Method for detecting quality of flue gas desulfurization agent

A desulfurizer and flue gas technology, applied in chemical analysis by titration, can solve the problems of secondary pollution, corrosion, small absorption, etc., and achieve the effect of simple detection method and reliable detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

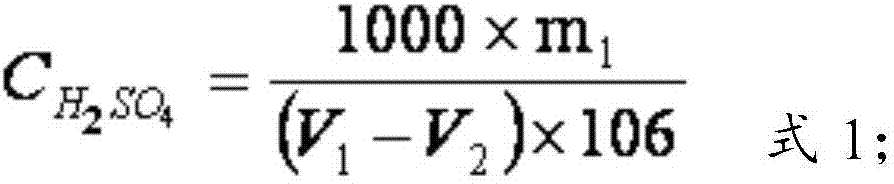

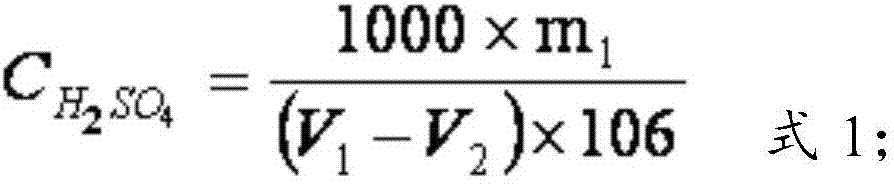

[0056] The preparation of embodiment 1 0.01mol / L sulfuric acid standard solution

[0057] Accurately weigh 10g of analytically pure concentrated sulfuric acid, place it in a 1000mL volumetric flask, add distilled water to dilute to the mark, shake well, then set the volume to 1000L, shake well, and prepare a sulfuric acid standard solution with a theoretical concentration of 0.01mol / L.

Embodiment 2

[0058] The demarcation of embodiment 2 sulfuric acid standard solution

[0059] Weigh 0.0250g of standard sodium carbonate that has been dried at 200°C for 1.5 hours and cooled to room temperature in a desiccator, put it in a 250mL conical flask, dissolve it in 100mL of newly boiled distilled water, and add 7-8 drops of bromocresol Green-methyl red indicator, titrated with the sulfuric acid standard solution prepared in embodiment 1 until the solution was yellow, boiled for 2 minutes, continued titration after cooling until the solution was dark red, and the consumed volume of the sulfuric acid standard solution was recorded as 24.05mL; Carry out the blank test that does not add sodium carbonate under condition, the consumption volume of record sulfuric acid standard solution is 0.37mL, calculate the actual concentration of the sulfuric acid standard solution that embodiment 1 prepares according to above-mentioned formula 1 and be 0.009958mol / L, divide and take 100mL sulfuric a...

Embodiment 3

[0060] The quality measurement of embodiment 3 flue gas desulfurizer

[0061] weigh m 2 (0.5 ~ 10g) flue gas desulfurizer into the conical flask, accurate to 0.0001g, add distilled water to dissolve, then set the volume to 100mL, shake well, get the solution to be tested, the volume of the solution to be tested is V 3 (100 mL).

[0062] Transfer V 4 (1~20mL) above-mentioned solution to be tested is placed in 150mL Erlenmeyer flask, adds 50mL distilled water, after shaking up, add 3 drops of methyl red indicator, make solution color be light yellow-green, use the sulfuric acid prepared in Example 1 Titrate the standard solution until the solution is orange-yellow and record it as the titration end point, and record the volume of the sulfuric acid standard solution consumed as V 5 , carry out a blank test without adding the solution to be tested under the same conditions, and record the volume of the sulfuric acid standard solution consumed as V 6 .

[0063] Calculate the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com