Process for preparing barium chloride by chlorating and calcining carbonate-type barium ore

A carbonate type, chlorinated roasting technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of long-distance transportation and storage of hydrochloric acid, low chloride effective utilization, production Cost increase and other issues, to achieve the effect of low cost, high effective utilization, and reduced transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment:

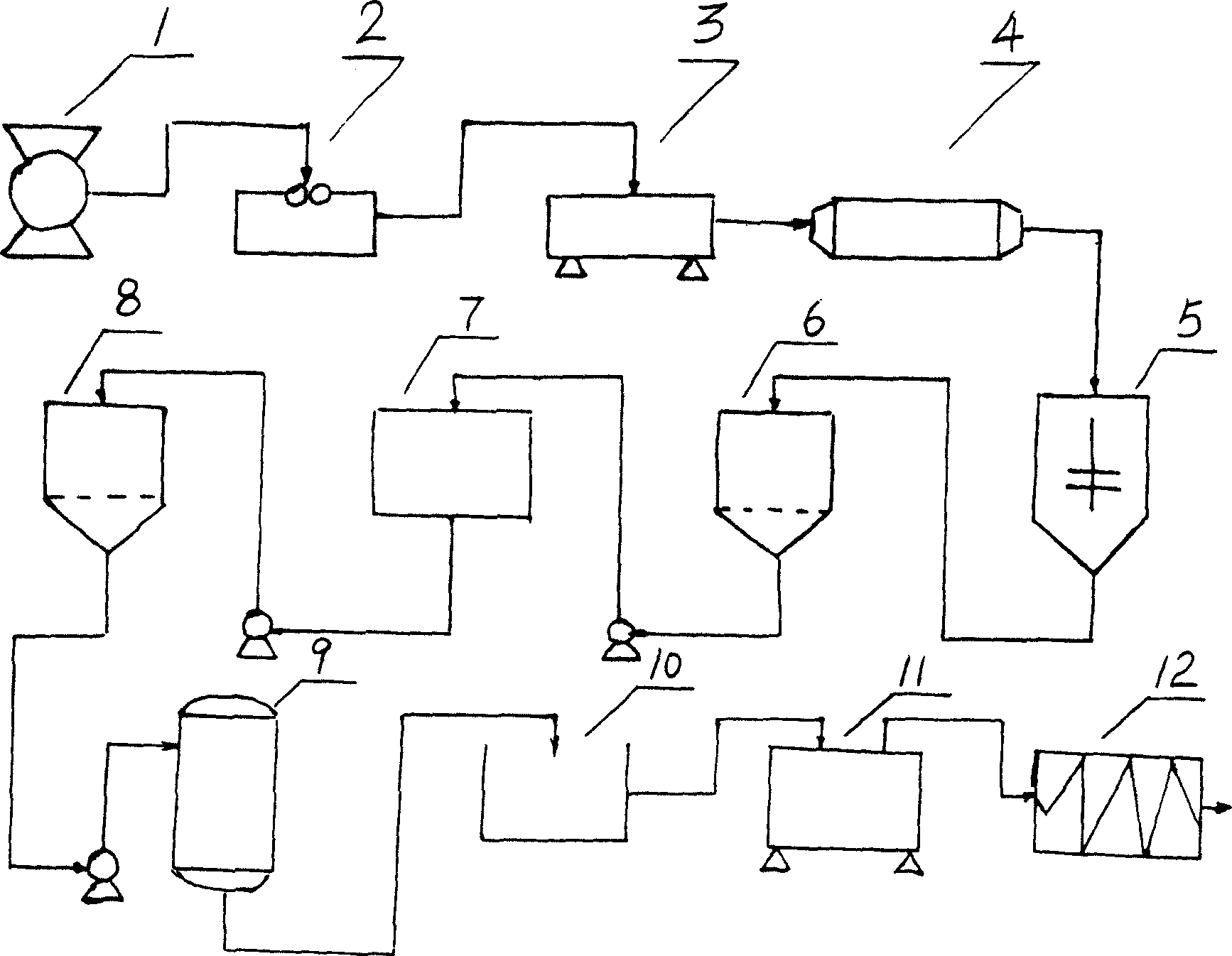

[0028] like figure 1 Shown, the present invention mainly carries out successively by following steps:

[0029] a. Put the carbonate-type barium ore in the crusher 1 for crushing, and then crush it through the crusher 2, generally crushing it into 60-120 mesh;

[0030] B. the pulverized carbonate type barium ore and calcium chloride or magnesium chloride fine powder are stirred and mixed in the mixer 3 in the ratio of 1: 0.3~0.8 by pure substance weight ratio;

[0031] c. Send the uniformly mixed mixture into the tunnel kiln or rotary kiln 4, and roast it at a temperature of 500°C to 1500°C. The general roasting time is 4 hours, so that the mixture can fully react to form barium chloride and calcium carbonate or magnesium carbonate. body;

[0032] d. Put the melt of barium chloride and calcium carbonate or magnesium carbonate out of the furnace into the leaching device 5, then add ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap