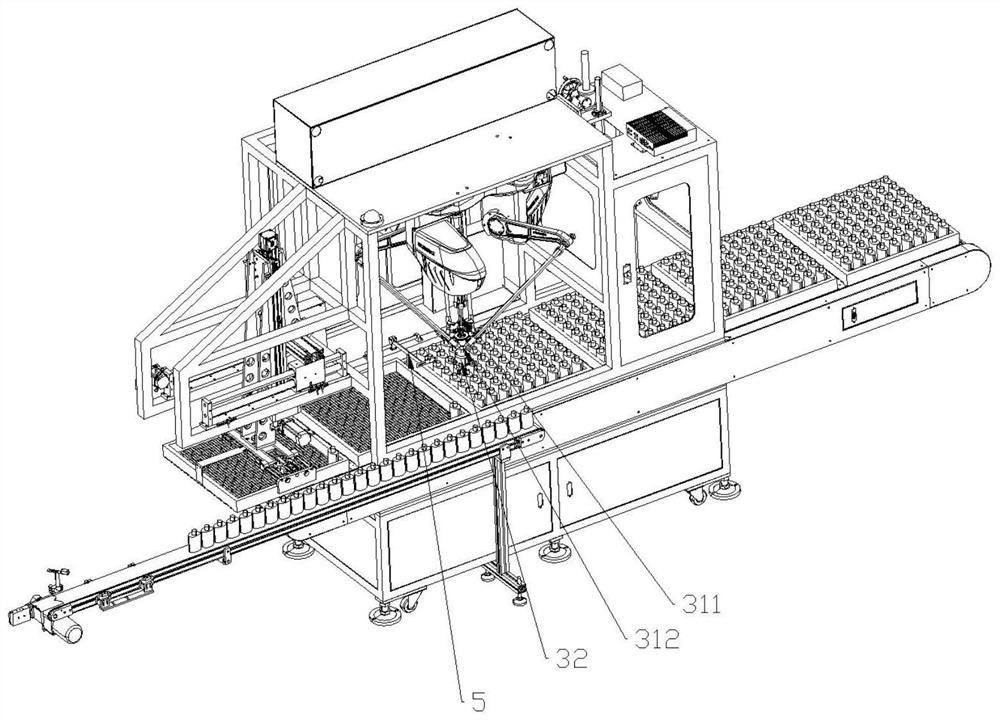

Method used

Image

Examples

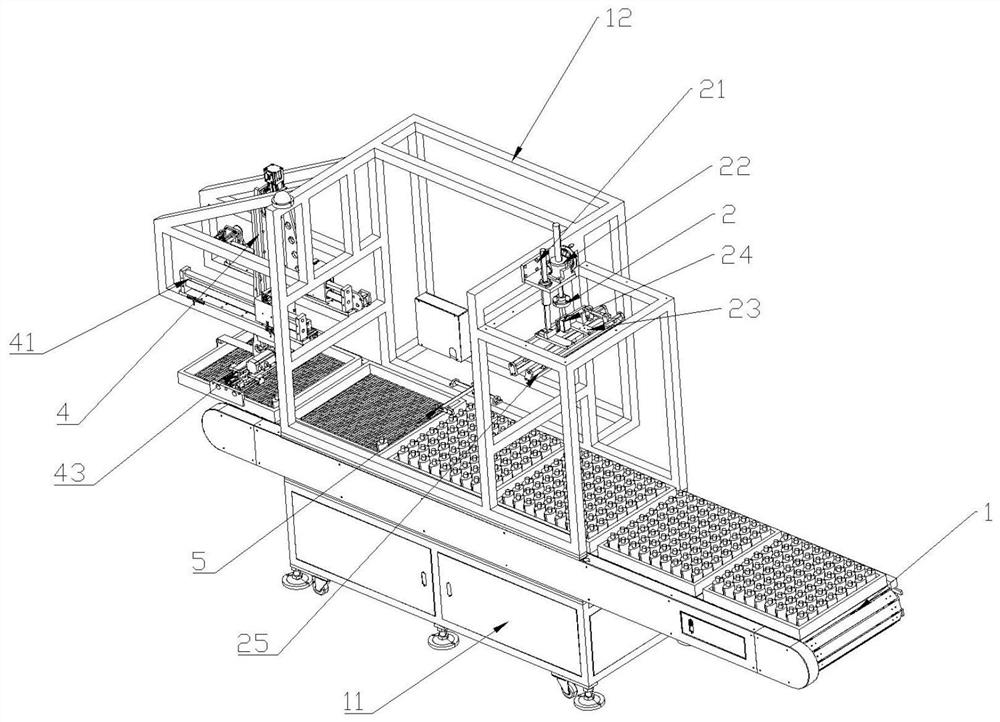

Embodiment 2

[0088] refer to figure 2 , Image 6 and Figure 7 , the present invention also provides a feeding system for printing equipment. On the basis of Embodiment 1, it also includes an empty tray transfer device 4, which is erected on the conveyor belt 1 and located at the empty tray unloading station. , used to remove the empty pallets on the conveyor belt 1 and stack them; the empty pallet transfer device 4 includes a horizontal moving mechanism 41 arranged on the frame 12, and the movable end of the horizontal moving mechanism 41 is provided with A vertical lifting mechanism 42, the movable end of the vertical lifting mechanism 42 is provided with a pallet gripper 43, and the moving direction of the horizontal moving mechanism 41 is the same as the conveying direction of the conveyor belt 1; the pallet gripper 43 includes A pallet gripper 43 bracket, the gripper bracket includes a vertical frame 431 and a horizontal frame 432 vertically arranged with the vertical frame 431 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com