Visual non-corrosion detection method for quickly and accurately judging characteristics of welding area

A welding area and detection method technology, applied in the field of visual non-corrosion detection, can solve the problems of heterogeneous joint corrosion, tissue misjudgment, misjudgment, etc., and achieve the effect of avoiding misjudgment and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

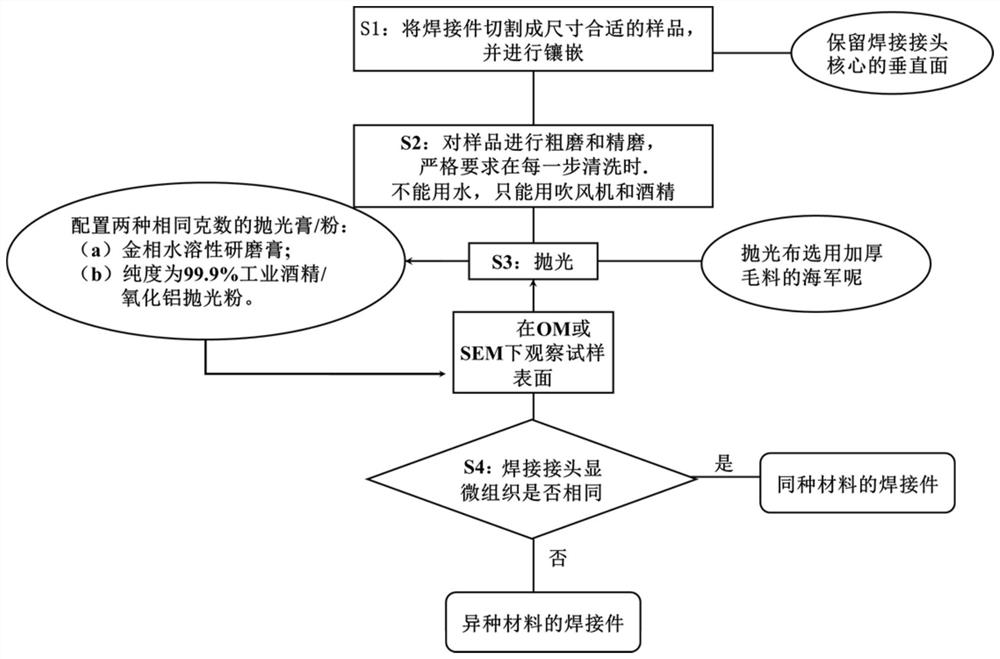

[0020] This embodiment provides a visual non-corrosion detection method for quickly and accurately judging the characteristics of the welding area. The process is as follows figure 1 shown, including the following steps:

[0021] Step 1. Cutting: Cut the welded joint made of Al alloy and Mg alloy of 5 mm thick sheet into a sample of suitable size, and mount it; when cutting and mounting, keep the vertical surface of the core of the welded joint.

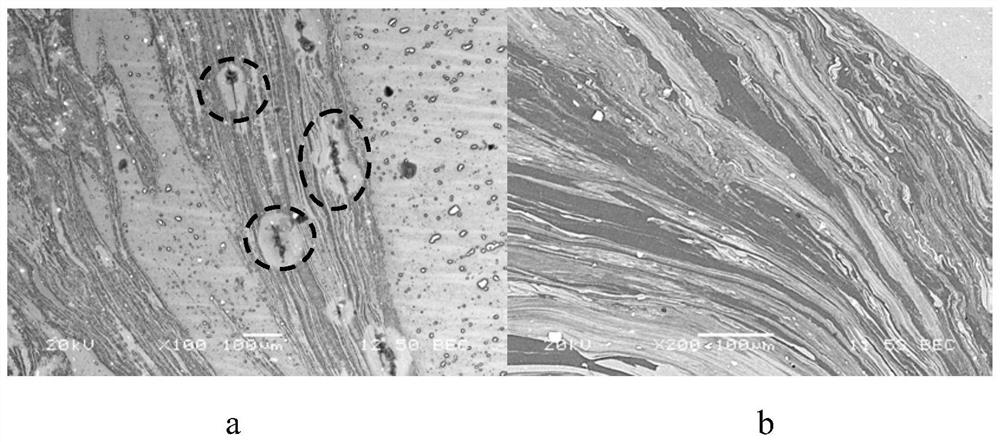

[0022] Step 2. Grinding: Rough grinding and fine grinding are performed on the sample in sequence, and both are cleaned after rough grinding and fine grinding. It is strictly required that water or aqueous solution can not be used in each step of cleaning, only a hair dryer or alcohol can be used. Specifically, the rough grinding method is to use 50-mesh sandpaper to dry-grind the sample, and the fine-grinding method is to use 100, 200, 500, 800, 1000-grit sandpaper to dry-grind the sample in sequence until the surface of the sample ...

Embodiment 2

[0026] This embodiment provides a visual non-corrosion detection method for quickly and accurately judging the characteristics of the welding area. The process is as follows figure 1 shown, including the following steps:

[0027] Step 1. Cutting: Cut the welded joints made of 8mm TRIP steel plates by spot welding together into a sample of suitable size, and mount them; when cutting and mounting, keep the vertical surface of the core of the welded joint.

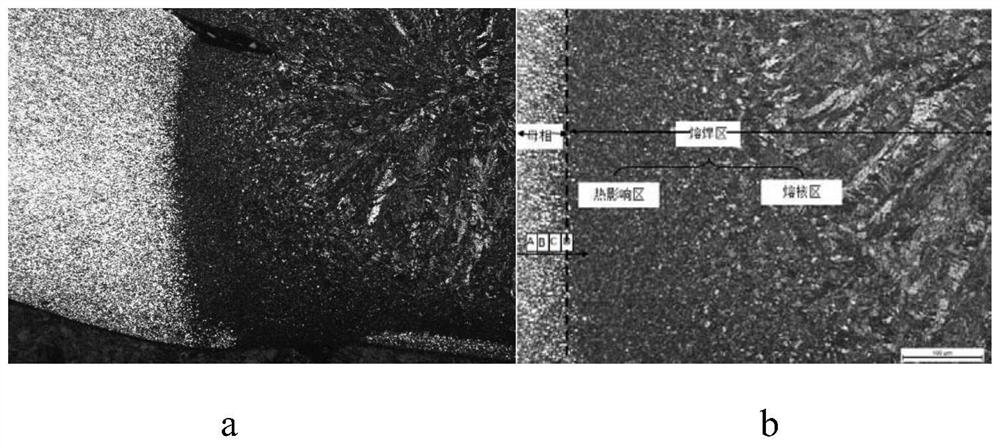

[0028] Step 2. Grinding: Rough grinding and fine grinding are performed on the sample in sequence, and both are cleaned after rough grinding and fine grinding. It is strictly required that water or aqueous solution can not be used in each step of cleaning, only a hair dryer or alcohol can be used. Specifically, the rough grinding method is to use 50-mesh sandpaper to dry-grind the sample, and the fine-grinding method is to use 100, 200, 500, 800, 1000-grit sandpaper to dry-grind the sample in sequence until the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com